System-on-Chip

BY

JULIANA GJANCI

B.S. University of Illinois at Chicago, 2006

THESIS

Submitted as partial fulfillment of the requirements

For the degree of Master of Science in Electrical and Computer Engineering

In the Graduate College of the

University of Illinois at Chicago, 2008

Chicago, Illinois

i

© Copyright by JULIANA GJANCI 2008

All Rights Reserved

ii

ABSTRACT

On-Chip Voltage Regulation for Power Management in System-On-Chip

JULIANA GJANCI

The scaling of minimum feature sizes down to nanometer range and the spiraling

frequencies in GHz scale has lead to system-on-a-chip (SOC) implementation for many

emerging applications. To utilize the unprecedented computing power of over billion transistors

on each SOC die many integrated circuit (IC) implementations have been adopting multi-core

strategies instead of single-core implementation. It is predicted that a network-on-chip (NOC)

communication fabric will be used in such multi-core SOCs. In the coming decades, market

competition among different design paradigms and implementation strategies will resolve itself

as their technical and economical costs and benefits are being widely investigated and

documented. However, ITRS and all the recent studies and roadmaps have indicated that in all

future micro- and nano-electronic circuits and systems power distribution, reliability and

management issues are expected to become the most serious bottlenecks. The frequency

increase as well as convergence towards mixed-signal systems has aggravated the difficulties of

supplying clean power to integrated circuits. Power consumption has a critical impact on IC

performance, and therefore, its management is important. Ineffective power management causes

lower chip performance, increases area and makes the design nonfunctional. Therefore, more

than ever, power integrity is vital in the successful design of today’s electronic systems.

iii

With the growing power management concern in high performance microprocessor

designs the requirement for efficient voltage regulation has become a very critical design

challenge. The objectives of this thesis are to investigate the scopes and techniques for on-chip

voltage regulation in SOC design, and to synthesize a methodology for on-chip voltage

regulator module (VRM) implementation. The approach is primarily based on existing voltage

regulator topologies that are used for off-chip voltage regulation. Here on-chip implementation

and performance of these voltage regulators will be investigated. In order to accomplish these

goals, the following specific tasks have been attempted in this research initiative:

• Perform in-depth analysis of all the available regulator topologies that have been

used for off-chip voltage regulation at the printed circuit board (PCB) level.

• Investigate the best topology suitable for on-chip implementation.

• Synthesize an on-chip design strategy that provides better regulator efficiency and

power management, and minimizes design complexity and cost.

• Investigate the performance implications of placing the regulators on chip.

Aggressive power management is necessary since more devices are packed on a single

processor chip operating at high frequencies. Analysis indicates that a DC/DC step-down

voltage regulator module (VRM) is needed to deliver power from the source to the load, to

provide constant voltage to the load, control power fluctuations, and prevent damages to loads

connected to the supply. Traditionally voltage regulators are off-chip devices due to the large

inductive and capacitive filter elements that they employ. They operate at low switching

frequencies, typically lower than 5MHz, and as a result they fail to perform fast voltage

transitions. Furthermore, on-chip implementation of such regulators employing large inductive

iv

and capacitive elements is not practical due to their complexity and high cost. This is especially

a bottleneck when multiple on-chip power domains are needed.

The methodology proposed in this thesis includes a two-stage converter with the first

stage consisting of a switching voltage regulator located off-chip and the second stage

consisting of a tree linear regulator topology located on-chip. This approach proves to be

efficient, simple, and less costly compared to other options that offer total on-chip integration of

switching regulators. The proposed approach combines the advantages of both voltage regulator

topologies – switching and linear, and results in one hybrid design that is suitable for multi-core

SOC implementations.

v

ACKNOWLEDGMENTS

First, I would like to thank God for all that He has endowed upon me and all the

opportunities that He has presented to me in life. I would like to thank my parents for their

encouragement and support and for creating the opportunity for me to study in the United

States. None of my success would have been possible without them.

I would like to express my gratitude and deepest appreciation to my advisor, Dr. Masud

H. Chowdhury, for his advice, help, support, motivating suggestions and encouragement during

my research. His endless energy and enthusiasm in research has motivated all of his students,

including me. I wish him all the best. It was an honor to have Dr. Ashfaq Khokhar and Dr.

Kaijie Wu in my thesis committee. I am grateful for their comments and objective directions to

complete the Masters Thesis work.

Last but not least, I would like to extend my gratitude to all of the people who have

helped and inspired me during my research, my friends and colleagues especially Nima Jahedi,

who volunteered their time and effort to help me.

vi

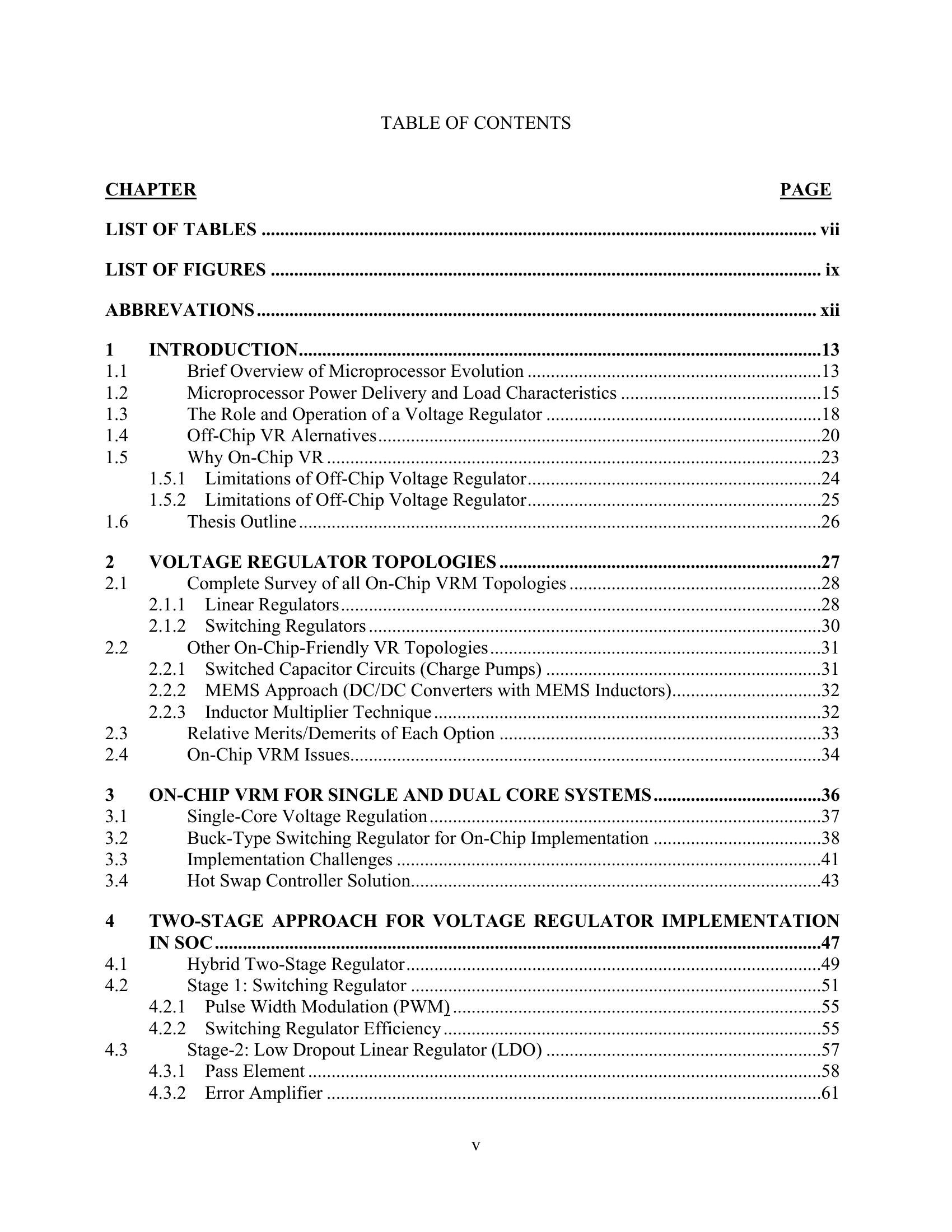

TABLE OF CONTENTS

CHAPTER PAGE

LIST OF TABLES………………………………………………………………………………………………………..vii

LIST OF FIGURES……………………………………………………………………………………………………….ix

ABBREVATIONS…………………………………………………………………………………………………………xii

1 INTRODUCTION………………………………………………………………………………………………….13

1.1 Brief Overview of Microprocessor Evolution………………………………………………………13

1.2 Microprocessor Power Delivery and Load Characteristics…………………………………….15

1.3 The Role and Operation of a Voltage Regulator…………………………………………………..18

1.4 Off-Chip VR Alernatives…………………………………………………………………………………..20

1.5 Why On-Chip VR…………………………………………………………………………………………….23

1.5.1 Limitations of Off-Chip Voltage Regulator………………………………………………………24

1.5.2 Limitations of Off-Chip Voltage Regulator………………………………………………………25

1.6 Thesis Outline………………………………………………………………………………………………….26

2 VOLTAGE REGULATOR TOPOLOGIES……………………………………………………………27

2.1 Complete Survey of all On-Chip VRM Topologies………………………………………………28

2.1.1 Linear Regulators………………………………………………………………………………………….28

2.1.2 Switching Regulators…………………………………………………………………………………….30

2.2 Other On-Chip-Friendly VR Topologies……………………………………………………………..31

2.2.1 Switched Capacitor Circuits (Charge Pumps)…………………………………………………..31

2.2.2 MEMS Approach (DC/DC Converters with MEMS Inductors)…………………………..32

2.2.3 Inductor Multiplier Technique………………………………………………………………………..32

2.3 Relative Merits/Demerits of Each Option……………………………………………………………33

2.4 On-Chip VRM Issues………………………………………………………………………………………..34

3 ON-CHIP VRM FOR SINGLE AND DUAL CORE SYSTEMS………………………………36

3.1 Single-Core Voltage Regulation…………………………………………………………………………37

3.2 Buck-Type Switching Regulator for On-Chip Implementation………………………………38

3.3 Implementation Challenges……………………………………………………………………………….41

3.4 Hot Swap Controller Solution…………………………………………………………………………….43

4 TWO-STAGE APPROACH FOR VOLTAGE REGULATOR IMPLEMENTATION

IN SOC………………………………………………………………………………………………………………….47

4.1 Hybrid Two-Stage Regulator……………………………………………………………………………..49

4.2 Stage 1: Switching Regulator…………………………………………………………………………….51

4.2.1 Pulse Width Modulation (PWM)…………………………………………………………………….55

4.2.2 Switching Regulator Efficiency………………………………………………………………………55

4.3 Stage-2: Low Dropout Linear Regulator (LDO)…………………………………………………..57

4.3.1 Pass Element………………………………………………………………………………………………..58

4.3.2 Error Amplifier…………………………………………………………………………………………….61

v

4.3.3 Power Supply Ripple Rejection………………………………………………………………………62

4.3.4 Efficiency of Low Dropout Linear Regulator……………………………………………………63

4.4 Simulation Results and Analysis………………………………………………………………………..64

5 FUTURE WORK…………………………………………………………………………………………………..74

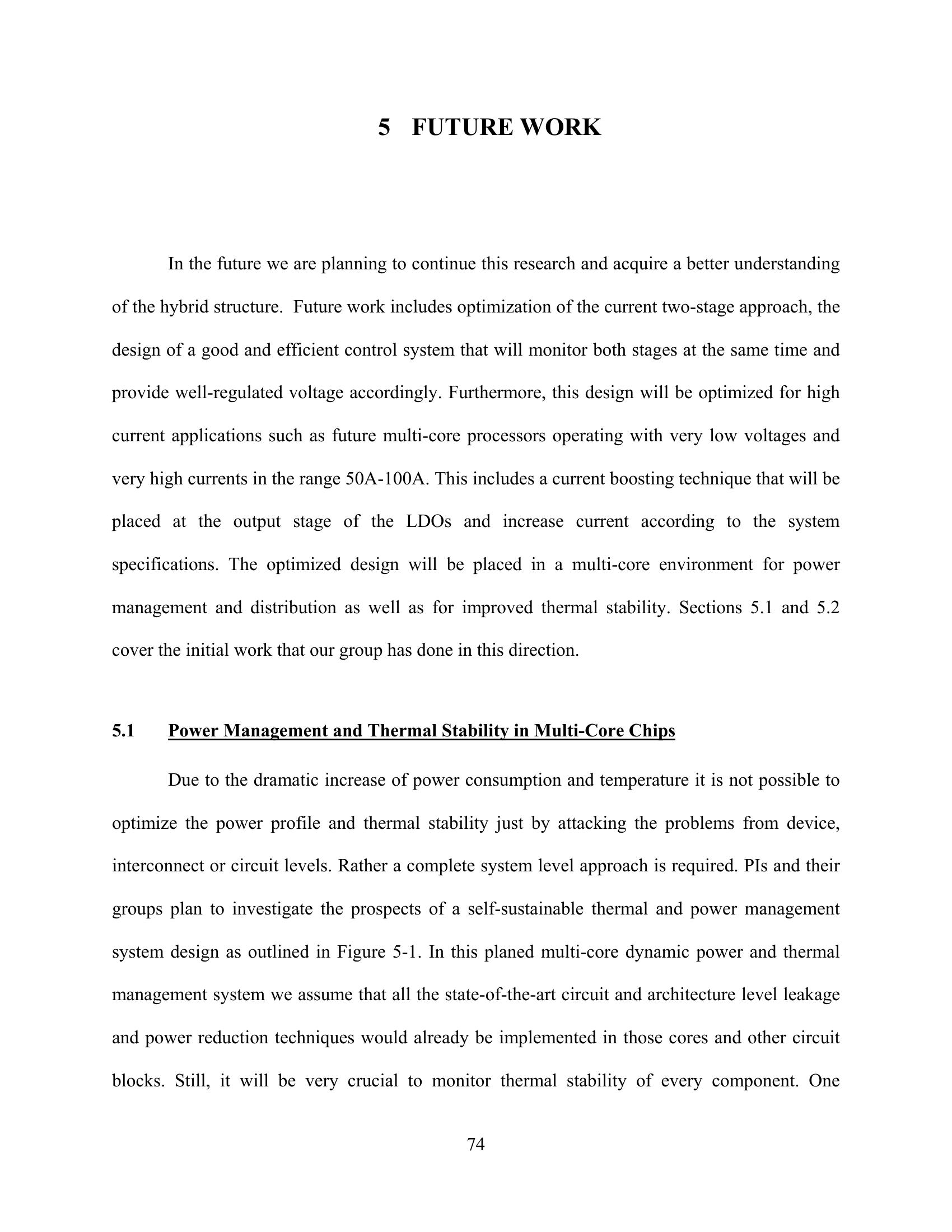

5.1 Power Management and Thermal Stability in Multi-Core Chips…………………………….74

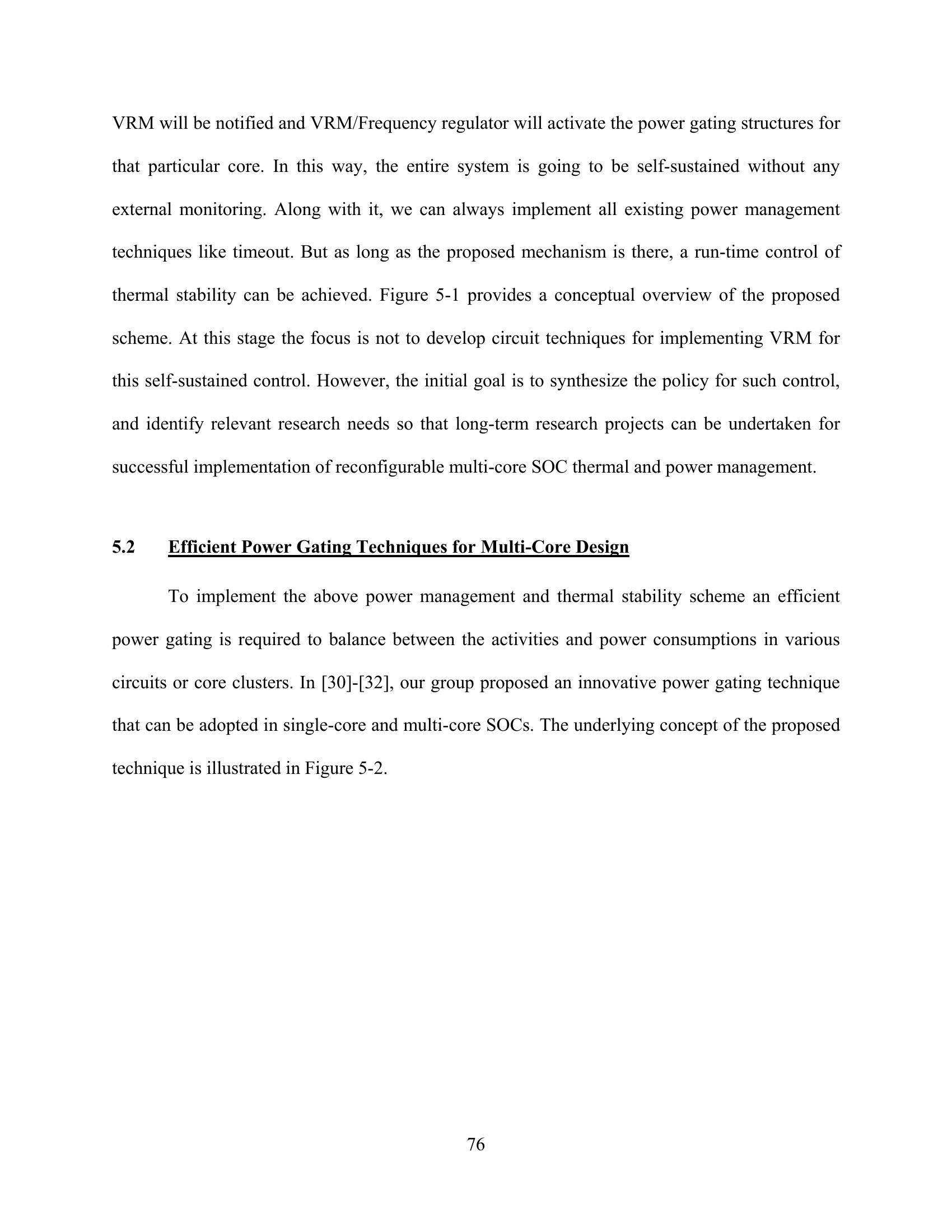

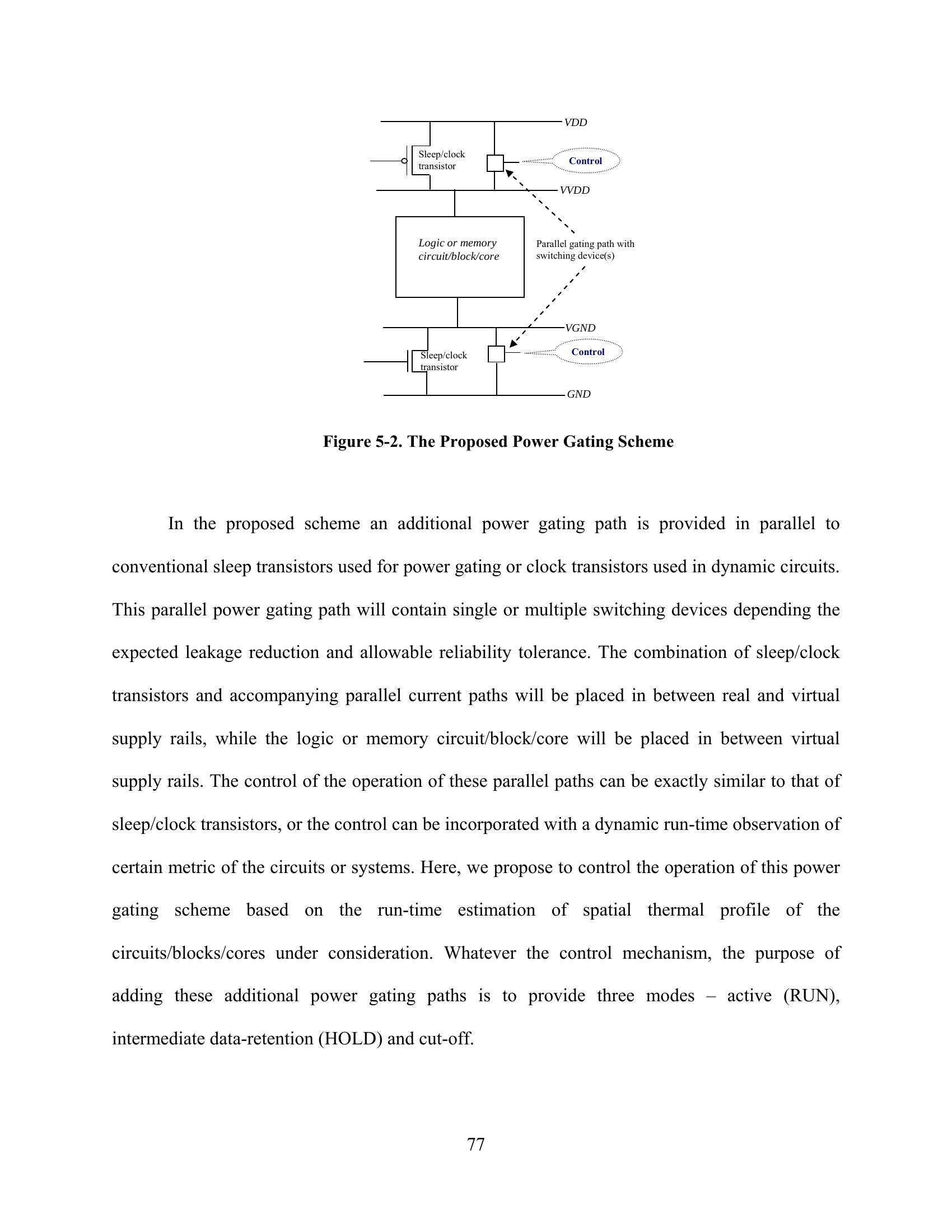

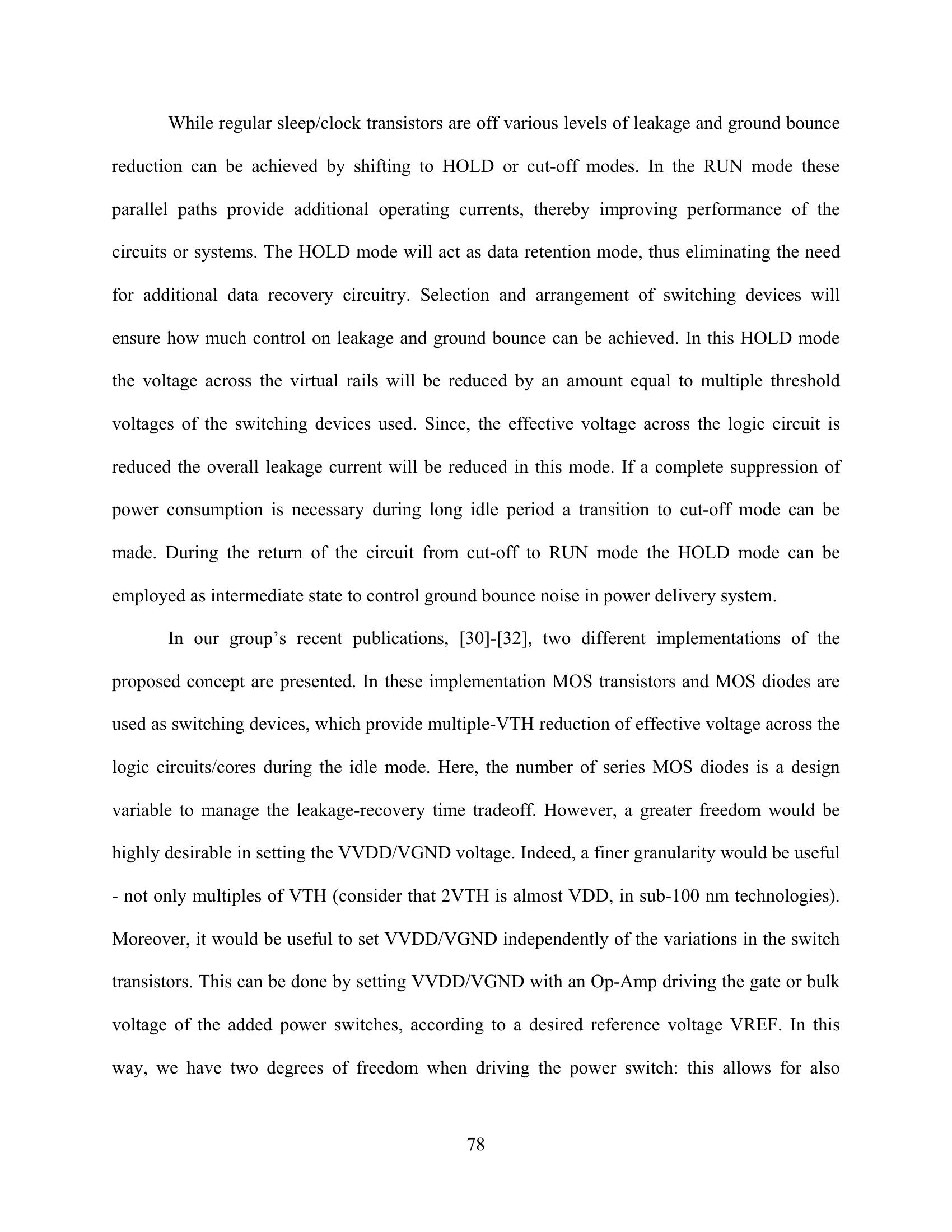

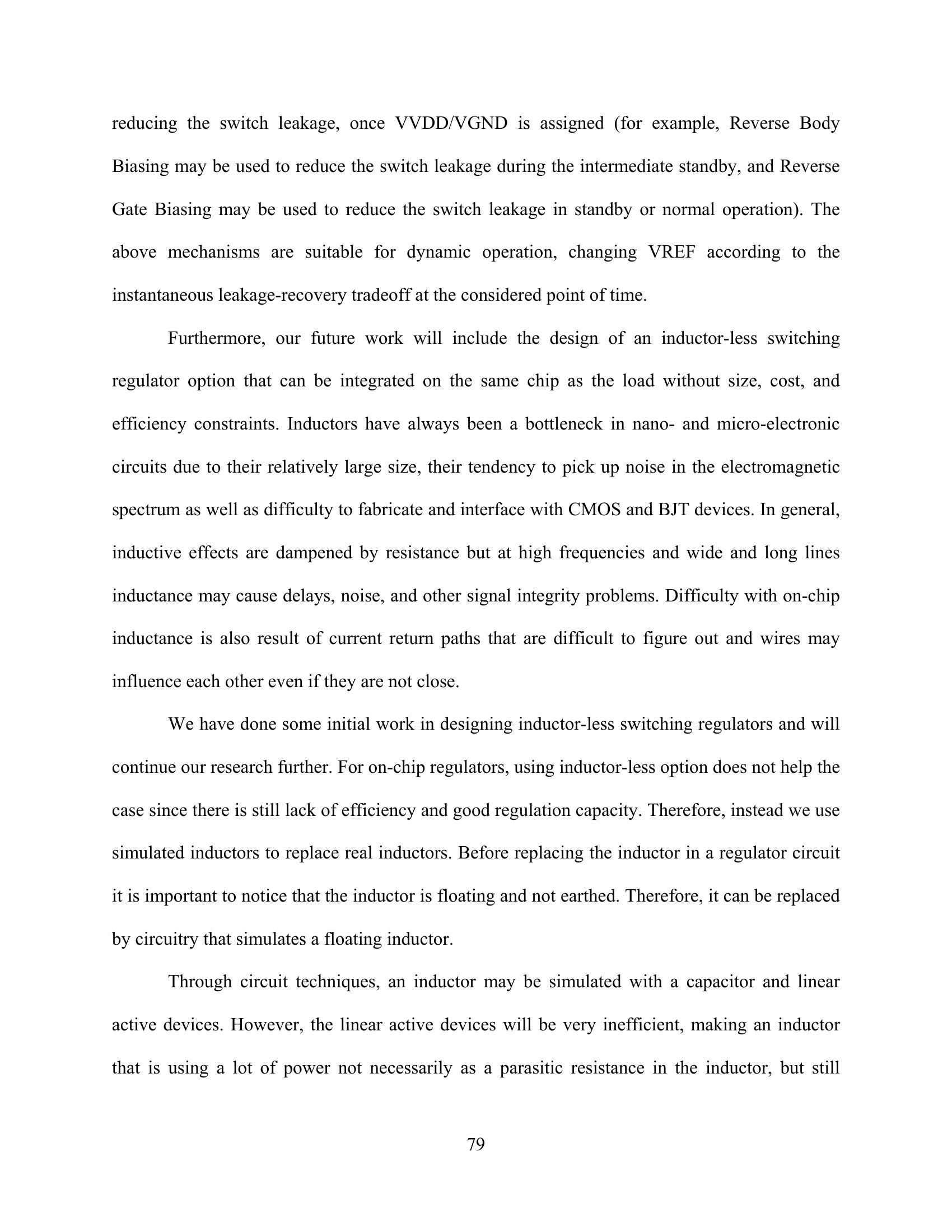

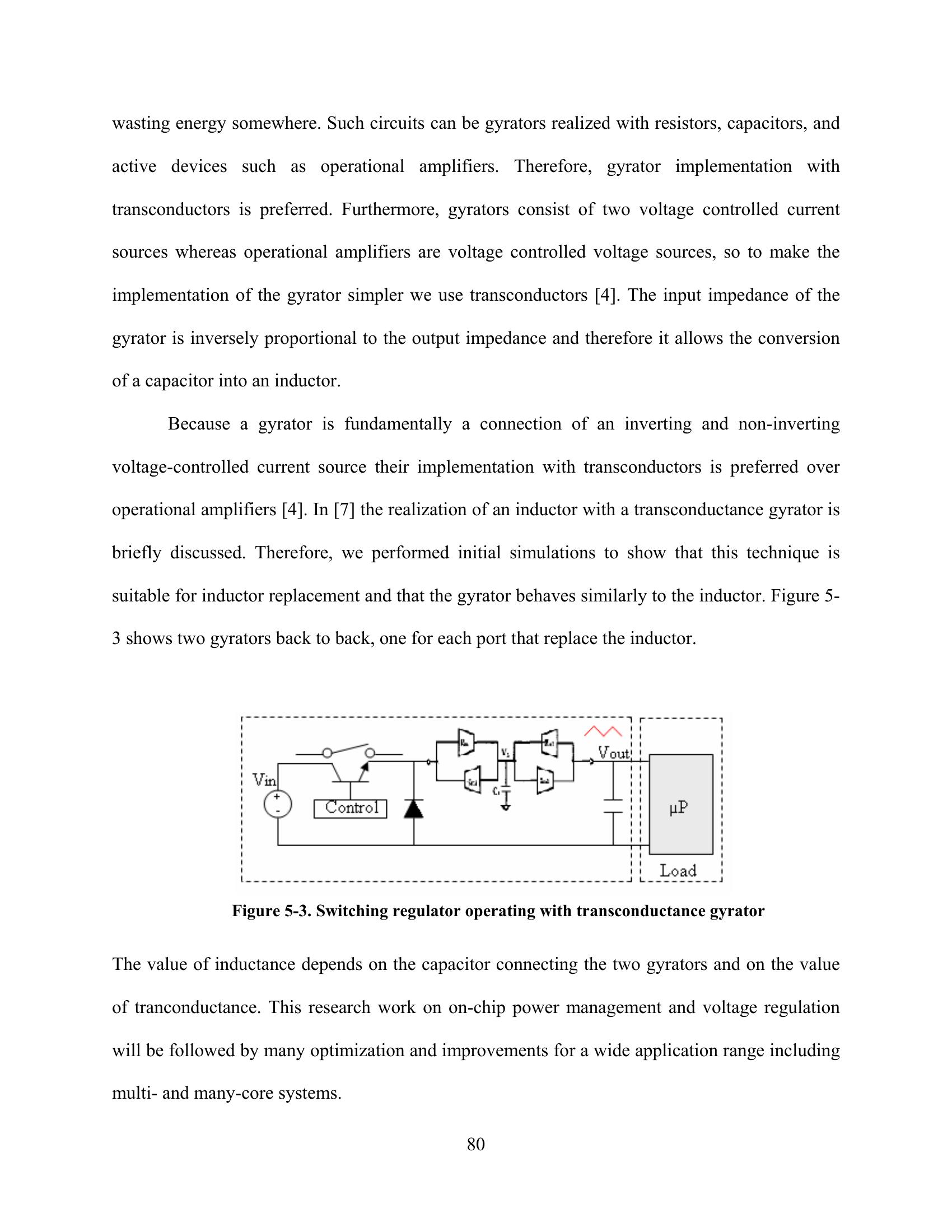

5.2 Efficient Power Gating Techniques for Multi-Core Design……………………………………76

6 CONCLUSION……………………………………………………………………………………………………..81

REFERENCES………………………………………………………………………………………………………………83

vi

LIST OF TABLES

Table 1. Switching Regulator Circuit Parameters…………………………………………………………54

Table 2. LDO regulator efficiency……………………………………………………………………………..64

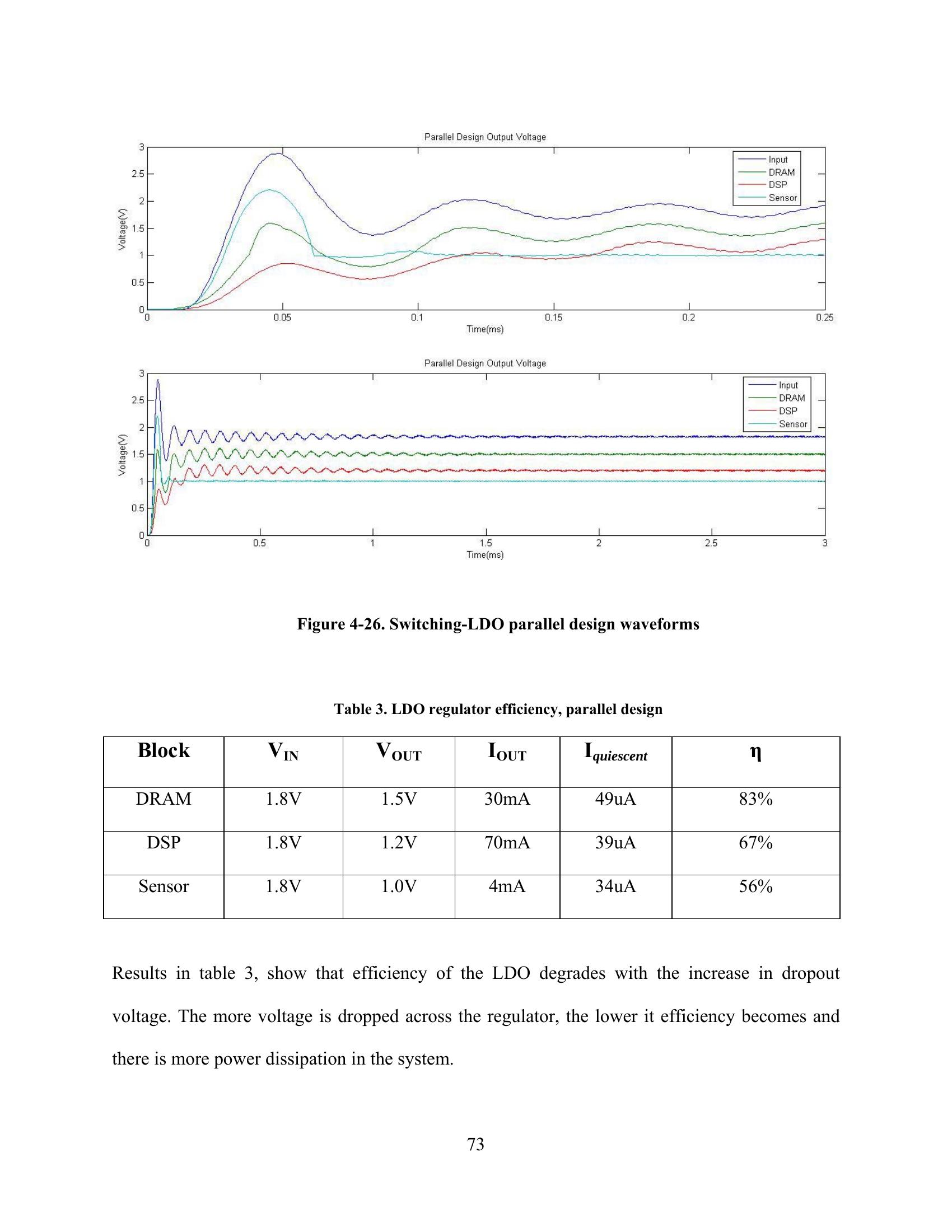

Table 3. LDO regulator efficiency, parallel design………………………………………………………73

vii

LIST OF FIGURES

FIGURE PAGE

Figure 1-1. Exponential increase of transistors per die………………………………………………….13

Figure 1-2. Current and voltage roadmap for present and future microprocessors……………14

Figure 1-3. Voltage regulator providing power to the microprocessor……………………………16

Figure 1-4. Voltage regulator (VR-down) on motherboard……………………………………………16

Figure 1-5. Voltage regulator module, VRM……………………………………………………………….17

Figure 1-6. Voltage regulator operation………………………………………………………………………19

Figure 1-7. Laptop power supply……………………………………………………………………………….21

Figure 1-8. Circuit of a conventional buck converter……………………………………………………22

Figure 1-9. Circuit of a synchronous buck converter……………………………………………………22

Figure 1-10. Circuit of a multi-phase buck converter……………………………………………………23

Figure 1-11. Off-chip voltage regulator module…………………………………………………………..24

Figure 1-12. On-chip voltage regulator module…………………………………………………………..25

Figure 2-1. Power distribution noise in a system on a chip……………………………………………27

Figure 2-2. Linear regulator………………………………………………………………………………………28

Figure 2-3. Switching regulator…………………………………………………………………………………30

Figure 2-4. Switched capacitor regulator…………………………………………………………………….31

Figure 2-5. Switching regulator employing inductor multiplier……………………………………..32

Figure 3-1. Intel dual core processor, from Intel website………………………………………………36

Figure 3-2. Switching Regulator with hysteresis control……………………………………………….39

Figure 3-3. Inductor Current in Switching Converter……………………………………………………40

ix

Figure 3-4. Regulator off-chip a) without controller and b) with controller…………………….43

Figure 3-5. Regulator and controller on-chip………………………………………………………………44

Figure 3-6. Inrush current effects in the supply and load………………………………………………45

Figure 3-7. Inrush current protection………………………………………………………………………….45

Figure 4-1. STA2052, System-on-chip, from Nikkei Electronics Asia……………………………47

Figure 4-2. Two-stage conversion……………………………………………………………………………..49

Figure 4-3. Switching regulator…………………………………………………………………………………51

Figure 4-4. Switching regulator with switch ON………………………………………………………….52

Figure 4-5. Switching regulator with switch OFF………………………………………………………..52

Figure 4-6. PWM, duty cycle of the switching regulator………………………………………………53

Figure 4-7. Voltage drain-source ,V , waveform………………………………………………………..53

DS

Figure 4-8. Waveform of current through PMOS transistor…………………………………………..53

Figure 4-9. Waveform of current through diode…………………………………………………………..53

Figure 4-10. Current through inductor/output current…………………………………………………..54

Figure 4-11. Voltage ripple dependency on inductor size……………………………………………..56

Figure 4-12. Switching regulator efficiency………………………………………………………………..57

Figure 4-13. Linear dropout regulator………………………………………………………………………..58

Figure 4-14. Current-Voltage characteristics……………………………………………………………….60

Figure 4-15. Class-A amplifier………………………………………………………………………………….62

Figure 4-16. Stage-1, switching regulator……………………………………………………………………64

Figure 4-17. Switching regulator output waveforms…………………………………………………….65

Figure 4-18. Transient response…………………………………………………………………………………66

Figure 4-19. Switching-LDO building block……………………………………………………………….67

Figure 4-20. Switching-LDO building block waveforms………………………………………………67

Figure 4-21. Switching-LDO tree design…………………………………………………………………….68

x

Figure 4-22. Switching-LDO tree design waveforms……………………………………………………69

Figure 4-23. Switching-LDO tree design quiescent waveforms……………………………………..70

Figure 4-24. Switching-LDO tree design load transient waveform…………………………………71

Figure 4-25. Switching-LDO tree design…………………………………………………………………….72

Figure 4-26. Switching-LDO parallel design waveforms………………………………………………73

Figure 5-1. Multi-core/multi-block Dynamic Power Management System……………………..75

Figure 5-2. The Proposed Power Gating Scheme…………………………………………………………77

Figure 5-3. Switching regulator operating with transconductance gyrator……………………….80

xi

ABBREVATIONS

AC Alternating Current

BJT Bipolar Junction Transistor

CMOS Complementary Metal-Oxide-Semiconductor

DC Direct Current

DRAM Dynamic Random Access Memory

EMI Electromagnetic Interference

IC Integrated Circuit

ITRS International Technology Roadmap Semiconductor

LDO Low Dropout

LR Linear Regulator

MEMS Micro-Electro-Mechanical Systems

MOSFET Metal-Oxide-Semiconductor-Field-Effect-Transistor

NMOS N-channel Metal-Oxide-Semiconductor

PCB Printed Circuit Board

PDN Power Delivery Network

PMOS P-channel Metal-Oxide-Semiconductor

PSRR Power Supply Rejection Ratio

PWM Pulse Width Modulation

R Drain-to-Source Resistance

DS

SOC System-on-Chip

UIC University of Illinois at Chicago

VR Voltage Regulator

VRM Voltage Regulator Module

xii

1 INTRODUCTION

1.1 Brief Overview of Microprocessor Evolution

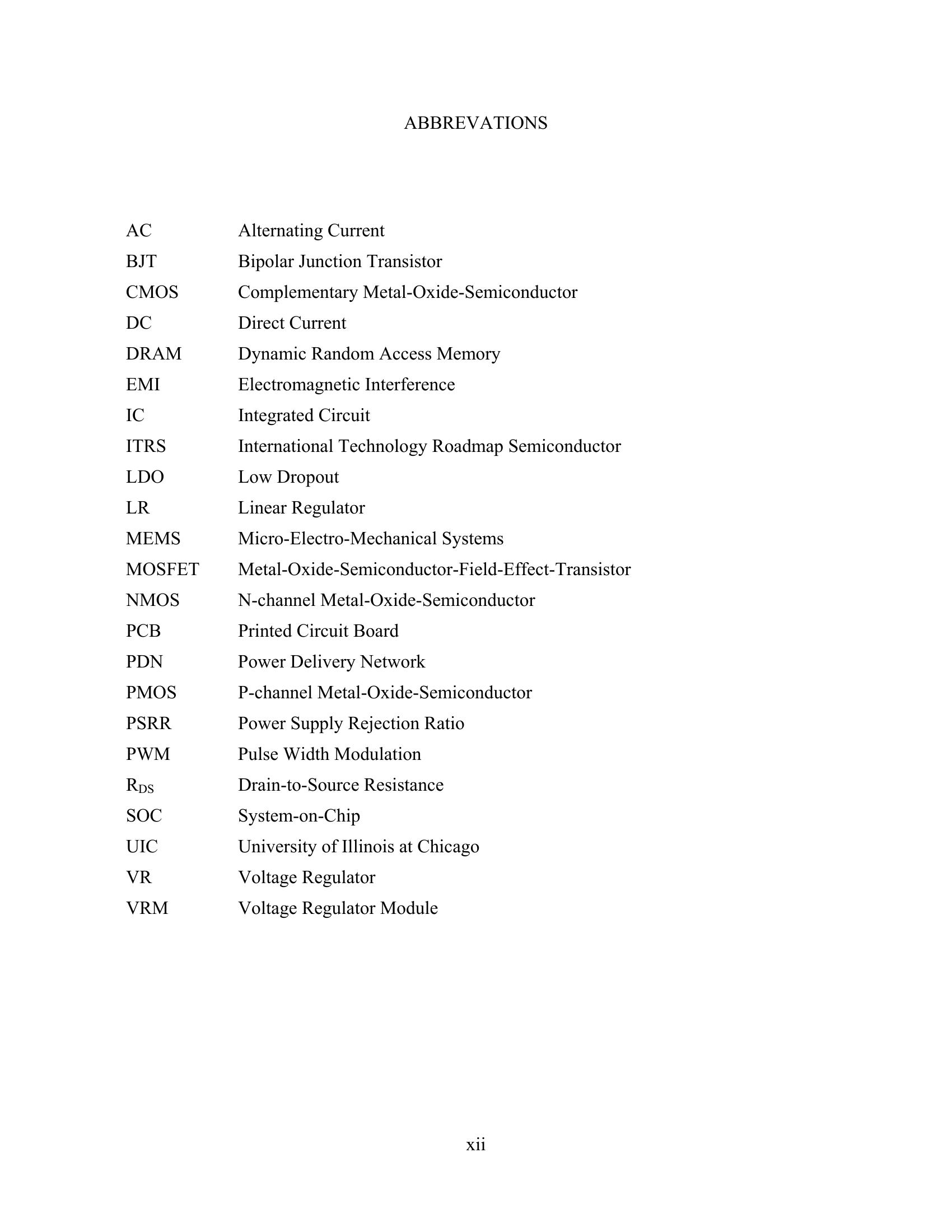

Since the birth of the microprocessor the industry has continued to innovate and improve

performance. Upgrading microprocessor performance requires packing more transistors on a

chip, which necessitates a very sophisticated process technology. As Intel co-founder Gordon E.

Moore predicted, transistor density on an integrated circuit has doubled almost every two years

in the past decade, which means that semiconductor technology has also doubled its

effectiveness, as shown in Figure 1-1.

Figure 1-1. Exponential increase of transistors per die

(Intel Material Technology Operation 2004, by Ed Stanford, Intel)

13

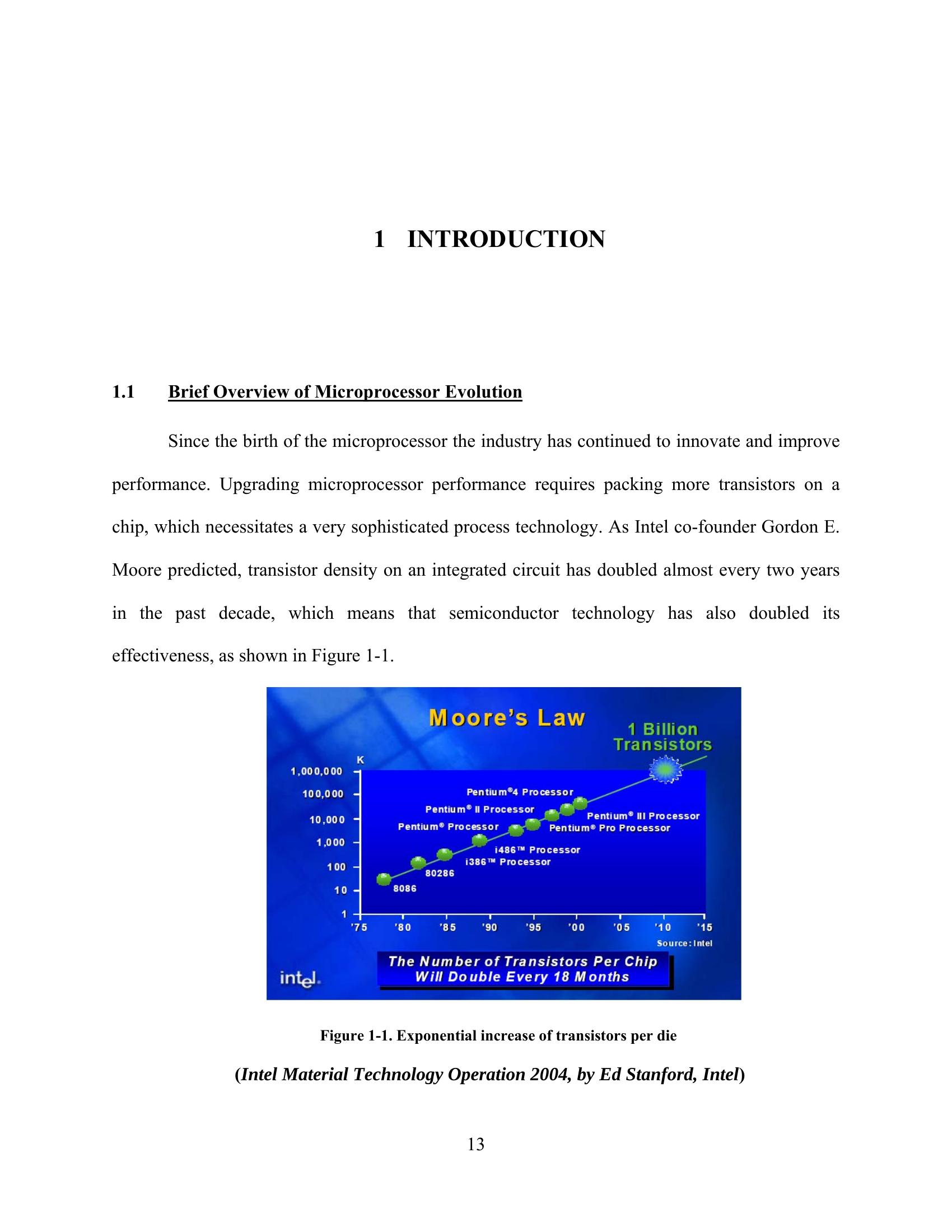

The microprocessor frequency of operation has also increased dramatically along with

the increase of device density. Load transition speeds have also increased as a result of high

frequencies. Billions of transistors operating in GHz scale frequencies result in tremendous

amount of power dissipation leading to very high overall and extremely high-localized spatial

thermal stress. As a consequence, there is an immediate need for techniques to manage power

and performance especially in systems that run multiple applications such as multi-core systems.

With the recent trend towards system-on-a-chip and multi-core systems, power management

techniques that were designed for single-core microprocessors must be improved and applied at

the chip-level to exploit the larger design space.

Figure 1-2. Current and voltage roadmap for present and future microprocessors

(Intel Material Technology Operation 2004, by Ed Stanford, Intel, [38])

14

1.2 Microprocessor Power Delivery and Load Characteristics

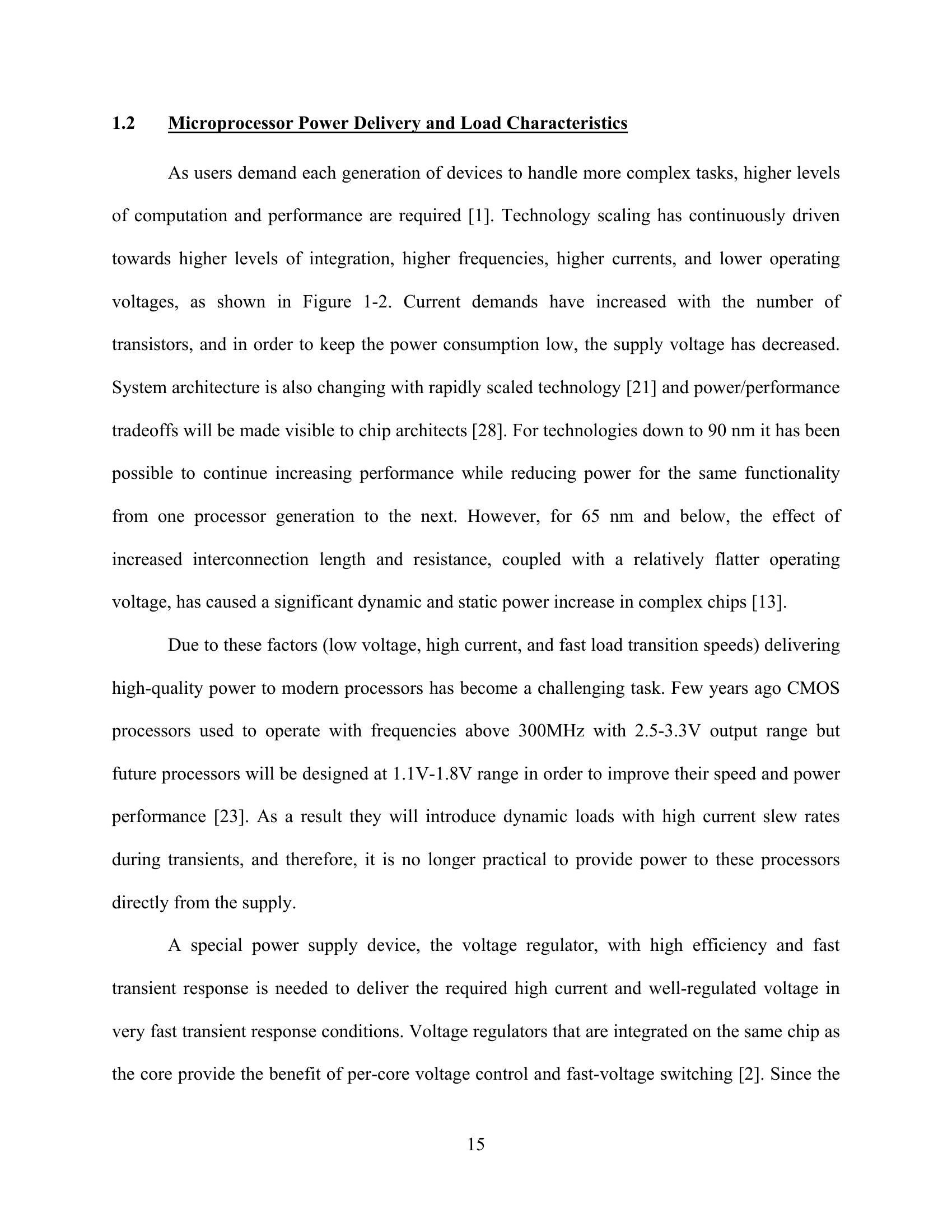

As users demand each generation of devices to handle more complex tasks, higher levels

of computation and performance are required [1]. Technology scaling has continuously driven

towards higher levels of integration, higher frequencies, higher currents, and lower operating

voltages, as shown in Figure 1-2. Current demands have increased with the number of

transistors, and in order to keep the power consumption low, the supply voltage has decreased.

System architecture is also changing with rapidly scaled technology [21] and power/performance

tradeoffs will be made visible to chip architects [28]. For technologies down to 90 nm it has been

possible to continue increasing performance while reducing power for the same functionality

from one processor generation to the next. However, for 65 nm and below, the effect of

increased interconnection length and resistance, coupled with a relatively flatter operating

voltage, has caused a significant dynamic and static power increase in complex chips [13].

Due to these factors (low voltage, high current, and fast load transition speeds) delivering

high-quality power to modern processors has become a challenging task. Few years ago CMOS

processors used to operate with frequencies above 300MHz with 2.5-3.3V output range but

future processors will be designed at 1.1V-1.8V range in order to improve their speed and power

performance [23]. As a result they will introduce dynamic loads with high current slew rates

during transients, and therefore, it is no longer practical to provide power to these processors

directly from the supply.

A special power supply device, the voltage regulator, with high efficiency and fast

transient response is needed to deliver the required high current and well-regulated voltage in

very fast transient response conditions. Voltage regulators that are integrated on the same chip as

the core provide the benefit of per-core voltage control and fast-voltage switching [2]. Since the

15

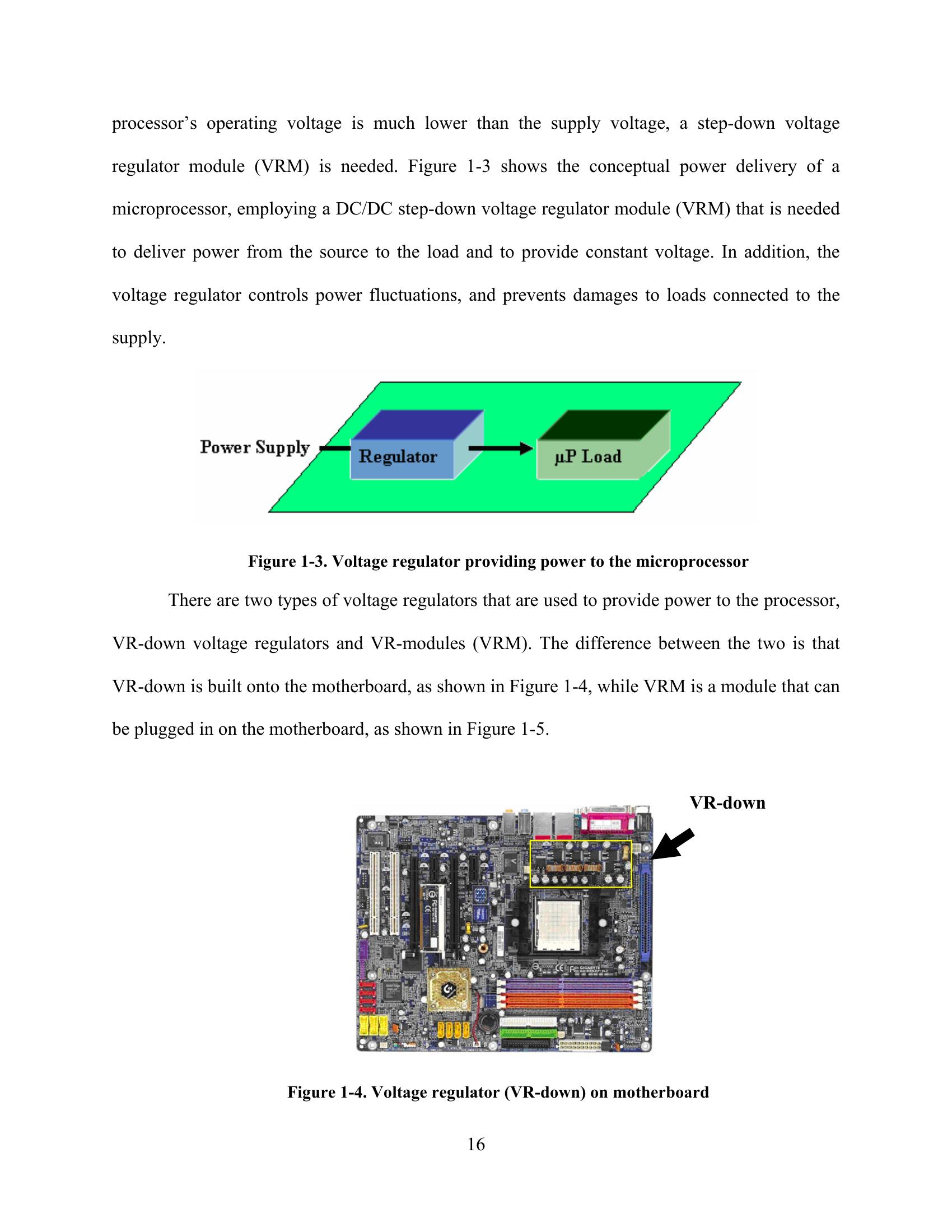

processor’s operating voltage is much lower than the supply voltage, a step-down voltage

regulator module (VRM) is needed. Figure 1-3 shows the conceptual power delivery of a

microprocessor, employing a DC/DC step-down voltage regulator module (VRM) that is needed

to deliver power from the source to the load and to provide constant voltage. In addition, the

voltage regulator controls power fluctuations, and prevents damages to loads connected to the

supply.

Figure 1-3. Voltage regulator providing power to the microprocessor

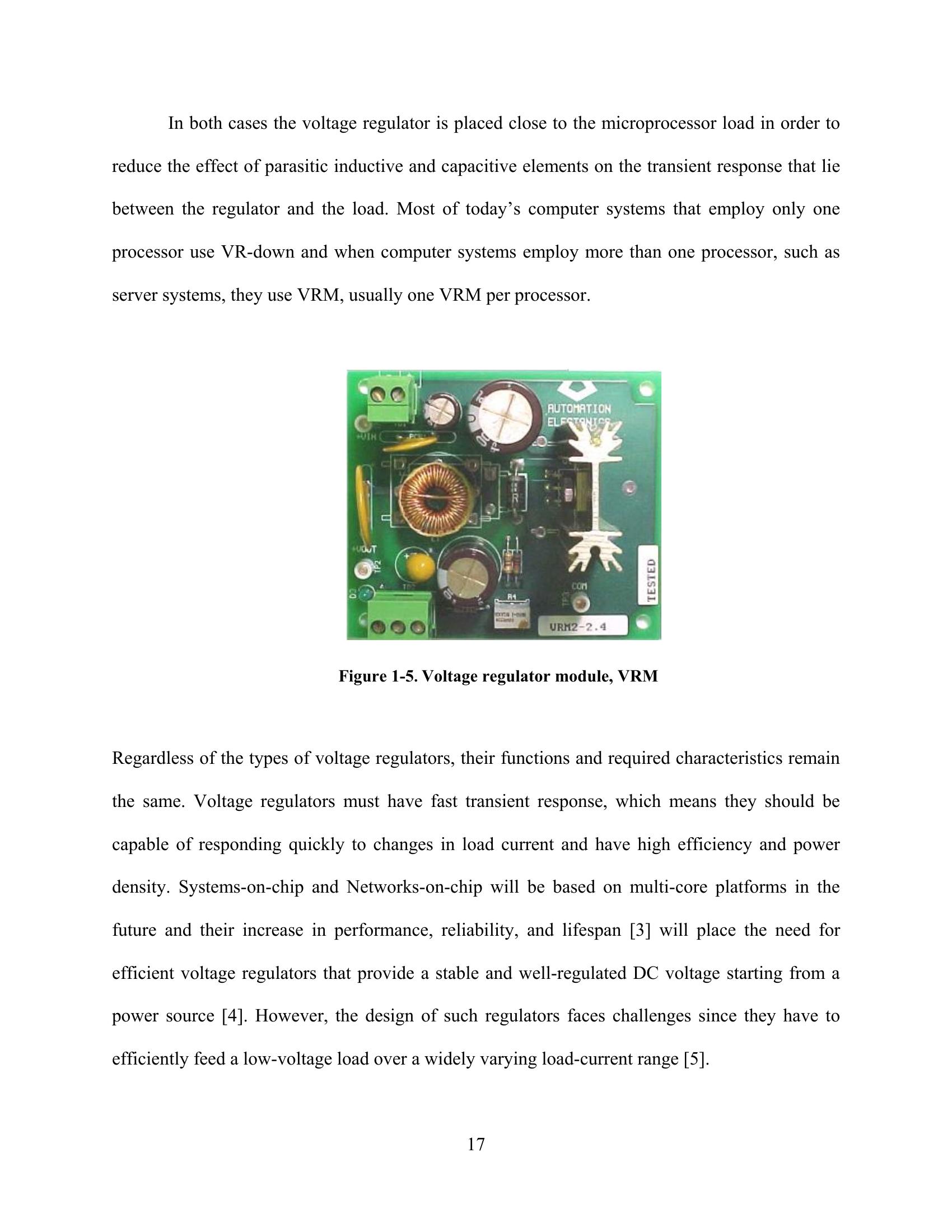

There are two types of voltage regulators that are used to provide power to the processor,

VR-down voltage regulators and VR-modules (VRM). The difference between the two is that

VR-down is built onto the motherboard, as shown in Figure 1-4, while VRM is a module that can

be plugged in on the motherboard, as shown in Figure 1-5.

VR-down

Figure 1-4. Voltage regulator (VR-down) on motherboard

16

In both cases the voltage regulator is placed close to the microprocessor load in order to

reduce the effect of parasitic inductive and capacitive elements on the transient response that lie

between the regulator and the load. Most of today’s computer systems that employ only one

processor use VR-down and when computer systems employ more than one processor, such as

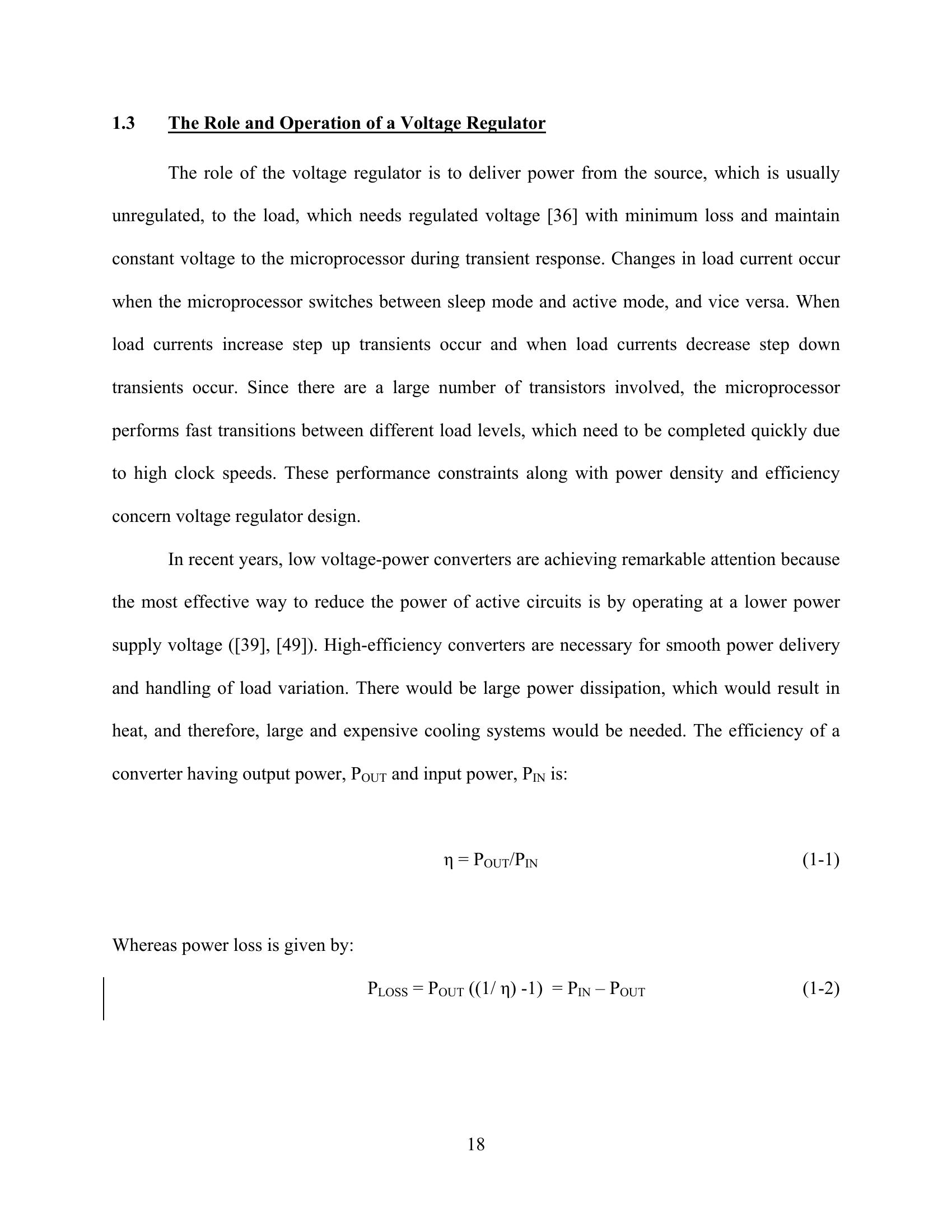

server systems, they use VRM, usually one VRM per processor.

Figure 1-5. Voltage regulator module, VRM

Regardless of the types of voltage regulators, their functions and required characteristics remain

the same. Voltage regulators must have fast transient response, which means they should be

capable of responding quickly to changes in load current and have high efficiency and power

density. Systems-on-chip and Networks-on-chip will be based on multi-core platforms in the

future and their increase in performance, reliability, and lifespan [3] will place the need for

efficient voltage regulators that provide a stable and well-regulated DC voltage starting from a

power source [4]. However, the design of such regulators faces challenges since they have to

efficiently feed a low-voltage load over a widely varying load-current range [5].

17

1.3 The Role and Operation of a Voltage Regulator

The role of the voltage regulator is to deliver power from the source, which is usually

unregulated, to the load, which needs regulated voltage [36] with minimum loss and maintain

constant voltage to the microprocessor during transient response. Changes in load current occur

when the microprocessor switches between sleep mode and active mode, and vice versa. When

load currents increase step up transients occur and when load currents decrease step down

transients occur. Since there are a large number of transistors involved, the microprocessor

performs fast transitions between different load levels, which need to be completed quickly due

to high clock speeds. These performance constraints along with power density and efficiency

concern voltage regulator design.

In recent years, low voltage-power converters are achieving remarkable attention because

the most effective way to reduce the power of active circuits is by operating at a lower power

supply voltage ([39], [49]). High-efficiency converters are necessary for smooth power delivery

and handling of load variation. There would be large power dissipation, which would result in

heat, and therefore, large and expensive cooling systems would be needed. The efficiency of a

converter having output power, P and input power, P is:

OUT IN

η = P /P (1-1)

OUT IN

Whereas power loss is given by:

P = P ((1/ η) -1) = P – P (1-2)

LOSS OUT IN OUT

18

This power loss is converted into heat, which must be removed from the converter. This leads to

a large and expensive cooling system, it causes the electronic elements within the converter to

operate at high temperature, and it reduces the system reliability. Certainly, at high output

powers, it may be impossible to sufficiently cool the converter elements using current

technology.

Efficiency is a good measure of the quality of a given converter technology. When very

little power is lost, the converter elements can be packaged with high density, leading to a

converter of small size and weight, and of low temperature rise. The question is how can we

build a converter circuit that changes the voltage, yet dissipates negligible power? The available

circuit elements that can be used to build such converter circuit are [51]:

• Resistive elements, capacitive elements, magnetic devices including inductors and

transformers, semiconductor devices operated in the linear mode (for example, as

class A or class B amplifiers)

• Semiconductor devices operated in the switched mode (such as in logic devices

where transistors operate in either saturation or cutoff).

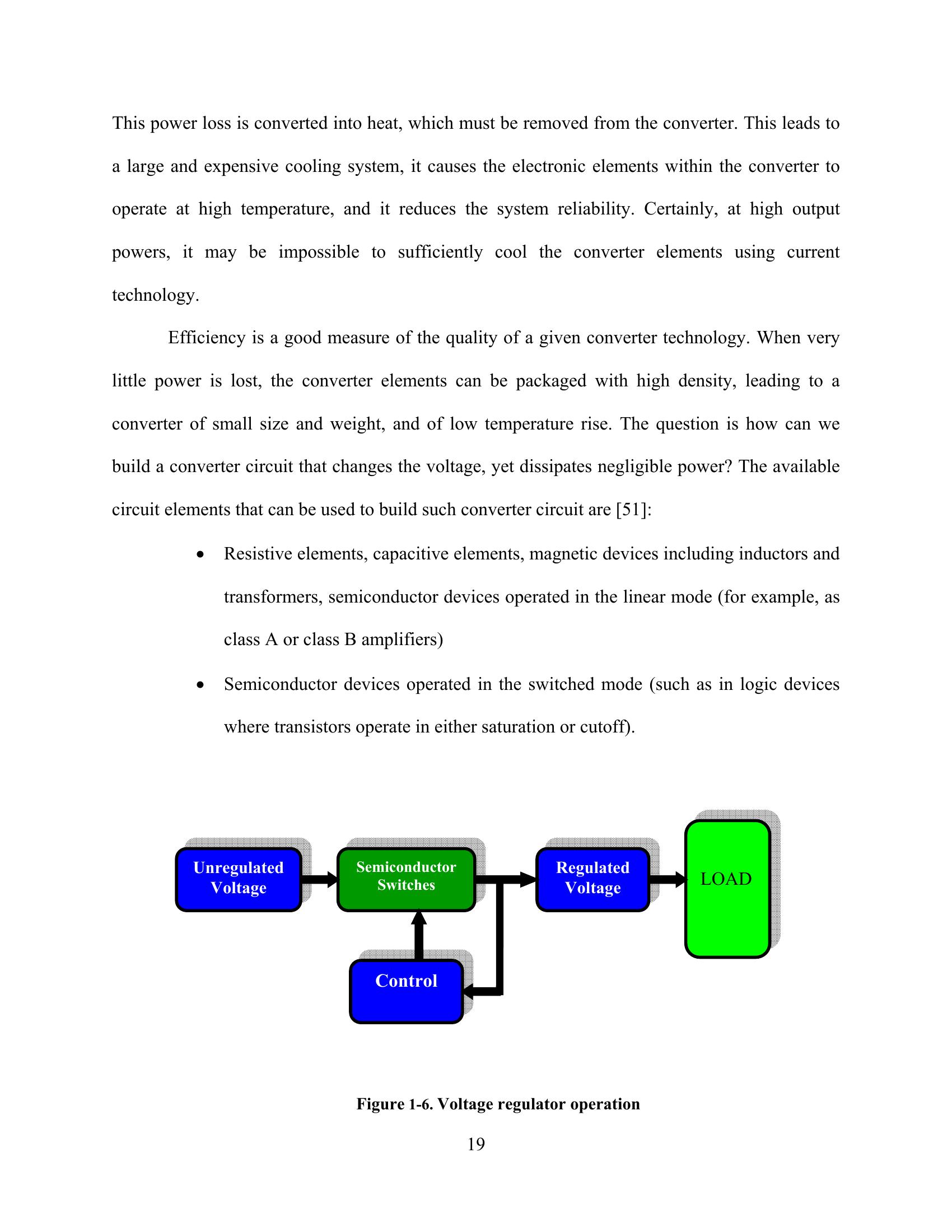

Unregulated Semiconductor Regulated

LOAD

Voltage Switches Voltage

Control

Figure 1-6. Voltage regulator operation

19

Figure 1-6 shows how the voltage regulator takes an unregulated voltage and through

semiconductor switches and control circuitry provides a regulated output voltage that is suitable

for load operation.

In conventional signal processing applications, where efficiency is not the primary

concern, inductors are usually avoided wherever possible, because of their large size and the

difficulty of incorporating them into integrated circuits. In contrast, capacitors and magnetic

devices are important elements of switching converters, because ideally they do not consume

power. It is the resistive element, as well as the linear-mode semiconductor device, that is

avoided [2]. Switched-mode semiconductor devices are also employed. When a semiconductor

device operates in the off state, its current is zero, and hence its power dissipation is zero. When

the semiconductor device operates in the on (saturated) state, its voltage drop is small, and hence

its power dissipation is also small. In either event, the power dissipated by the semiconductor

device is low. So capacitive and inductive elements, as well as switched-mode semiconductor

devices, are available for synthesis of high-efficiency converters.

1.4 Off-Chip VR Alernatives

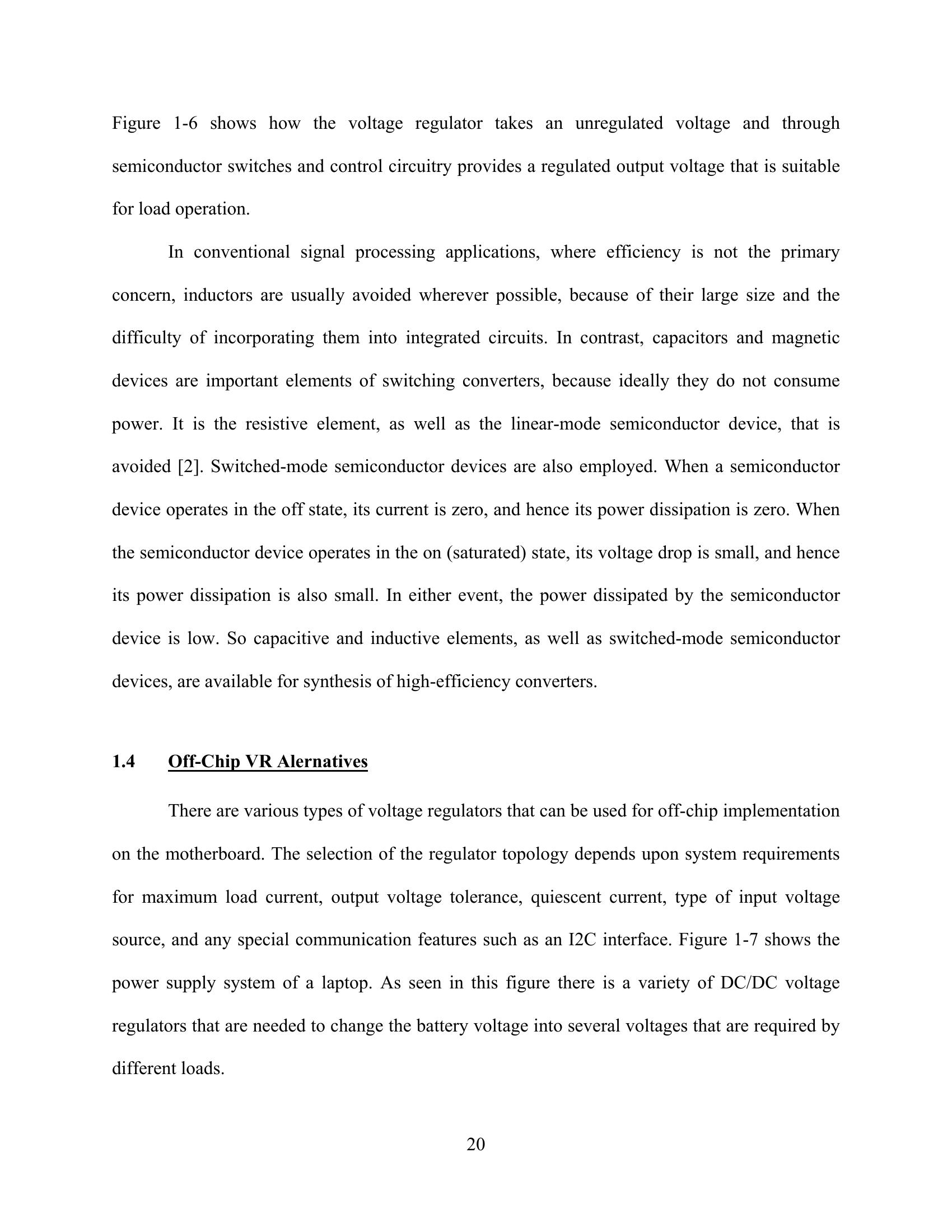

There are various types of voltage regulators that can be used for off-chip implementation

on the motherboard. The selection of the regulator topology depends upon system requirements

for maximum load current, output voltage tolerance, quiescent current, type of input voltage

source, and any special communication features such as an I2C interface. Figure 1-7 shows the

power supply system of a laptop. As seen in this figure there is a variety of DC/DC voltage

regulators that are needed to change the battery voltage into several voltages that are required by

different loads.

20

Display

Inverter

Backlighting

Buck Microprocessor

AC Charger

Boost Disk

Drive

Figure 1-7. Laptop power supply

In this scheme, the charger converts alternating current (AC) from the power line to

direct current (DC) to charge the battery. The inverter produces high voltage and high frequency

AC that is needed to drive lamps for backlighting. The boost converter is a step-up converter

which increases battery voltage to the level required by the disk drive. Finally, the buck

converter which is a step-down converter decreases battery voltage to produce low level DC

voltage that is needed by the microprocessor. Here, the microprocessor requires aggressive

power management to control various modes such as sleep mode and active mode in order to

reduce power consumption and save battery life.

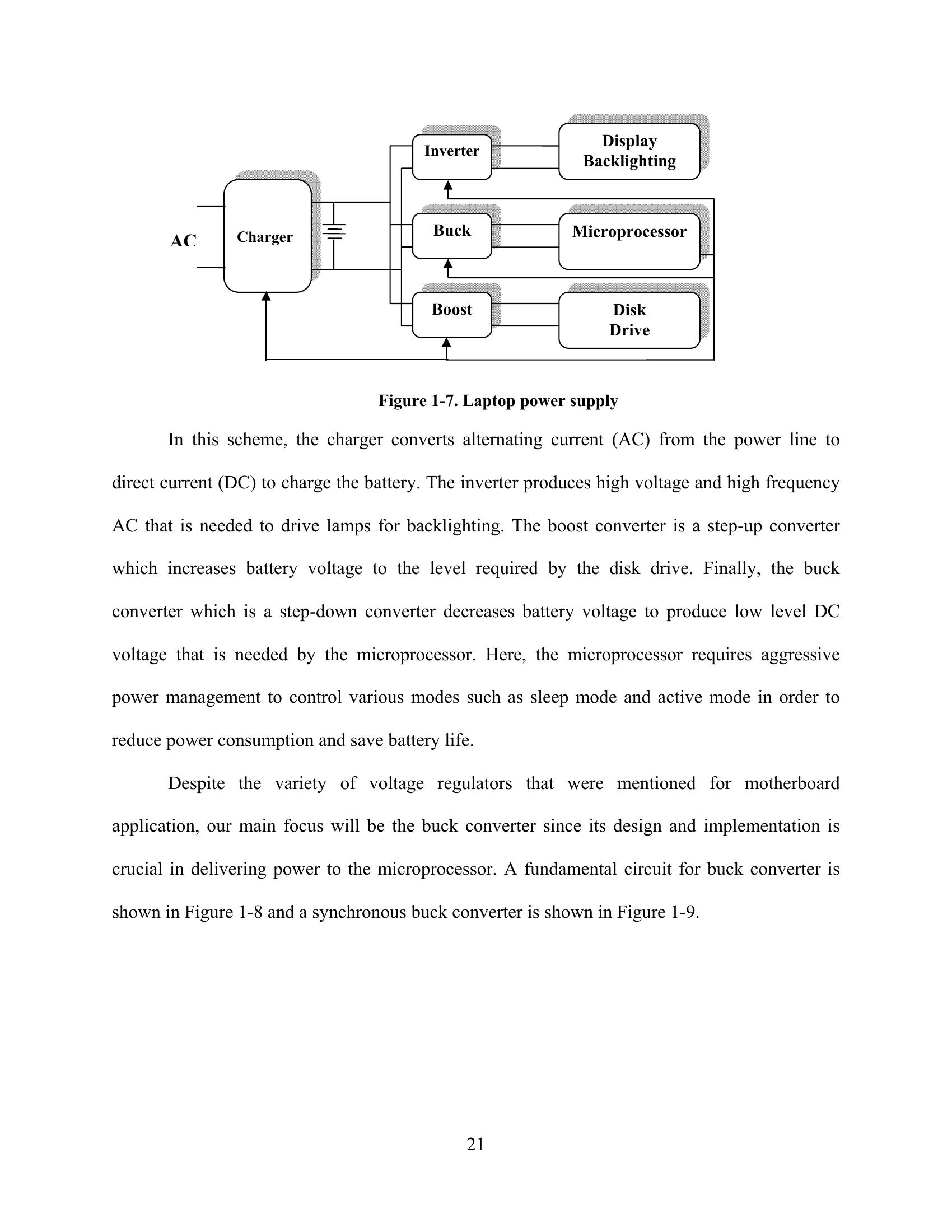

Despite the variety of voltage regulators that were mentioned for motherboard

application, our main focus will be the buck converter since its design and implementation is

crucial in delivering power to the microprocessor. A fundamental circuit for buck converter is

shown in Figure 1-8 and a synchronous buck converter is shown in Figure 1-9.

21

| None | |

| None |

Figure 1-8. Circuit of a conventional buck converter [23]

Figure 1-9. Circuit of a synchronous buck converter [33]

Low-voltage power supplies require a synchronous buck converter as oppose to the conventional

converter. Here, the diode is replaced by a MOSFET for better efficiency. The transistor channel

conducts current in the reverse direction and blocks negative voltage while conducting positive

current. The diode is the major source of loss and when it is replaced by MOSFET the

conduction loss decreases since the transistor operates as a synchronous rectifier. Other losses

include the series resistance of the battery, the on-resistance of the switching element, and the

resistances in the conductors, connectors and wiring [42, 43]. Switching loss and inductance loss

increase with frequency, which limits the operating range of the DC-DC converters to a few

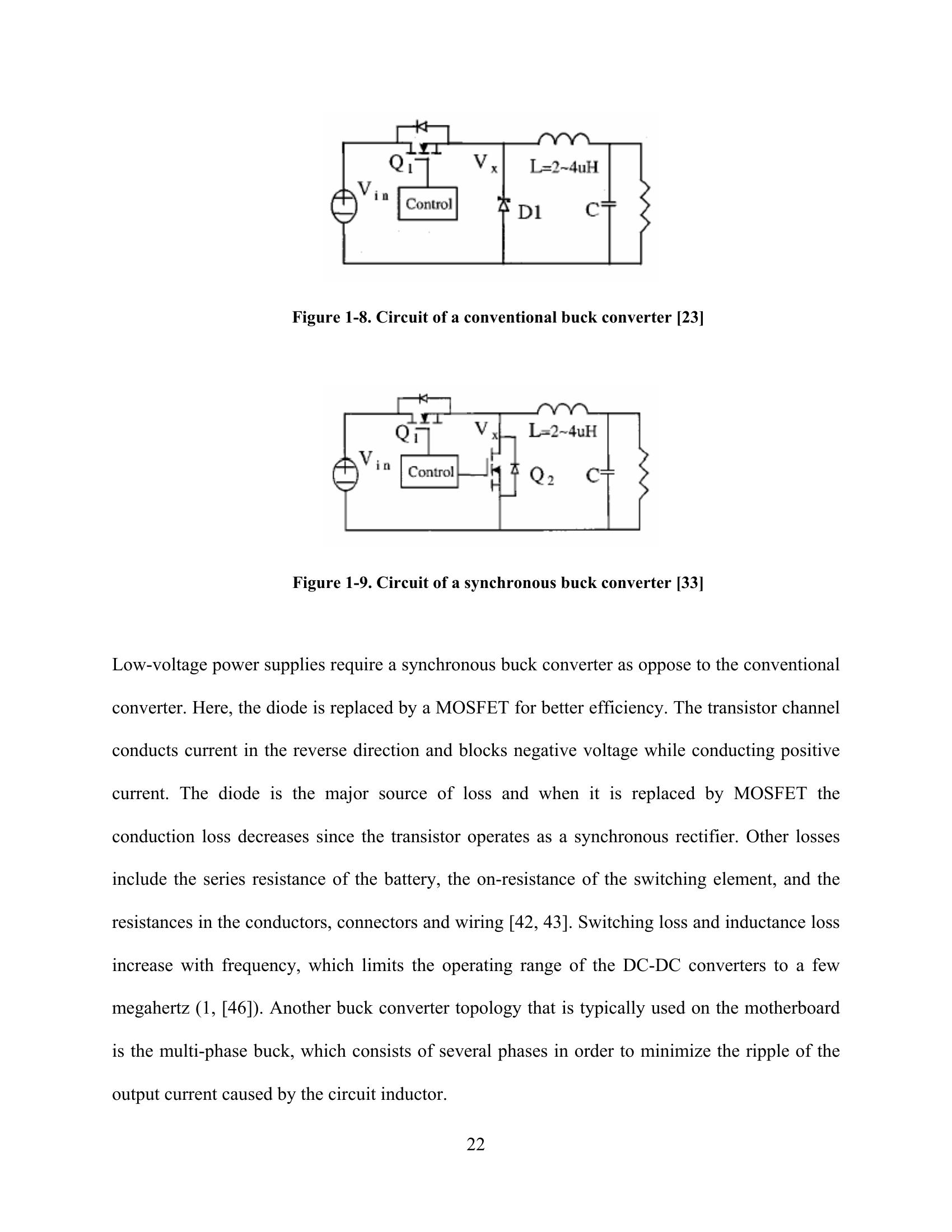

megahertz (1, [46]). Another buck converter topology that is typically used on the motherboard

is the multi-phase buck, which consists of several phases in order to minimize the ripple of the

output current caused by the circuit inductor.

22

Figure 1-10. Circuit of a multi-phase buck converter [1]

Figure 1-10 shows a typical synchronous multi-phase buck converter that employs

inductances with smaller values. Large inductors cause large current ripple at the output so the

multi-phase buck converter allows the cancellation of the current ripples at the output node thus

providing an output current with less ripple. Using smaller inductances also improves transient

response and power density. Another potential benefit of this converter topology is the even

distribution of thermal dissipation due to scattering of the branches. Therefore, this technique has

become very popular in the power electronics industry. Drawback of this technique is that using

smaller inductance reduces efficiency [44].

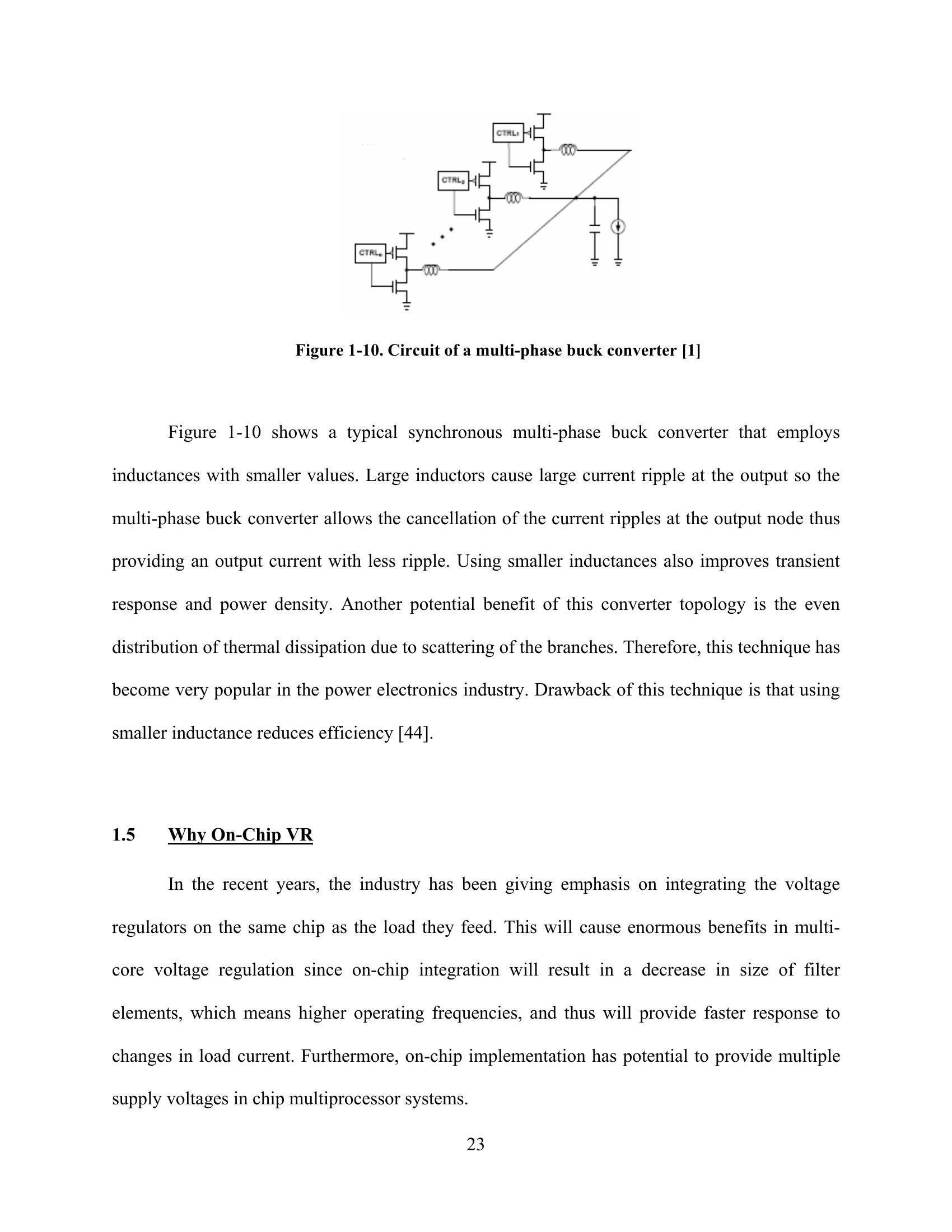

1.5 Why On-Chip VR

In the recent years, the industry has been giving emphasis on integrating the voltage

regulators on the same chip as the load they feed. This will cause enormous benefits in multi-

core voltage regulation since on-chip integration will result in a decrease in size of filter

elements, which means higher operating frequencies, and thus will provide faster response to

changes in load current. Furthermore, on-chip implementation has potential to provide multiple

supply voltages in chip multiprocessor systems.

23

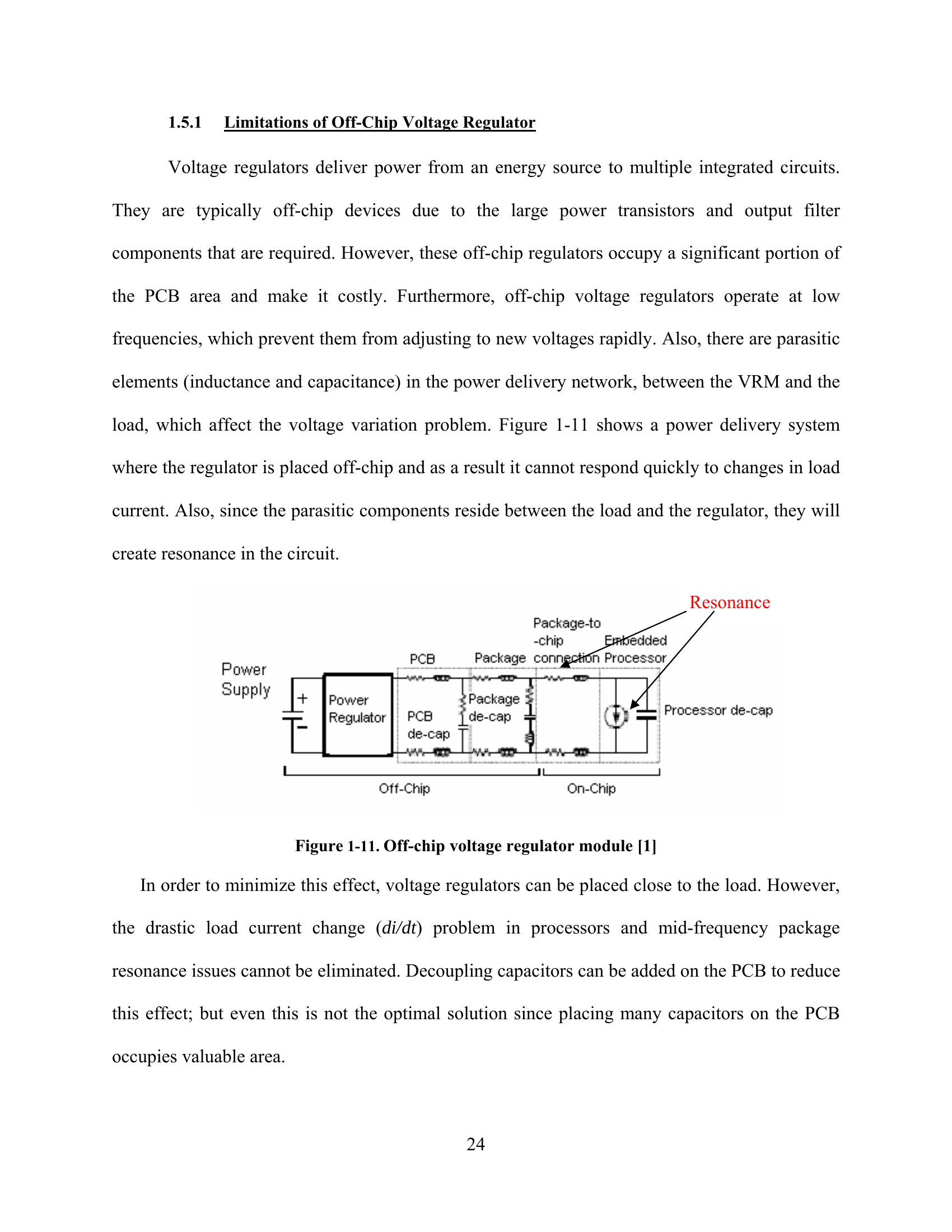

1.5.1 Limitations of Off-Chip Voltage Regulator

Voltage regulators deliver power from an energy source to multiple integrated circuits.

They are typically off-chip devices due to the large power transistors and output filter

components that are required. However, these off-chip regulators occupy a significant portion of

the PCB area and make it costly. Furthermore, off-chip voltage regulators operate at low

frequencies, which prevent them from adjusting to new voltages rapidly. Also, there are parasitic

elements (inductance and capacitance) in the power delivery network, between the VRM and the

load, which affect the voltage variation problem. Figure 1-11 shows a power delivery system

where the regulator is placed off-chip and as a result it cannot respond quickly to changes in load

current. Also, since the parasitic components reside between the load and the regulator, they will

create resonance in the circuit.

Resonance

Figure 1-11. Off-chip voltage regulator module [1]

In order to minimize this effect, voltage regulators can be placed close to the load. However,

the drastic load current change (di/dt) problem in processors and mid-frequency package

resonance issues cannot be eliminated. Decoupling capacitors can be added on the PCB to reduce

this effect; but even this is not the optimal solution since placing many capacitors on the PCB

occupies valuable area.

24

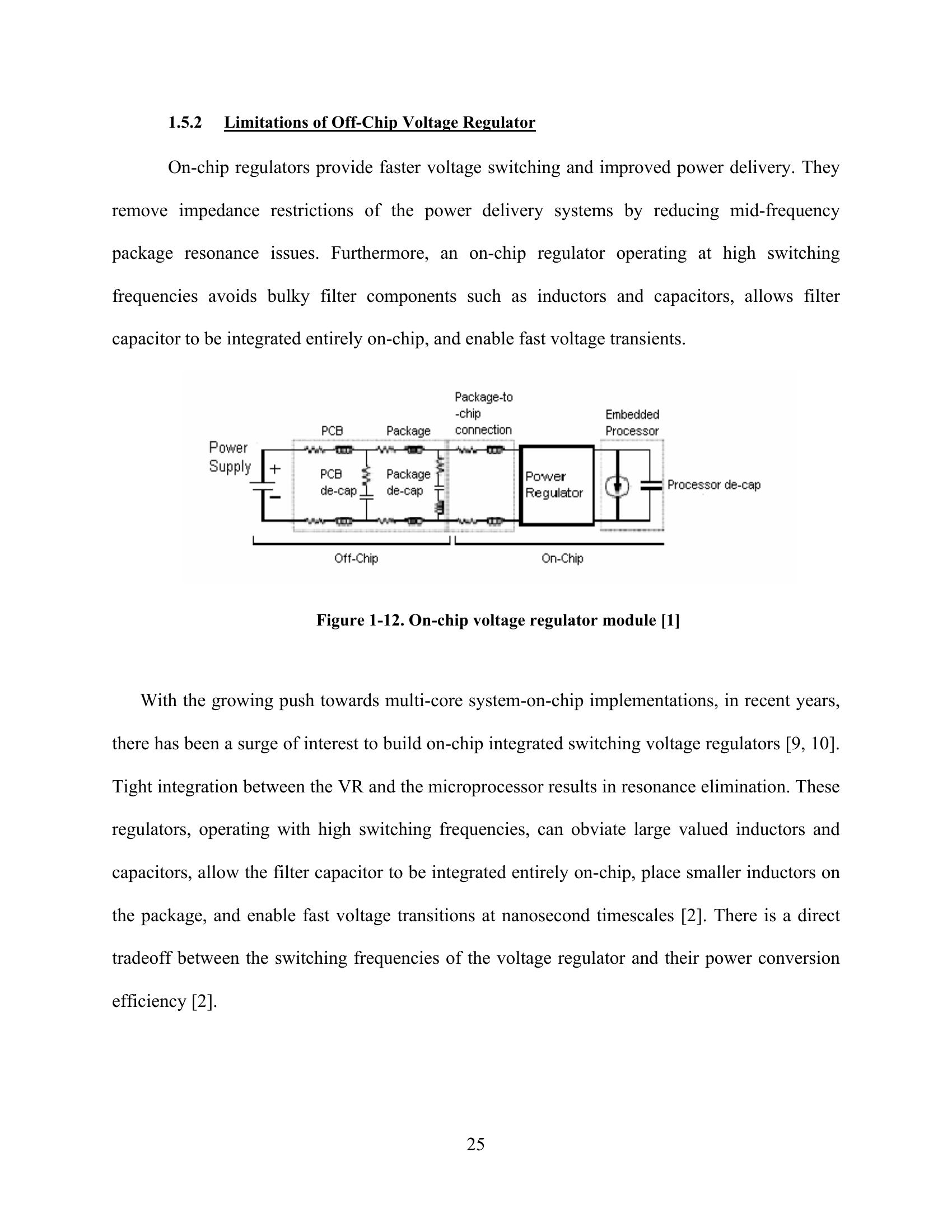

1.5.2 Limitations of Off-Chip Voltage Regulator

On-chip regulators provide faster voltage switching and improved power delivery. They

remove impedance restrictions of the power delivery systems by reducing mid-frequency

package resonance issues. Furthermore, an on-chip regulator operating at high switching

frequencies avoids bulky filter components such as inductors and capacitors, allows filter

capacitor to be integrated entirely on-chip, and enable fast voltage transients.

Figure 1-12. On-chip voltage regulator module [1]

With the growing push towards multi-core system-on-chip implementations, in recent years,

there has been a surge of interest to build on-chip integrated switching voltage regulators [9, 10].

Tight integration between the VR and the microprocessor results in resonance elimination. These

regulators, operating with high switching frequencies, can obviate large valued inductors and

capacitors, allow the filter capacitor to be integrated entirely on-chip, place smaller inductors on

the package, and enable fast voltage transitions at nanosecond timescales [2]. There is a direct

tradeoff between the switching frequencies of the voltage regulator and their power conversion

efficiency [2].

25

1.6 Thesis Outline

This dissertation consists of six chapters, which are organized as follows. Chapter 1 is the

background review of multiprocessor evolution and existing voltage regulator topologies that are

used both off-chip and on-chip. Motivation of this dissertation as well as various limitations and

benefits of present on- and off-chip regulator topologies are also discussed. Chapter 2 offers a

detailed discussion and survey of regulator topologies that have been used for on-chip

implementation, as well as it discusses their benefits and drawbacks. Chapter 3 includes on-chip

regulator options for integrating a hot swap controller on-chip along with a switching regulator to

control and protect the core from seeing any droops in the circuit. Chapter 4 is the two-stage tree

design technique that is proposed to deliver power to various function blocks in a system-on-

Chip. Simulations and analysis are performed to show that this technique provides high

efficiency and is suitable for system-on-chip implementation. Chapter 5 includes a proposal for

system-on-chip and multi-core systems and why the proposed hybrid technique is effective in

these environments, detailed discussion of our future work is also discussed. Finally Chapter 6

concludes the dissertation.

26

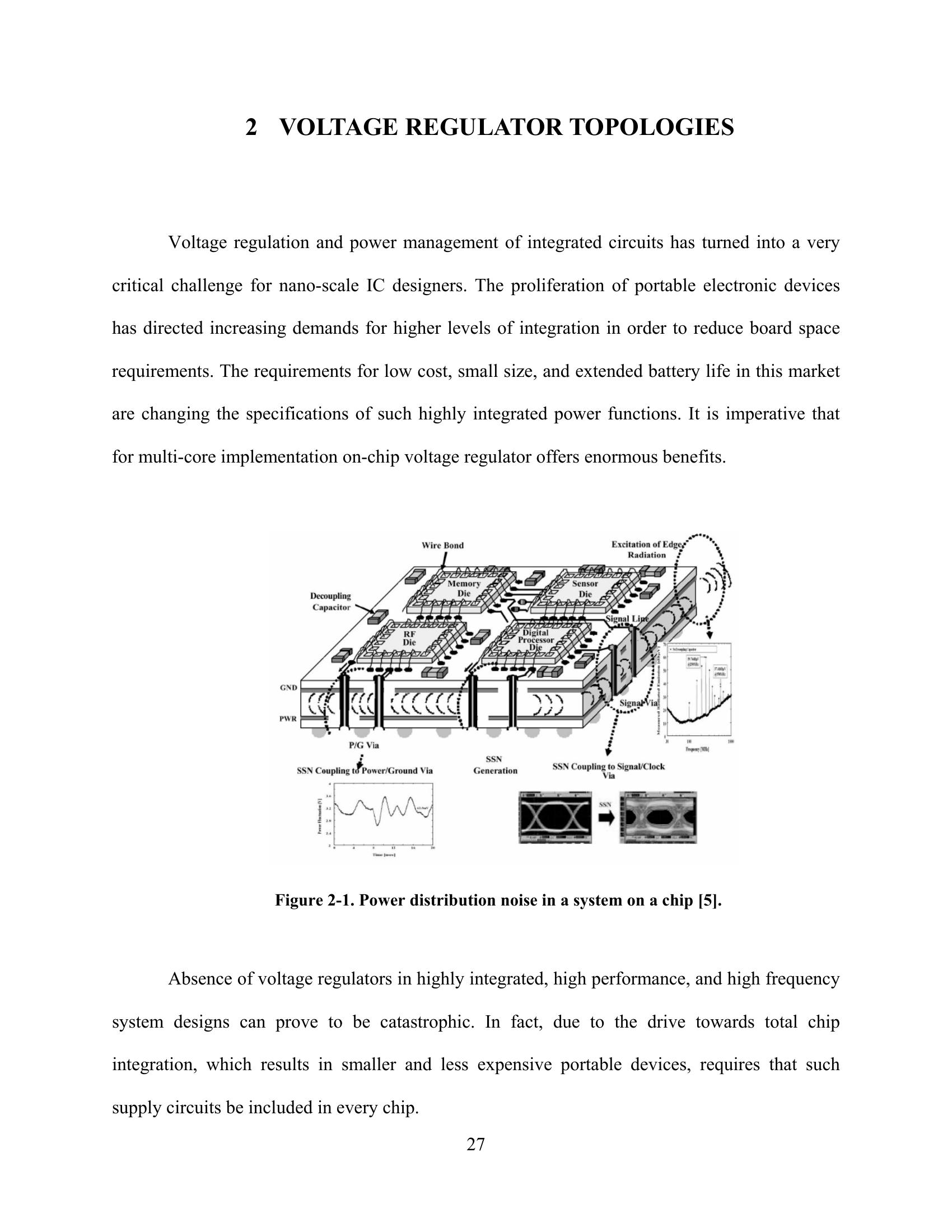

2 VOLTAGE REGULATOR TOPOLOGIES

Voltage regulation and power management of integrated circuits has turned into a very

critical challenge for nano-scale IC designers. The proliferation of portable electronic devices

has directed increasing demands for higher levels of integration in order to reduce board space

requirements. The requirements for low cost, small size, and extended battery life in this market

are changing the specifications of such highly integrated power functions. It is imperative that

for multi-core implementation on-chip voltage regulator offers enormous benefits.

Figure 2-1. Power distribution noise in a system on a chip [5].

Absence of voltage regulators in highly integrated, high performance, and high frequency

system designs can prove to be catastrophic. In fact, due to the drive towards total chip

integration, which results in smaller and less expensive portable devices, requires that such

supply circuits be included in every chip.

27

2.1 Complete Survey of all On-Chip VRM Topologies

Key to the design of power efficient ICs is performing high-efficiency DC/DC

conversion. In general, DC/DC converters are placed off-chip, where one regulator resides

between the source and each load and this is called star configuration [25]. This regulator

delivers current with the appropriate voltage levels to different loads in the circuit. ITRS predicts

an increase in the power consumption of microprocessors for future applications. The power

delivery network (PDN) provides the power supply to the processors and when it is not designed

properly it may be a major source of noise in the circuit, especially in high-speed electronic

systems.

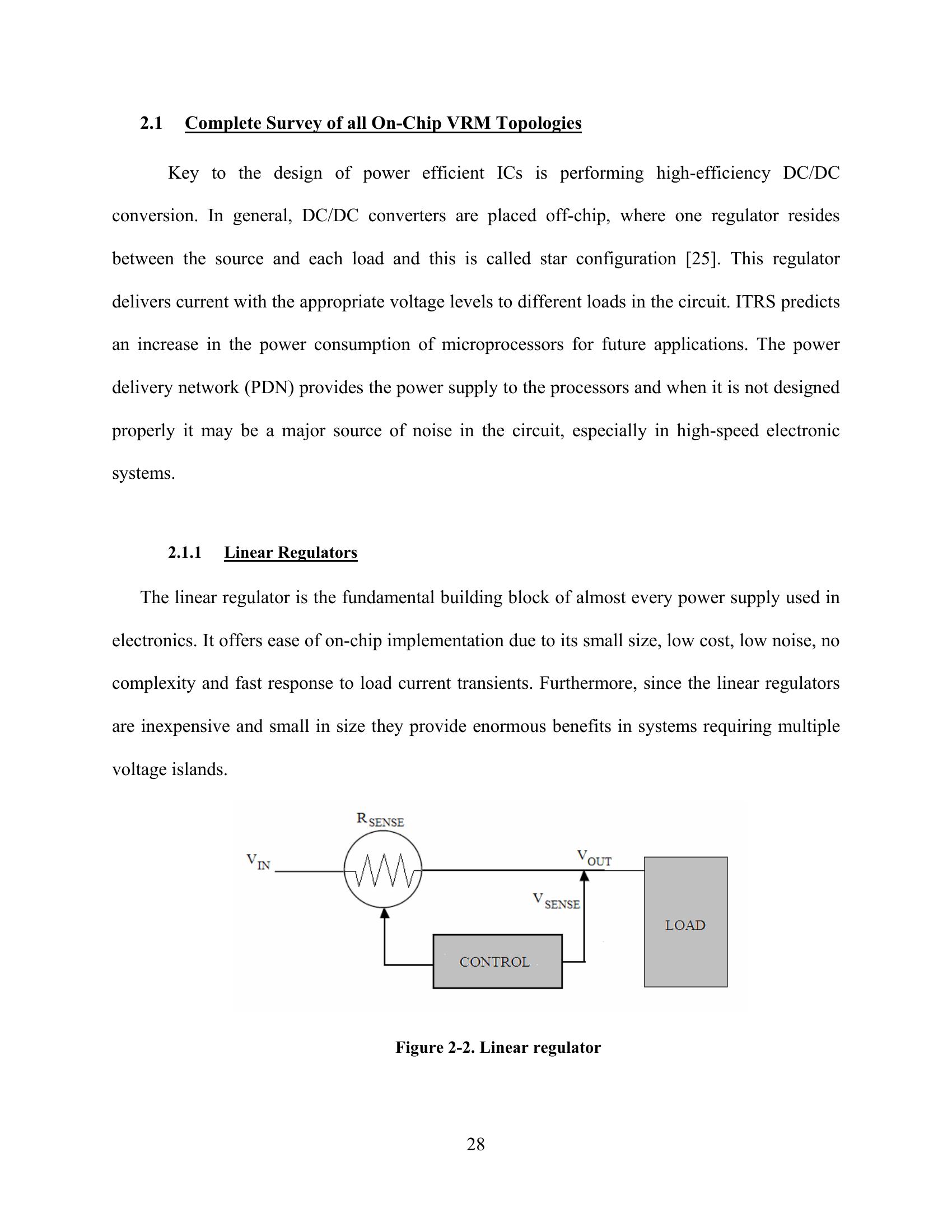

2.1.1 Linear Regulators

The linear regulator is the fundamental building block of almost every power supply used in

electronics. It offers ease of on-chip implementation due to its small size, low cost, low noise, no

complexity and fast response to load current transients. Furthermore, since the linear regulators

are inexpensive and small in size they provide enormous benefits in systems requiring multiple

voltage islands.

Figure 2-2. Linear regulator

28

Typical linear regulator is shown in Figure 2-2. The low noise characteristics and smaller size

and complexity also makes them potential candidates in systems where the difference between

the input and output voltages is small. This topology is especially preferred in low power

applications due to their low quiescent currents.

Referring to Figure 2-2, the linear regulator operates using a MOSFET acting as a sense

resistor in order to force a fixed voltage at the output. The role of the control circuit is to monitor

the output voltage and adjust the current through the sense resistor so the output voltage is held

at the desired value. The most efficient form of a linear regulator is the low dropout (LDO) linear

regulator. The dropout voltage refers to the minimum voltage drop required across the regulator

to maintain output voltage regulation. The lower the dropout voltage is, the higher its power

efficiency is since there is maximum power delivered to the load, which is given by:

P = (V V )*I (1-3)

IN- dropout load

Power extracted from the input source is:

P = V *(I + I ) (1-4)

IN load quiescent

P = (V -V )*I (1-5)

OUT IN load

Iquiesecent is the quiescent current in the internal LDO circuitry. To have a high efficiency LDO

regulator the dropout voltage and the quiescent current must be minimized and also, the voltage

29

difference between input and output must be minimized since the internal power dissipation of

LDO regulators, equation (1-5) accounts for the loss of power efficiency.

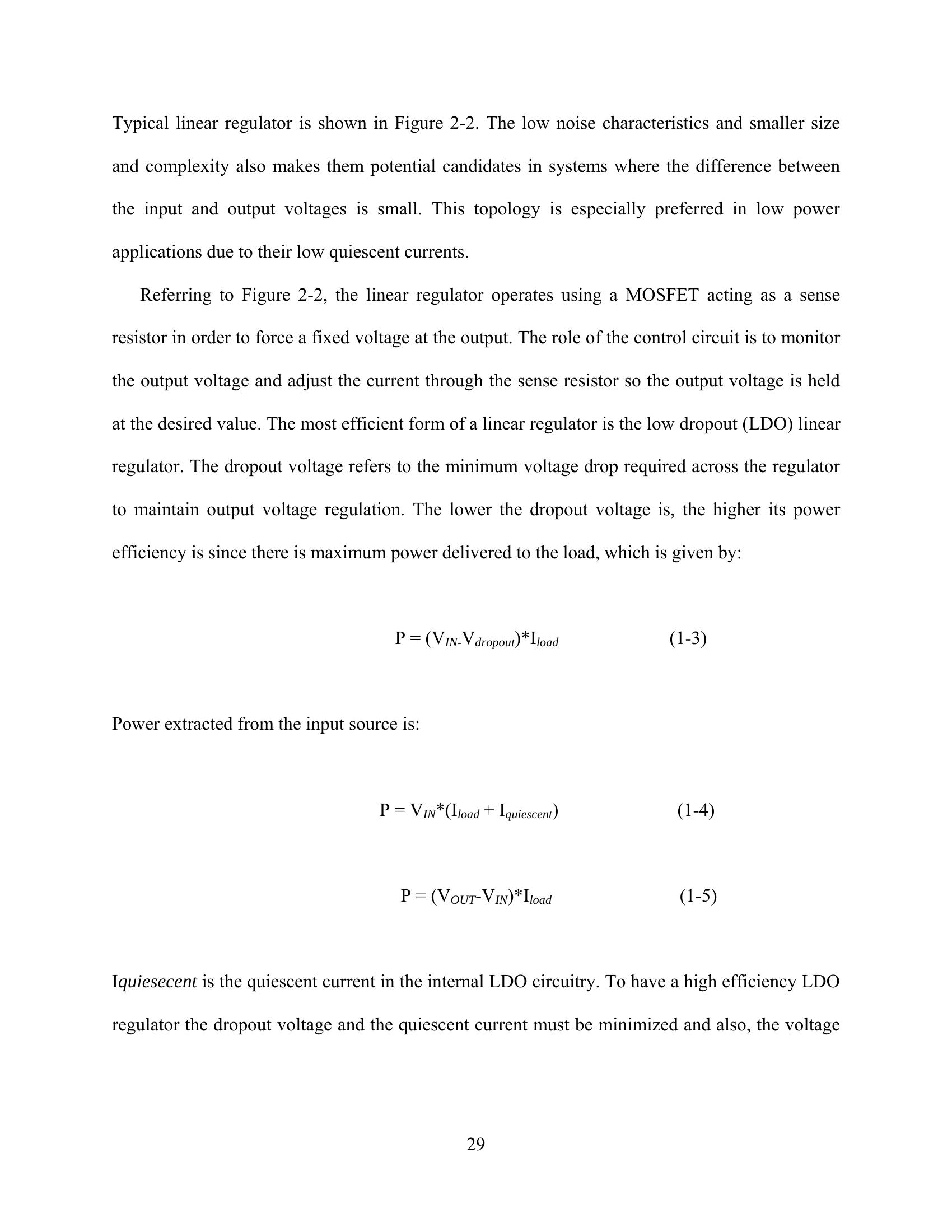

2.1.2 Switching Regulators

Switching regulators are generally mixed-mode circuits that feed back an analog error

signal and digitally gate it to provide bursts of current at the output [29]. They provide good

power conversion efficiency due to the presence of inductor, which is a low-loss energy transfer

device. This regulator topology is less sensitive to the V /V ratio and can regulate a wide

OUT IN

range of output voltage levels with better efficiency. A typical switching regulator topology is

shown in Figure 2-3.

Figure 2-3. Switching regulator

The switching regulator circuit requires a controller with an oscillator, pass elements,

inductor, capacitor, and diodes [29]. The worst-case response time of a dc-dc converter depends

on the oscillating frequency of the controller (20 – 200 kHz) and circuit delay and as a result, the

response time is 6-8 µs, whereas linear regulator is faster and requires 1-2 µs [29]. The output

voltage of a switching regulator is noisy due to the presence of the inductor, which causes large

current ripple at the output. The high noise present is also a consequence of the rectified inductor

30

voltage behavior of the output of these converters. Also, the noise problem is aggravated by

on/off sleep mode transitions.

2.2 Other On-Chip-Friendly VR Topologies

There are other topologies that may be used for on-chip implementation however their

use is limited by system requirements and specifications.

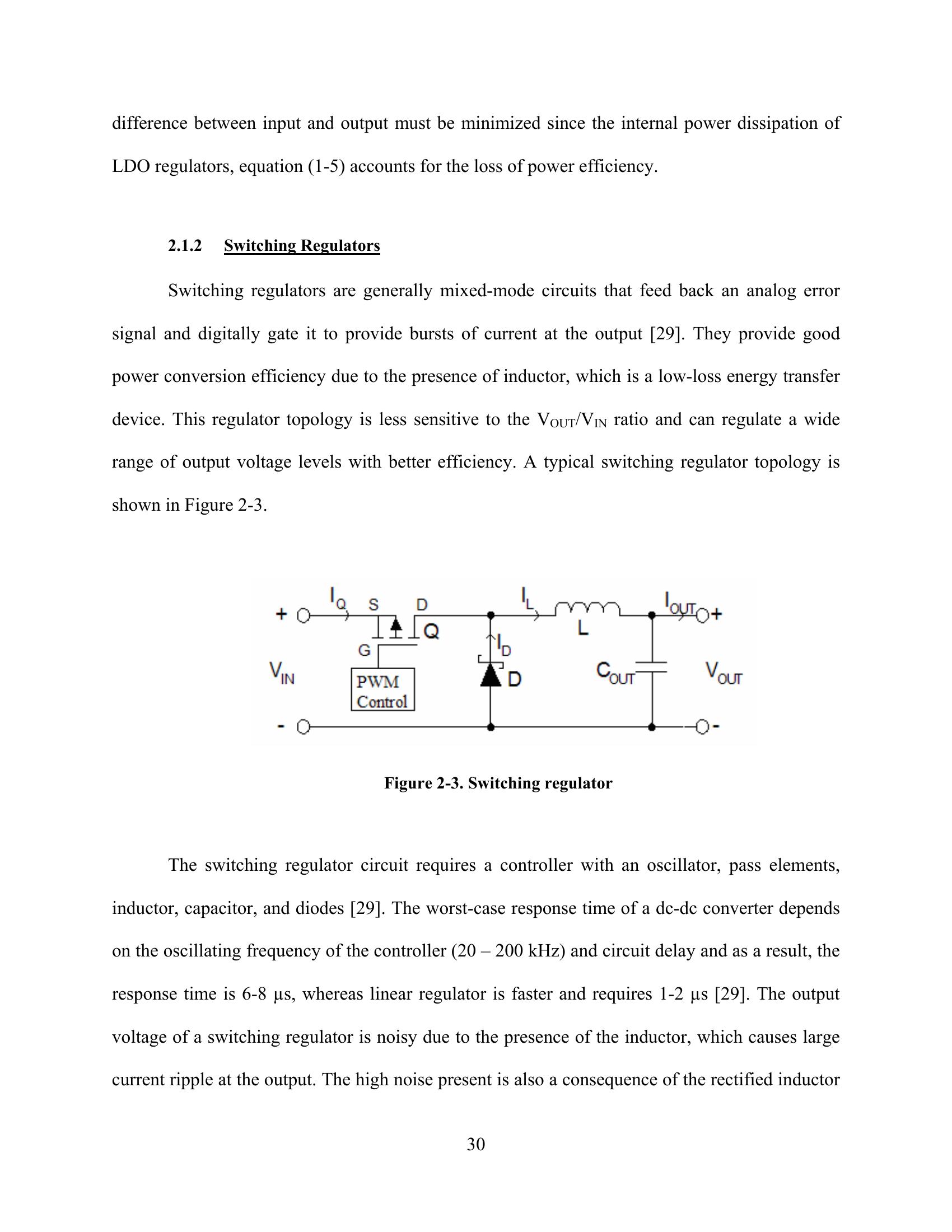

2.2.1 Switched Capacitor Circuits (Charge Pumps)

This type of DC/DC converters consist of switches and energy transfer capacitors in the

power stage as shown in Figure 2-4.

Figure 2-4. Switched capacitor regulator [14]

The switches are turned on and off so that the converter cycles through a number of

switched networks. This topology is easy to implement however, it has several drawbacks such

as pulsating input current, weak regulation capability due to V dependence from V , and the

OUT IN

voltage conversion is predetermined by the circuit structure.

31

2.2.2 MEMS Approach (DC/DC Converters with MEMS Inductors)

MEMS technology provides the integration of passive elements on-chip. These types of

DC/DC converters use micro-machined inductors. However, major drawback of this technique is

process compatibility with fabrication processes. It is very difficult to interface these types of

DC/DC converters on-chip with CMOS or BJT devices.

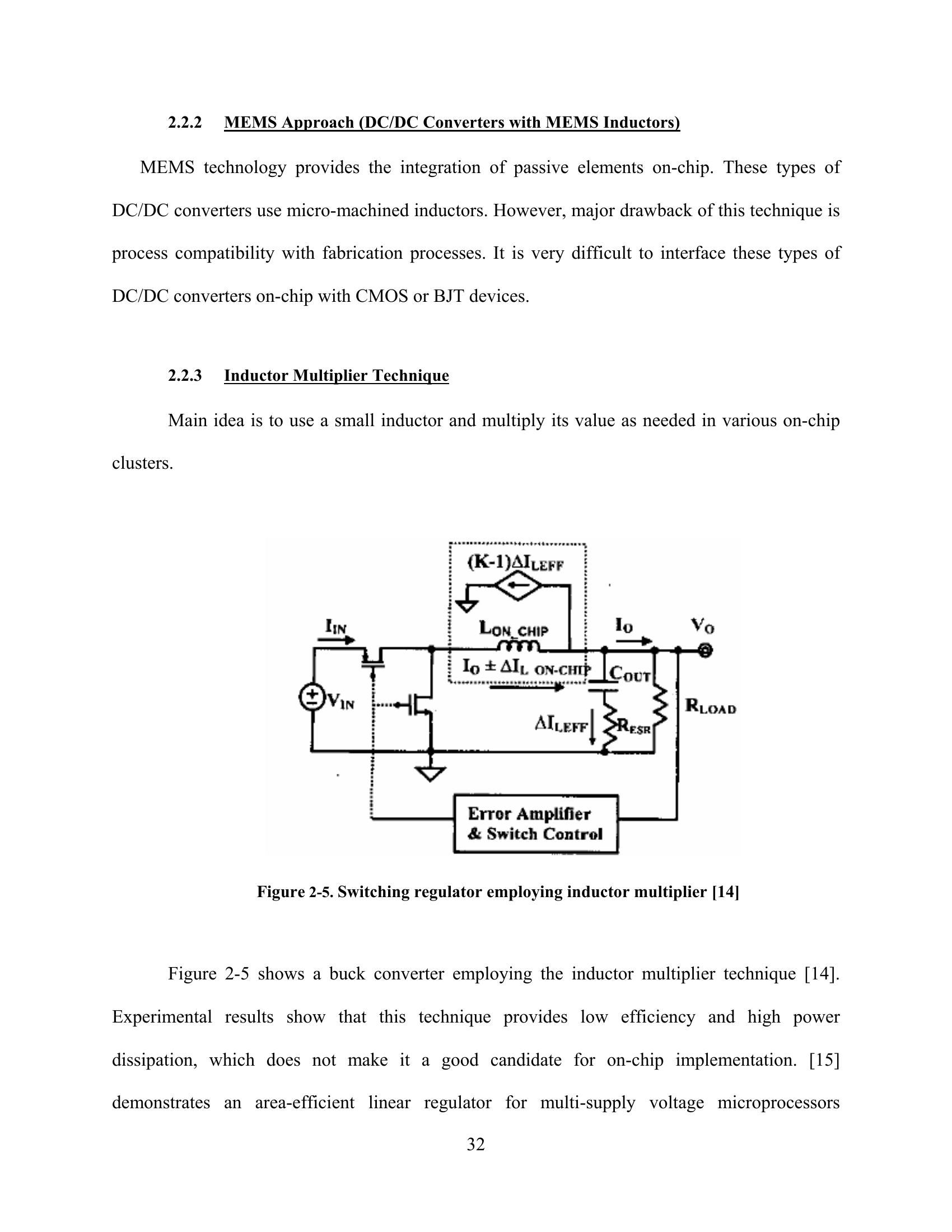

2.2.3 Inductor Multiplier Technique

Main idea is to use a small inductor and multiply its value as needed in various on-chip

clusters.

Figure 2-5. Switching regulator employing inductor multiplier [14]

Figure 2-5 shows a buck converter employing the inductor multiplier technique [14].

Experimental results show that this technique provides low efficiency and high power

dissipation, which does not make it a good candidate for on-chip implementation. [15]

demonstrates an area-efficient linear regulator for multi-supply voltage microprocessors

32

implemented in a 90 nm CMOS technology. This approach is good in terms of achieving high

current efficiency of 94%, however, it only provides 74% power efficiency for a 1.2V input and

0.9V output. Efficiency in the case of linear regulators is sensitive to V /V ratio. [16] also

OUT IN

provides an on-chip linear regulator topology that exhibits 96.5% current efficiency by

employing a flexible control technique of output current (FCOC). However, despite the high

current efficiency, power efficiency is relatively low for a 5V input and 3V output. It is about

60% due to the V /V dependency. An on-chip, two-stage approach consisting of a switched

OUT IN

capacitor regulator for high-voltage conversion and a linear regulator for low voltage conversion

was demonstrated in [50] however, this approach provides low efficiency.

2.3 Relative Merits/Demerits of Each Option

The integration of voltage regulators on the same chip that needs to be supplied poses

new challenges on process technology. This means that these regulators need to be available in

the same process technology as the application. It is very difficult to accomplish this task while

maintaining high efficiency and system performance. Both preferred topologies, linear and

switching, for on-chip implementation pose significant demerits in this concern.

Starting with the linear regulator, its dependency on the V /V ratio has negative

OUT IN

impact on the efficiency. If the value of the output voltage, V , is close to the value of the

OUT

input voltage, V , such as V /V = 1.0V/1.1V = 90% efficiency, we get good efficiency.

IN OUT IN

However, if the output voltage is much lower than the input voltage, such as V /V = 5V/10V

OUT IN

= 50% efficiency, we get poor efficiency since we have to drop 5V across the regulator. If our

output current would be say 10A then power dissipation would be 10A*5V = 50W which cannot

33

be ignored when it comes to on-chip implementation. It requires heat sinks, which may increase

area and cost.

Next in line, switching regulators, also exhibit serious concerns when it comes to on-chip

implementation. Major drawback of this topology is the large size of the inductor and capacitor

that occupy large printed circuit board (PCB) area. So, for off-chip implementation these types of

regulators are good in terms of providing high-conversion efficiency, but they occupy valuable

PCB space. For on-chip implementation, the size of the inductor and capacitor is reduced since

the regulator operates at high frequencies. However, this results in efficiency degradation since

reducing the on-chip filter capacitor limits the total amount of instantaneous charge available to

the load thus causing voltage fluctuations [27]. Another drawback of on-chip switching

regulators is their lack of providing clean output voltage due to the presence of the inductor.

Ripple voltage needs to be low in order not to effect the operation of the circuit the regulator is

supplying to. The requirements for high efficiency and high accuracy make the size of the

inductor prohibitively large for SOC solutions, where the inductor is embedded in the chip.

2.4 On-Chip VRM Issues

Before unveiling the next two chapters that discuss proposed approaches for

microprocessor and system-on-a-chip power delivery and management by integrating the

regulator on the same chip as the application, we should point out the requirements and issues

that concern their on-chip implementation. On-chip implementation requirements are efficient,

small, inexpensive, and simple regulator topologies that besides providing constant and well-

regulated voltage should also be capable of allowing the creation of multiple voltage islands on-

34

chip. This is important given the technology trend towards system-on-chip and chip

multiprocessors. Some of the challenges include:

• Efficiency degradation due to size reduction of filter components and high switching

frequencies.

• Smaller capacitor provides less charge to the load, which becomes vulnerable to large

di/dt events that cause voltage fluctuations.

• In order to reduce fluctuations, decoupling capacitors are used but with the overhead

of increasing chip area.

• On-chip regulator uses the filter capacitor for both decoupling and filtering, which

causes large voltage droops since large load current steps rapidly drain out the limited

charge stored on the capacitor.

• Circuit droops are assisted by filter component size reduction.

• Inductance issues. A decrease in inductance size results not only in faster switching

and higher inductor ripple current, but in a more noticeable parasitic inductance in the

circuit as well.

• Inductor fabrication challenges.

35

3 ON-CHIP VRM FOR SINGLE AND DUAL CORE SYSTEMS

International Technology Roadmap for Semiconductors, ITRS, [11] as well as most other

studies and roadmaps have specified that in all future micro- and nano-electronic circuits and

systems power management and distribution will become the most serious design challenge.

Power consumption has a critical impact on IC performance and therefore its management is

important. Ineffective power management causes lower chip performance, increases area and

makes the design nonfunctional.

Figure 3-1. Intel dual core processor, from Intel website

On-chip voltage regulation offers enormous benefits for embedded and portable electronic

systems, which are in high public demand. They provide fast voltage switching and improved

power delivery. However, their design and implementation has become a critical design

challenge in today’s computer microprocessor technology. This chapter gives detailed

simulations and analysis on how to handle challenges coming from on-chip voltage regulator

implementation on single and dual core systems.

36

3.1 Single-Core Voltage Regulation

Voltage regulators are found in nearly all computing systems and are essential for

delivering power from an energy source to multiple integrated circuits at their respective, desired

fixed or time-varying voltage levels [2]. Every electronic system is designed to operate at some

nominal supply voltage. The role of the regulator in these systems is to provide this constant

voltage, control power fluctuations, and prevent damage to loads connected to the supply. The

selection of the IC voltage regulator depends upon system requirements for maximum load

current, output voltage tolerance, quiescent current, type of input voltage source, and any special

communication features such as an I2C interface. Voltage regulators are usually off-chip devices,

however, they tend to occupy large PCB area and provide slow response to changes in load

current. Recently, their on-chip implementation has been proposed.

Although there are a variety of voltage regulator topologies to choose from, the most

commonly used for on-chip implementation are linear and switching regulators. Linear

regulators offer good response to load current transients, ease of on-chip integration, they have

relatively small size, and they are less expensive [2]. Linear regulator designs provide a clean

output with very little noise, therefore they are more suitable to use in designs that require low

output noise and fast input-output reaction, since they provide good response to changes in load

current. Drawback of linear regulators is their efficiency degradation with the V /V ratio, as

OUT IN

well as their inability to step up voltage.

On the other hand, switching regulators offer higher power conversion efficiency due to

their low-loss external inductor and increased design flexibility. The inductor allows the

regulator to transfer energy from input to output with no loss and it filters the output from

switching signals. Furthermore, switching regulators generate multiple output voltages from a

37

single input voltage and operate as a switch where its duty cycle determines how much charge is

transferred to the load [1]. Different than linear regulators, some types of switching regulators,

such as boost regulators, can provide outputs that are higher than the input. Conventional

switching regulators operate at relatively low switching frequencies and utilize bulky filter

components such as inductors and capacitors [7, 8]. Hence, voltage regulator modules typically

are separate, board-level components, with slow voltage adjustment capabilities [2].

With the growing push towards total chip integration, in recent years, there has been a

surge of interest to build on-chip integrated switching voltage regulators [9, 10]. These

regulators, operating with high switching frequencies, can obviate large valued inductors and

capacitors, allow the filter capacitor to be integrated entirely on-chip, place smaller inductors on

the package, and enable fast voltage transitions at nanosecond timescales [2]. There is a direct

tradeoff between the switching frequencies of the voltage regulator and their power conversion

efficiency [2]. Despite the benefits offered by on-chip integration, there are also design

challenges that should be considered when placing voltage regulators on the same chip as the

load.

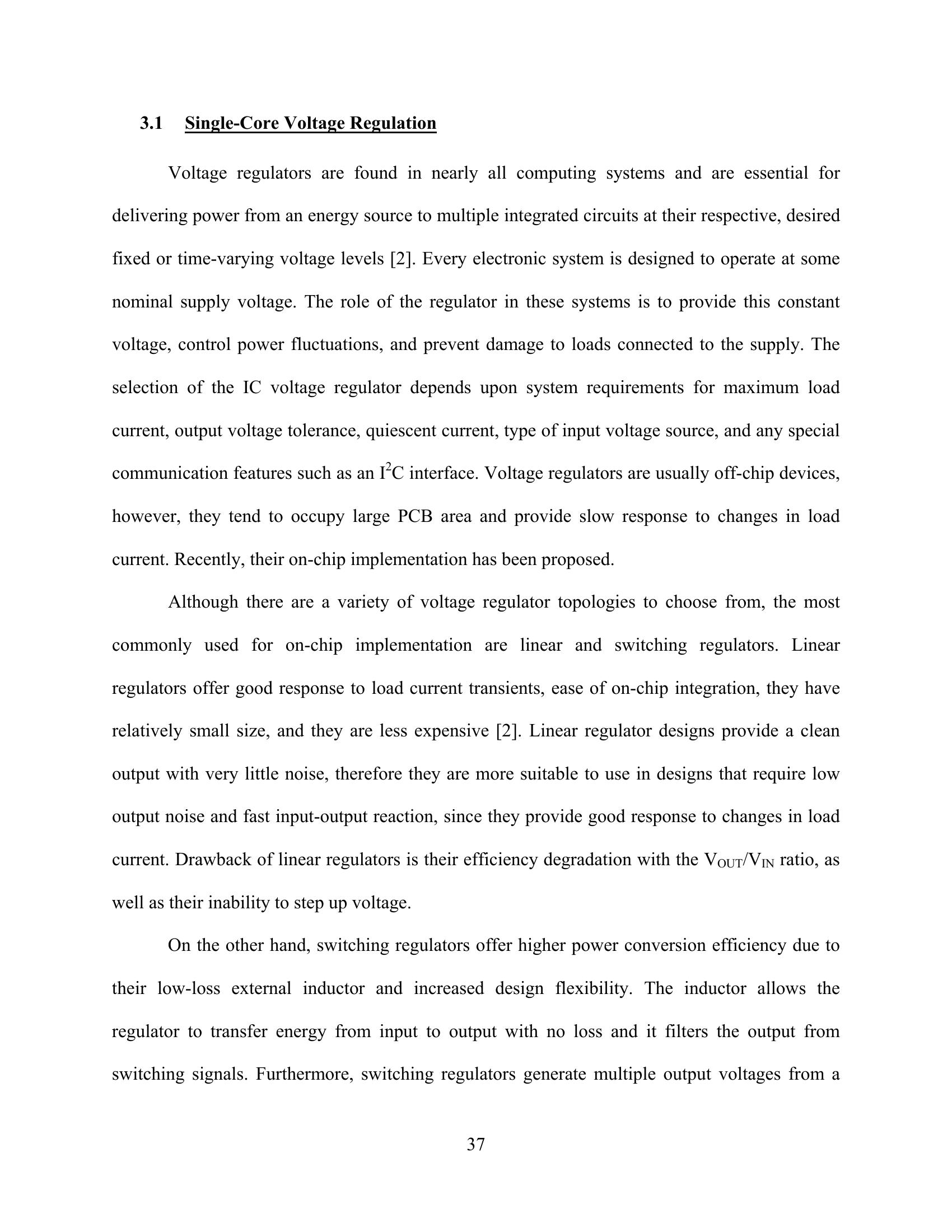

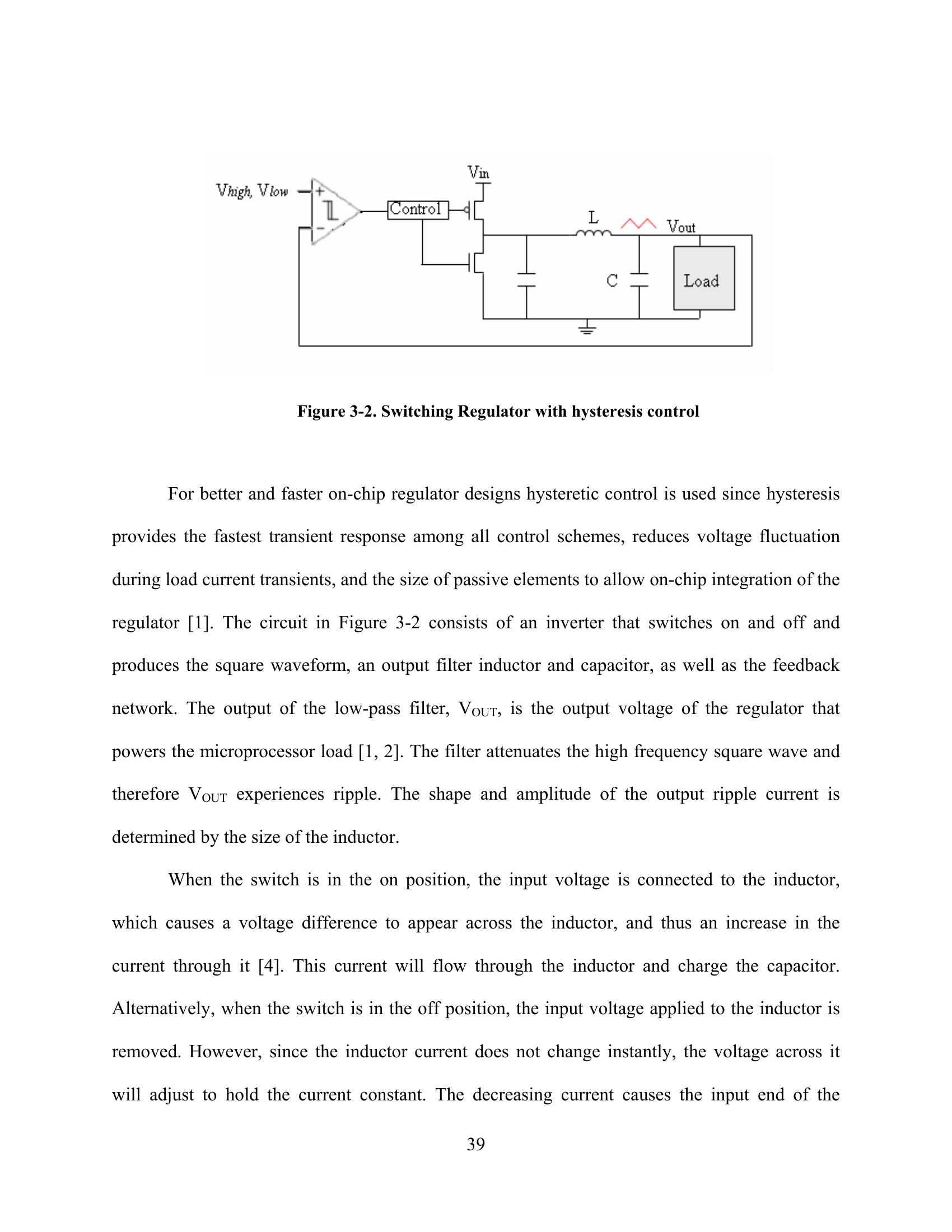

3.2 Buck-Type Switching Regulator for On-Chip Implementation

Since most of the circuit supply voltages are lower than the voltage of the primary source

to the board, such as the battery, switching regulators are used to step down the voltage [5].

Therefore, the most commonly used switching converter is the buck converter, shown in Figure

3-2. This converter topology uses an inverter that switches on and off and alternately connects

and disconnects the input voltage to the external inductor, which is connected to the output

terminal and its current is equal to the output current.

38

Figure 3-2. Switching Regulator with hysteresis control

For better and faster on-chip regulator designs hysteretic control is used since hysteresis

provides the fastest transient response among all control schemes, reduces voltage fluctuation

during load current transients, and the size of passive elements to allow on-chip integration of the

regulator [1]. The circuit in Figure 3-2 consists of an inverter that switches on and off and

produces the square waveform, an output filter inductor and capacitor, as well as the feedback

network. The output of the low-pass filter, V , is the output voltage of the regulator that

OUT

powers the microprocessor load [1, 2]. The filter attenuates the high frequency square wave and

therefore V experiences ripple. The shape and amplitude of the output ripple current is

OUT

determined by the size of the inductor.

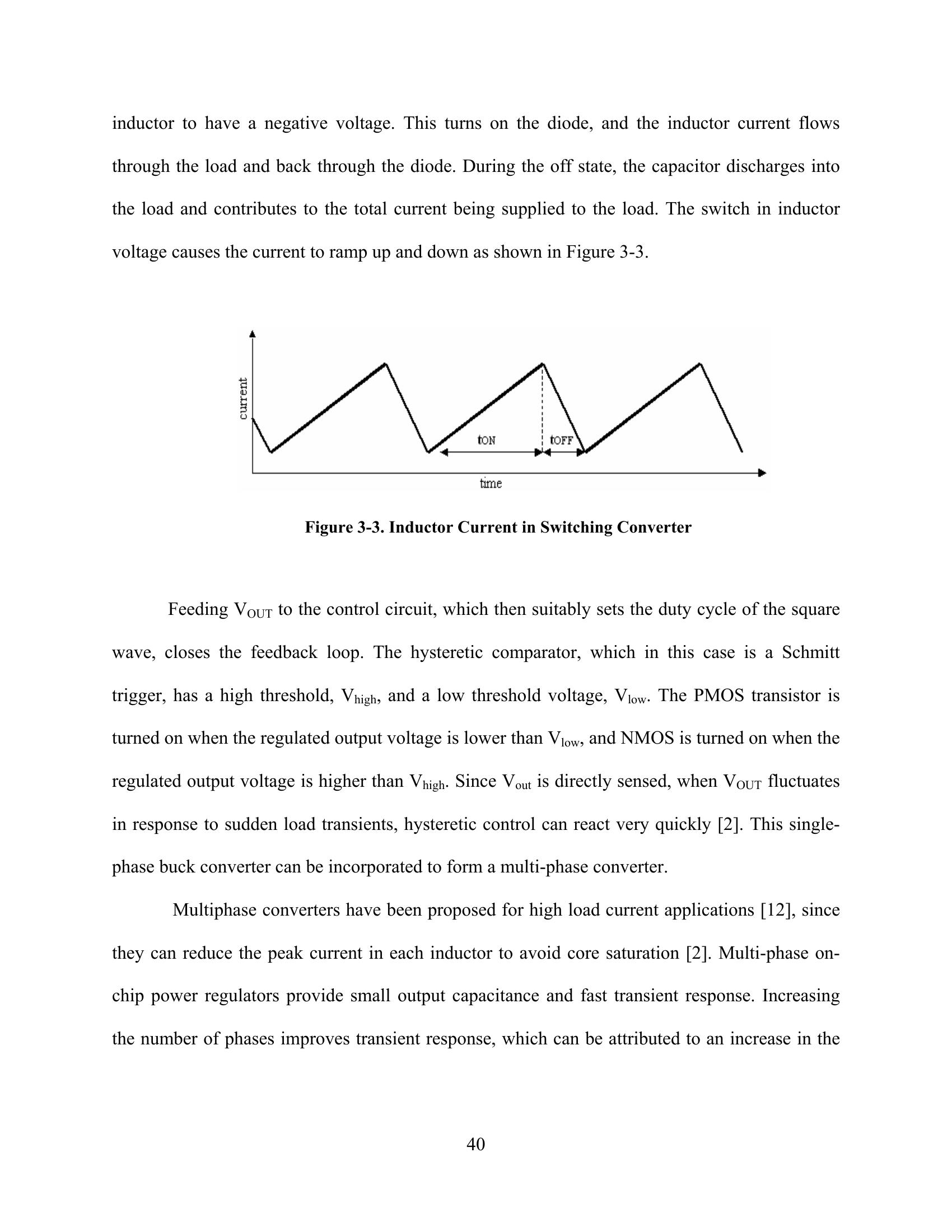

When the switch is in the on position, the input voltage is connected to the inductor,

which causes a voltage difference to appear across the inductor, and thus an increase in the

current through it [4]. This current will flow through the inductor and charge the capacitor.

Alternatively, when the switch is in the off position, the input voltage applied to the inductor is

removed. However, since the inductor current does not change instantly, the voltage across it

will adjust to hold the current constant. The decreasing current causes the input end of the

39

inductor to have a negative voltage. This turns on the diode, and the inductor current flows

through the load and back through the diode. During the off state, the capacitor discharges into

the load and contributes to the total current being supplied to the load. The switch in inductor

voltage causes the current to ramp up and down as shown in Figure 3-3.

Figure 3-3. Inductor Current in Switching Converter

Feeding V to the control circuit, which then suitably sets the duty cycle of the square

OUT

wave, closes the feedback loop. The hysteretic comparator, which in this case is a Schmitt

trigger, has a high threshold, V , and a low threshold voltage, V . The PMOS transistor is

high low

turned on when the regulated output voltage is lower than V , and NMOS is turned on when the

low

regulated output voltage is higher than V . Since V is directly sensed, when V fluctuates

high out OUT

in response to sudden load transients, hysteretic control can react very quickly [2]. This single-

phase buck converter can be incorporated to form a multi-phase converter.

Multiphase converters have been proposed for high load current applications [12], since

they can reduce the peak current in each inductor to avoid core saturation [2]. Multi-phase on-

chip power regulators provide small output capacitance and fast transient response. Increasing

the number of phases improves transient response, which can be attributed to an increase in the

40

effective switching frequency with more phases [1, 2]. However, large number of phases results

in large chip area, which is a major overhead introduced by this technique.

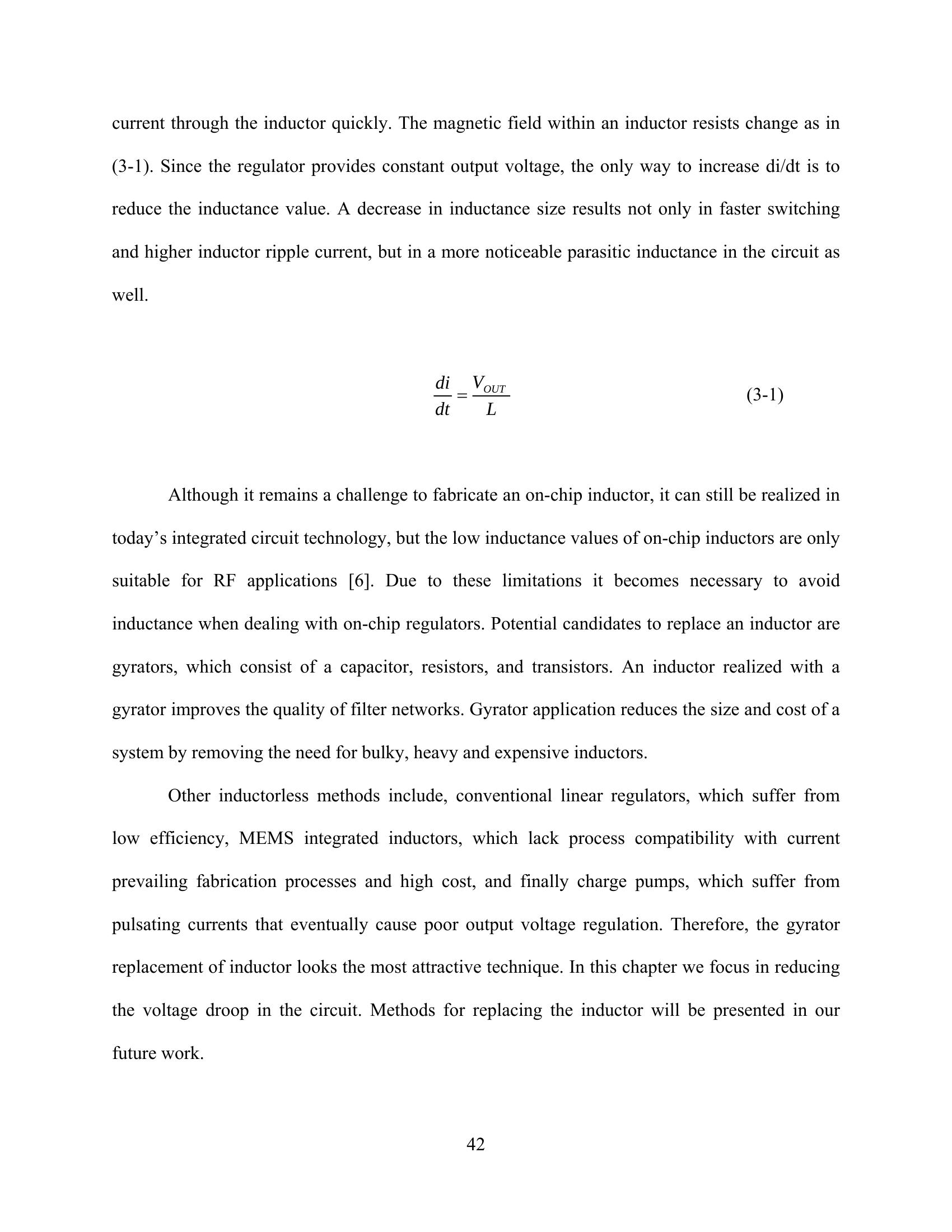

3.3 Implementation Challenges

Motivation for on-chip integration of voltage regulators is guided by increasing demand

for high-performance processor designs with improved power delivery networks. In addition, on-

chip integration saves PCB area and cost. When the regulator is placed close to the load, it

responds quicker to changes in load current thus resulting in fast voltage switching and also low

power microprocessor designs. However, there are many overheads associated with on-chip

integration and they need to be addressed. Since the regulator is moved on-chip the sizes of its

filter components are reduced. Smaller filter components result in higher switching frequencies,

which make the regulator less efficient. Also, a smaller capacitor size results in less charge

stored, which means less charge available to the load, which then introduces higher vulnerability

to large di/dt events that can cause large voltage fluctuations [1].

In order to reduce fluctuations, decoupling capacitors are used but with the overhead of

increasing chip area. A solution to this problem would be that the on-chip regulator uses the filter

capacitor for both decoupling and filtering. However, since the on-chip capacitor is much smaller

than the total decoupling and filter capacitance used for off-chip regulators, large load current

steps can rapidly drain out the limited charge stored on the capacitor before the regulator loop

can respond, resulting in a large voltage droop [2].

Circuit droops are assisted by filter component size reduction. In addition to the

aforementioned overheads, inductance issues are a major concern as well. Each generation of

processors demands faster transient response times, which requires the ability to change the

41

current through the inductor quickly. The magnetic field within an inductor resists change as in

(3-1). Since the regulator provides constant output voltage, the only way to increase di/dt is to

reduce the inductance value. A decrease in inductance size results not only in faster switching

and higher inductor ripple current, but in a more noticeable parasitic inductance in the circuit as

well.

di V

= OUT (3-1)

dt L

Although it remains a challenge to fabricate an on-chip inductor, it can still be realized in

today’s integrated circuit technology, but the low inductance values of on-chip inductors are only

suitable for RF applications [6]. Due to these limitations it becomes necessary to avoid

inductance when dealing with on-chip regulators. Potential candidates to replace an inductor are

gyrators, which consist of a capacitor, resistors, and transistors. An inductor realized with a

gyrator improves the quality of filter networks. Gyrator application reduces the size and cost of a

system by removing the need for bulky, heavy and expensive inductors.

Other inductorless methods include, conventional linear regulators, which suffer from

low efficiency, MEMS integrated inductors, which lack process compatibility with current

prevailing fabrication processes and high cost, and finally charge pumps, which suffer from

pulsating currents that eventually cause poor output voltage regulation. Therefore, the gyrator

replacement of inductor looks the most attractive technique. In this chapter we focus in reducing

the voltage droop in the circuit. Methods for replacing the inductor will be presented in our

future work.

42

3.4 Hot Swap Controller Solution

When the voltage regulator is implemented on-chip, the sizes of filter elements are

reduced due to high switching frequencies. As a result, the circuit becomes more vulnerable to

voltage droops and current surges. A smaller capacitor stores less charge and if the load is

experiencing a large current step it will quickly drain this small amount of charge stored, thus

resulting in output voltage droop. Also, switching power supplies experience inrush currents at

turn on due to switching elements, which is undesirable for the load. In order to eliminate these

effects a hot swap controller is proposed. Our simulations are performed with the controller and

regulator placed off-chip and located between the source and the load, as shown in Figure 3-4.

Figure 3-4. Regulator off-chip a) without controller and b) with controller

The results show that this technique is effective in protecting the load from the droop and

is a good candidate for on-chip implementation. The controller limits the inrush current by

slowly decreasing the on-resistance of the N-Channel MOSFET. It also provides protection

against high voltage transients and over- and under-voltage defects, load glitches, and short

circuit [35, 47]. When the circuit starts powering up, circuit components have an immediate need

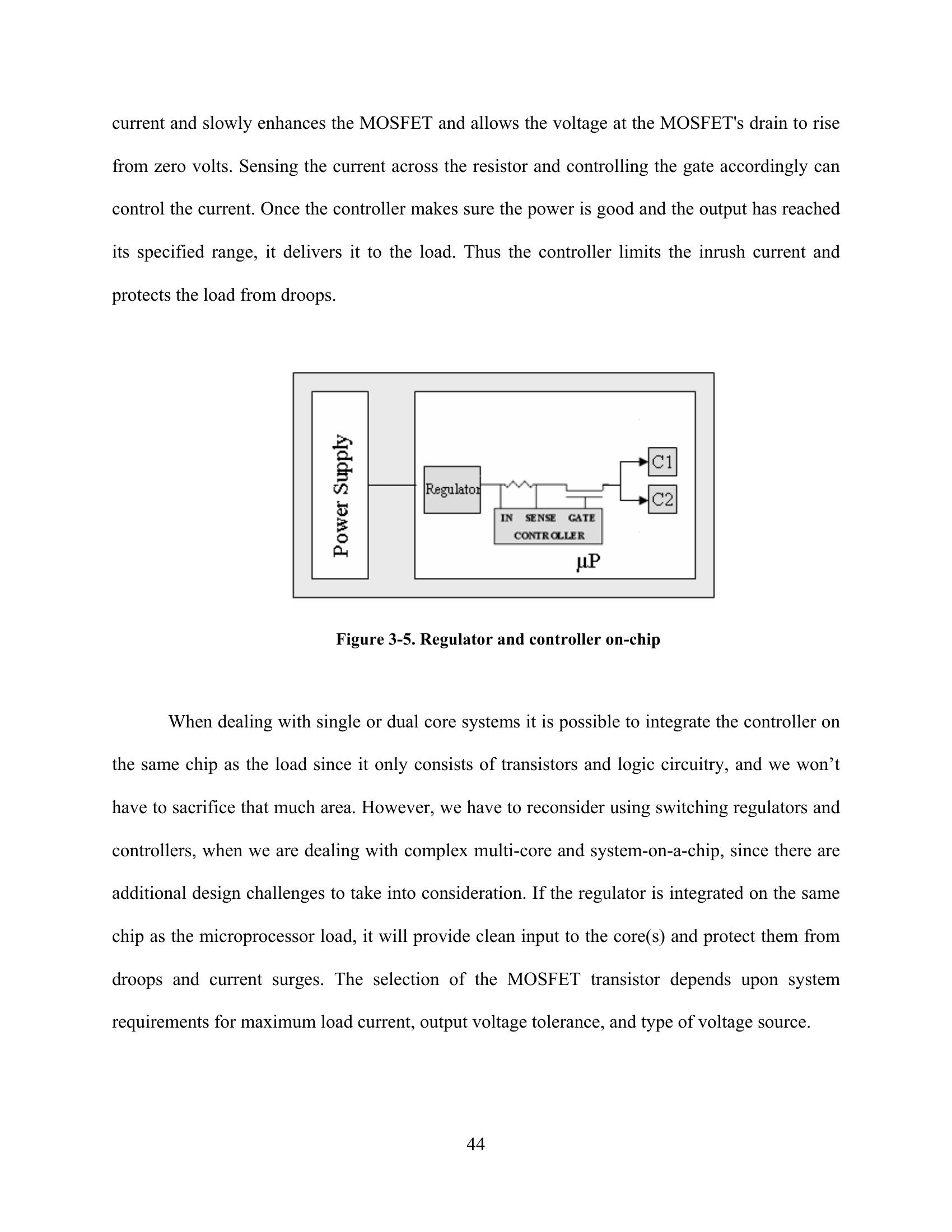

to extract a large transient current from the voltage source. The controller monitors this inrush

43

current and slowly enhances the MOSFET and allows the voltage at the MOSFET’s drain to rise

from zero volts. Sensing the current across the resistor and controlling the gate accordingly can

control the current. Once the controller makes sure the power is good and the output has reached

its specified range, it delivers it to the load. Thus the controller limits the inrush current and

protects the load from droops.

Figure 3-5. Regulator and controller on-chip

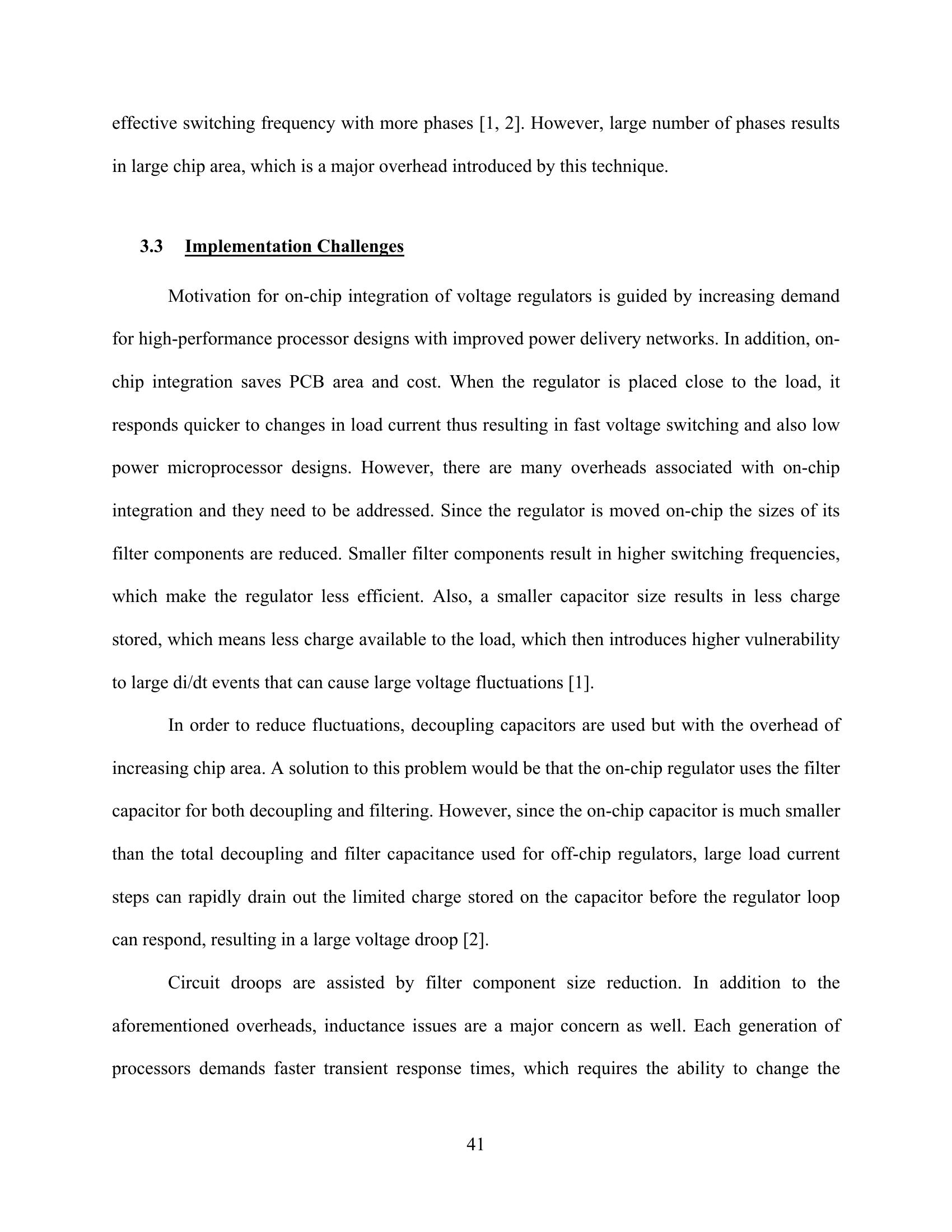

When dealing with single or dual core systems it is possible to integrate the controller on

the same chip as the load since it only consists of transistors and logic circuitry, and we won’t

have to sacrifice that much area. However, we have to reconsider using switching regulators and

controllers, when we are dealing with complex multi-core and system-on-a-chip, since there are

additional design challenges to take into consideration. If the regulator is integrated on the same

chip as the microprocessor load, it will provide clean input to the core(s) and protect them from

droops and current surges. The selection of the MOSFET transistor depends upon system

requirements for maximum load current, output voltage tolerance, and type of voltage source.

44

25

20

15

10

5

0

5.00 5.05 5.10 5.15 5.20 5.25 5.30 5.35 5.40 5.45 5.50

-5

-10

-15

-20

-25

Time(ms)

45

)A(tnerruC

I(Supply)

I(Load)

Figure 3-6. Inrush current effects in the supply and load

10

5

0

5.00 5.10 5.20 5.30 5.40 5.50

-5

-10

-15

-20

-25

Time(ms)

)A(tnerruC

I(Supply)

I(Load)

Figure 3-7. Inrush current protection

| I(S | ||||||||

| None | None | None | None | None | None | None | None | upply) |

| I(L | oad) | |||||||

| 00 5. | 05 5. | 10 5. | 15 5. | 20 5.2 | 5 5.30 | 5.35 | 5.40 5. | 45 5 |

| 0 5.1 | 0 5. | 20 5.30 | 5 | .40 5.5 |

| I(Supply) I(Load) |

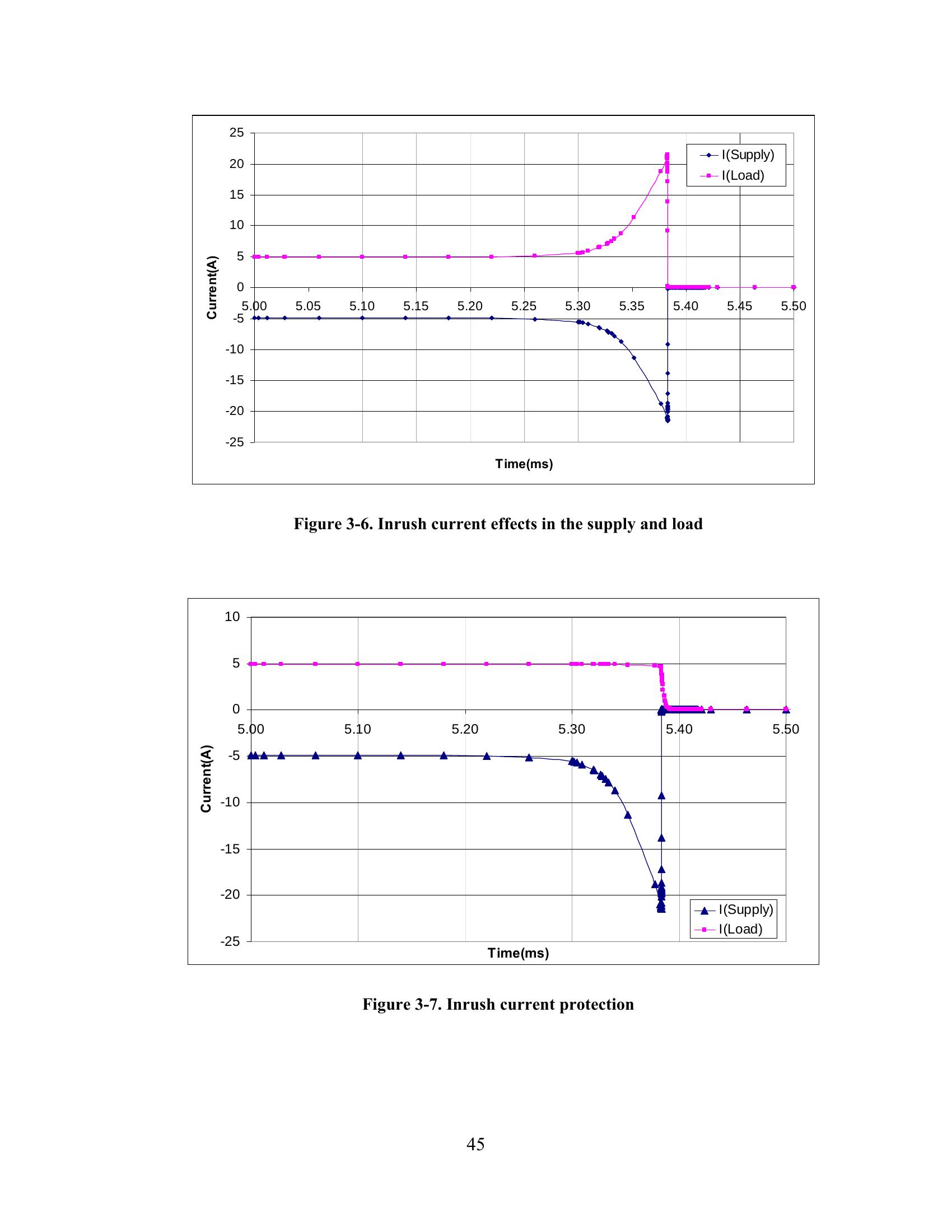

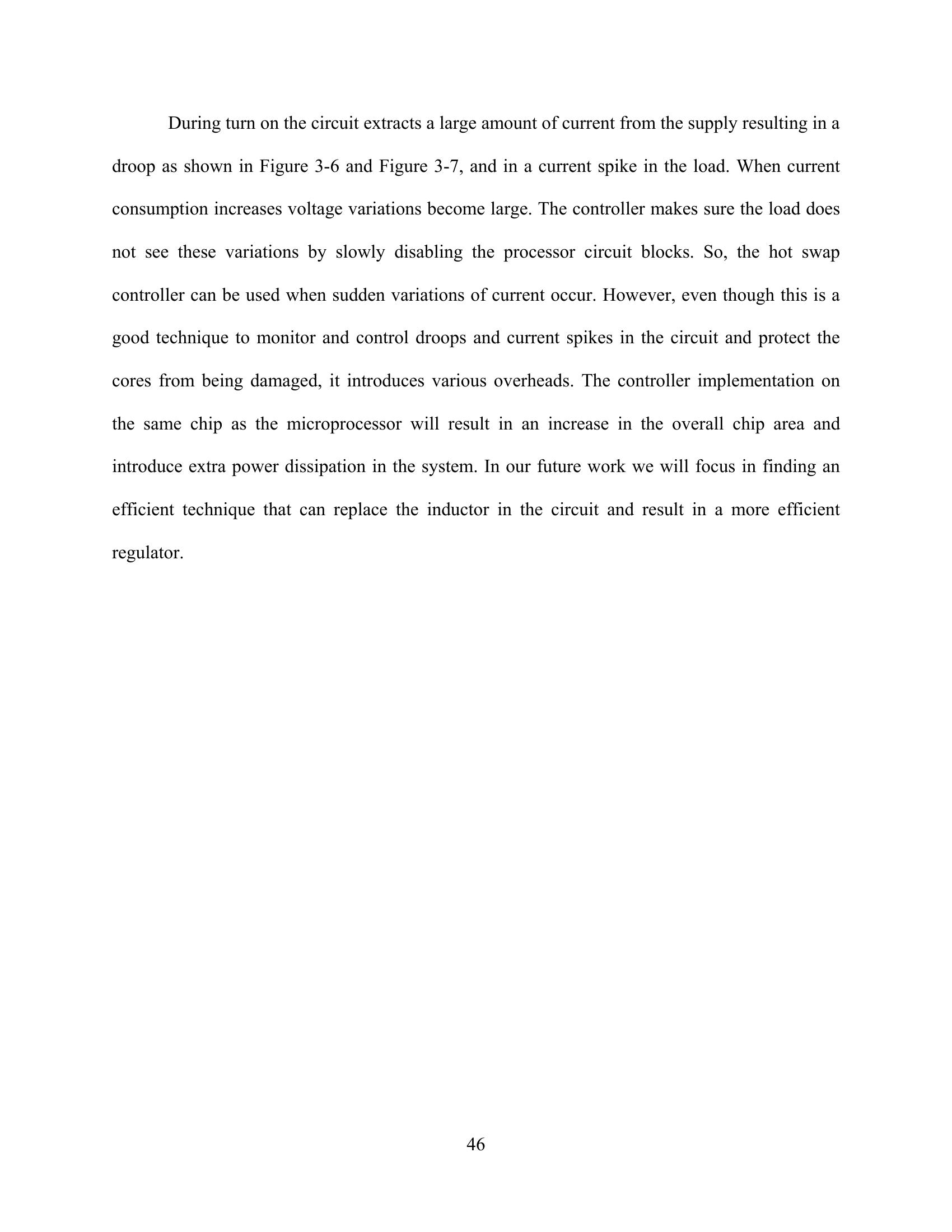

During turn on the circuit extracts a large amount of current from the supply resulting in a

droop as shown in Figure 3-6 and Figure 3-7, and in a current spike in the load. When current

consumption increases voltage variations become large. The controller makes sure the load does

not see these variations by slowly disabling the processor circuit blocks. So, the hot swap

controller can be used when sudden variations of current occur. However, even though this is a

good technique to monitor and control droops and current spikes in the circuit and protect the

cores from being damaged, it introduces various overheads. The controller implementation on

the same chip as the microprocessor will result in an increase in the overall chip area and

introduce extra power dissipation in the system. In our future work we will focus in finding an

efficient technique that can replace the inductor in the circuit and result in a more efficient

regulator.

46

4 TWO-STAGE APPROACH FOR VOLTAGE REGULATOR

IMPLEMENTATION IN SOC

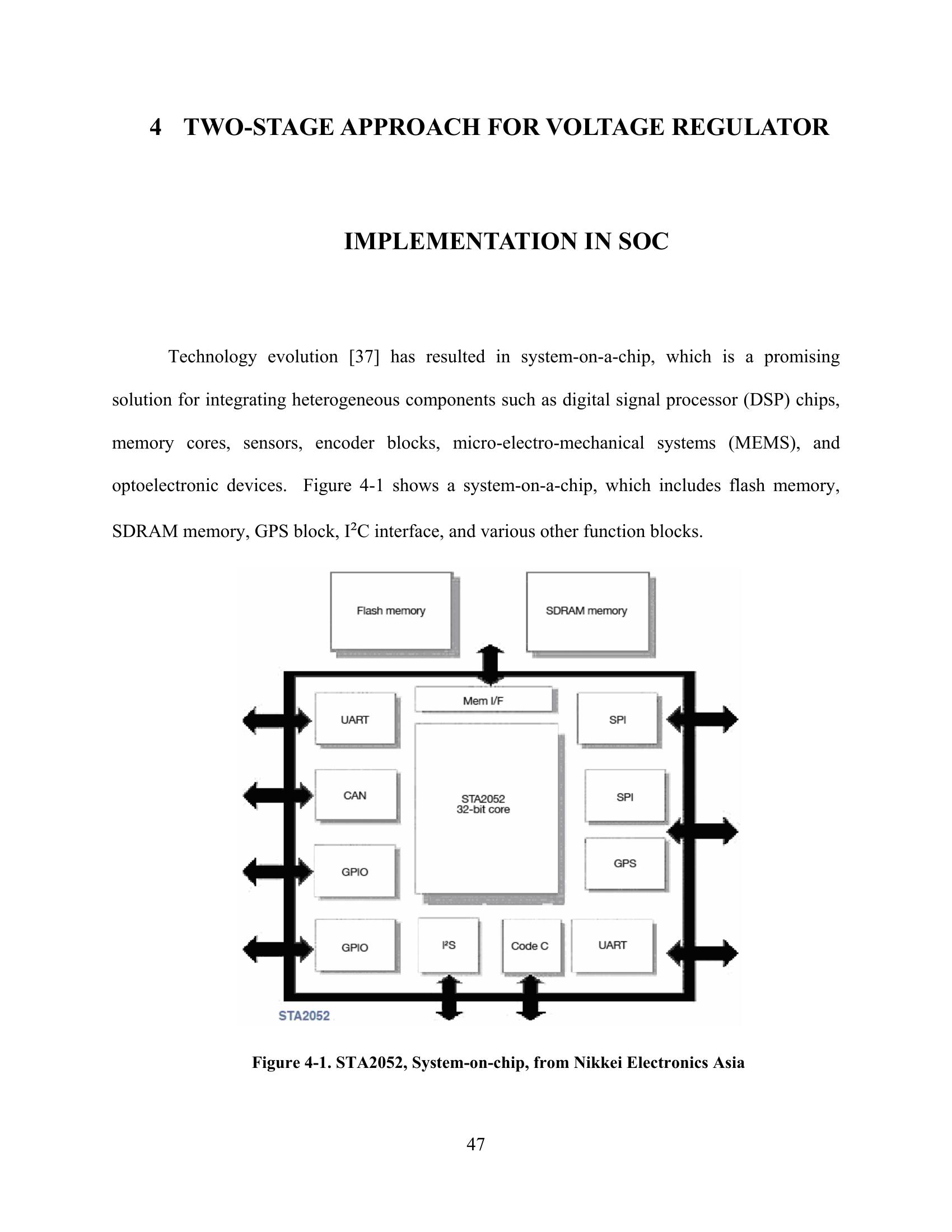

Technology evolution [37] has resulted in system-on-a-chip, which is a promising

solution for integrating heterogeneous components such as digital signal processor (DSP) chips,

memory cores, sensors, encoder blocks, micro-electro-mechanical systems (MEMS), and

optoelectronic devices. Figure 4-1 shows a system-on-a-chip, which includes flash memory,

SDRAM memory, GPS block, I²C interface, and various other function blocks.

Figure 4-1. STA2052, System-on-chip, from Nikkei Electronics Asia

47

As Figure 4-1 reveals, SOC design includes highly integrated mixed-signal integrated

circuits, which are popular due to their low-cost, low power, and low-area [18]. Since analog and

digital parts are integrated on the same chip along with a large number of cores, there will be

issues related to management of power consumption and temperature, both of which directly

affect the SOC reliability [19]. Due to the increase in circuit density, analog and digital parts are

in close proximity, which causes signal noise. Therefore, voltage regulator becomes a crucial

component of the power management system. Voltage regulators provide constant voltage and

filter fluctuations that are generated from the power supply, thus protecting the load from seeing

the ripple that comes from the input.

The regulator needs to be designed according to function block specifications and provide

good efficiency and transient response characteristics. The voltage regulator typically resides

between the source and each load. Since an SOC includes the integration of various function

blocks, multiple voltage domains are needed. Multiple supply voltages provide an effective

technique for power optimization [24], which results in better performance, low power

dissipation, and evenly distributed heat dissipation. This strategy has also the advantage of

allowing modules along the critical paths to operate with the highest available voltage level,

while permitting modules along non-critical paths to use a lower voltage [26], thus decreasing

energy consumption.

48

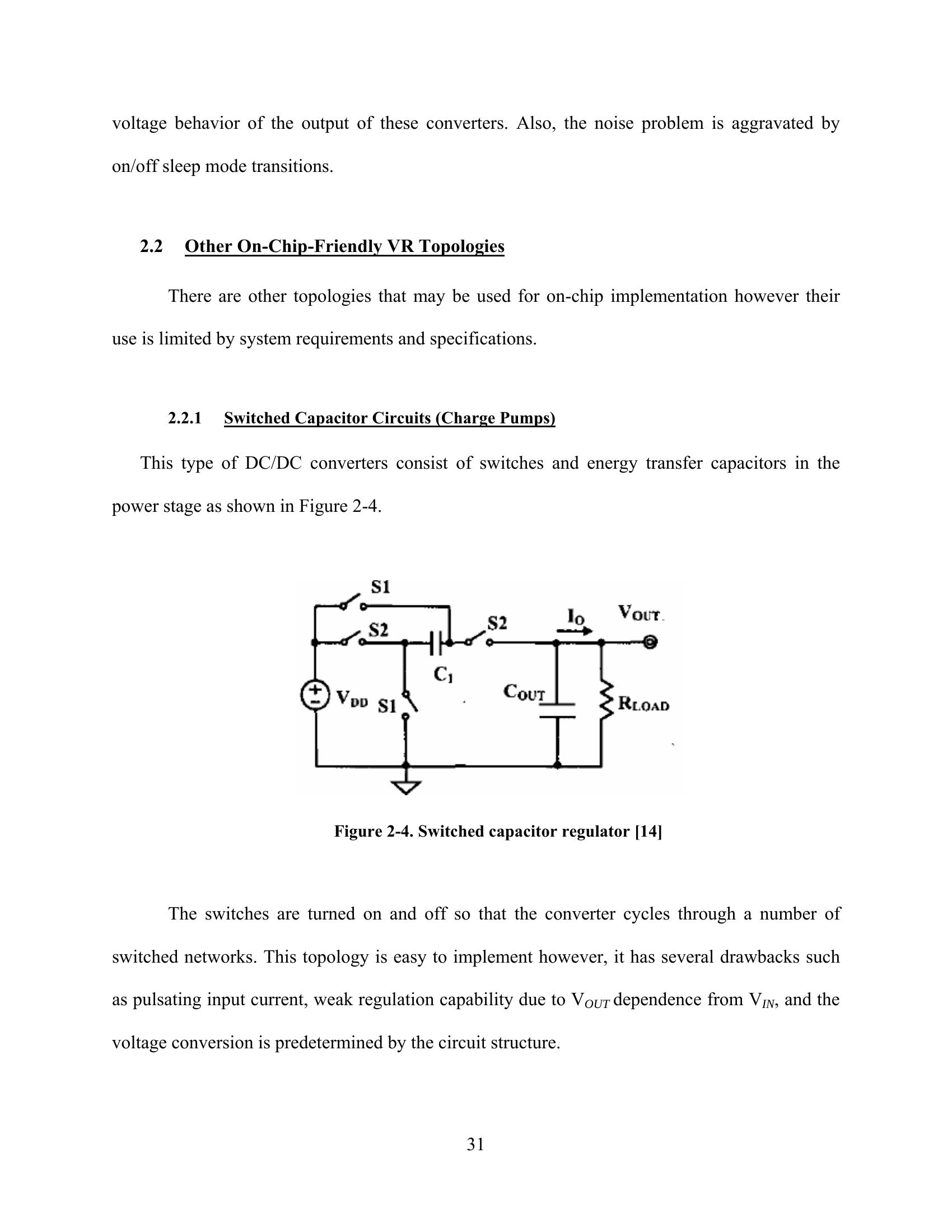

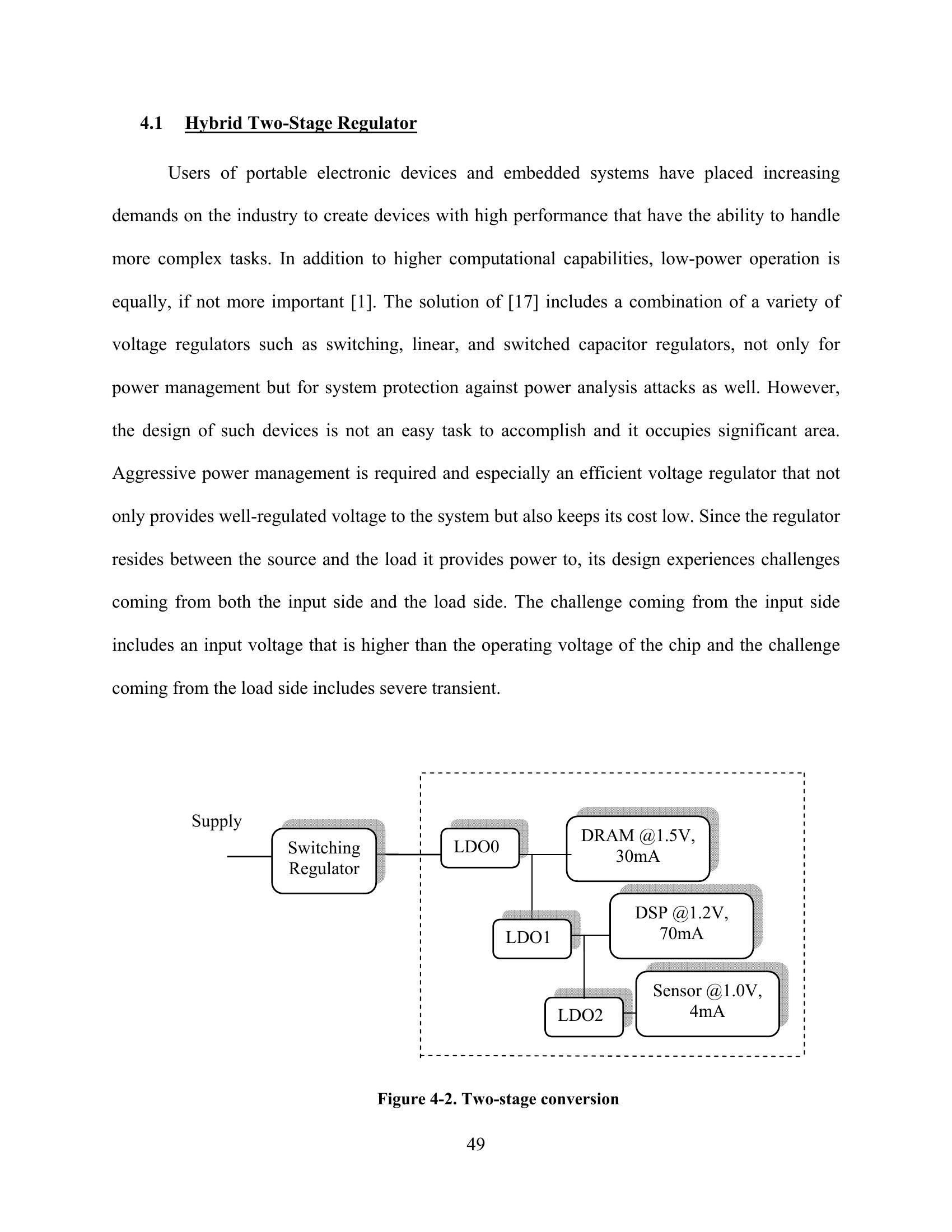

4.1 Hybrid Two-Stage Regulator

Users of portable electronic devices and embedded systems have placed increasing

demands on the industry to create devices with high performance that have the ability to handle

more complex tasks. In addition to higher computational capabilities, low-power operation is

equally, if not more important [1]. The solution of [17] includes a combination of a variety of

voltage regulators such as switching, linear, and switched capacitor regulators, not only for

power management but for system protection against power analysis attacks as well. However,

the design of such devices is not an easy task to accomplish and it occupies significant area.

Aggressive power management is required and especially an efficient voltage regulator that not

only provides well-regulated voltage to the system but also keeps its cost low. Since the regulator

resides between the source and the load it provides power to, its design experiences challenges

coming from both the input side and the load side. The challenge coming from the input side

includes an input voltage that is higher than the operating voltage of the chip and the challenge

coming from the load side includes severe transient.

Supply

DRAM @1.5V,

Switching LDO0

30mA

Regulator

DSP @1.2V,

LDO1 70mA

Sensor @1.0V,

LDO2 4mA

Figure 4-2. Two-stage conversion

49

Furthermore, since the load is a system-on-a-chip employing many functional blocks it is

very difficult for the single-stage converter to handle challenges from both sides. In other words,

we need a two-stage conversion where the first stage steps down the voltage from the power

supply and the second stage steps it down to bring it close to the level required by the load. If

both of these regulator stages are placed off-chip it would not improve the transient response due

to interconnect parasitic components that would still fall between the regulator and the load. On

the other hand, due to their large size, complexity, and cost it is not practical to place switching

regulators on the same chip as the load. Therefore, the first stage, a switching regulator, will be

placed off-chip and the second stage, a tree design of low dropout linear regulators, will be

placed on the same chip as the load. This improves the transient response of the regulator and it

also reduces the noise produced by the switching regulator.

Buck-type switching regulator is used as first stage since it is needed to step down the

battery voltage to a lower level as required by the SOC. In addition, the efficiency of switching

regulators is generally higher than efficiency of linear regulators due to the presence of the

inductor as low loss device. In this design a high efficiency first stage is needed since it will

provide power to the second stage therefore the switching regulator is placed off-chip. The buck

converter generates the 1.8V bus at a higher efficiency than the LDO. Low dropout linear

regulators are used as the second stage and placed on-chip due to their small size, low cost,

simplicity, and the ability to reduce fluctuations coming from the power source. The switching

regulator – LDO solution uses a buck converter to generate the 1.8V rail, and an LDO powered

from 1.8V to generate the 1.5V output. Then the 1.5V output will feed a DRAM chip and it will

also serve as input to second LDO. Second LDO will step down the voltage to 1.2V to feed a

DSP chip as specified in [34]. This 1.2V output will serve as input to third LDO, which will step

50

down the voltage to 1.0V and feed a sensor. This solution is a good overall compromise between

size, cost, heat dissipation, and efficiency.

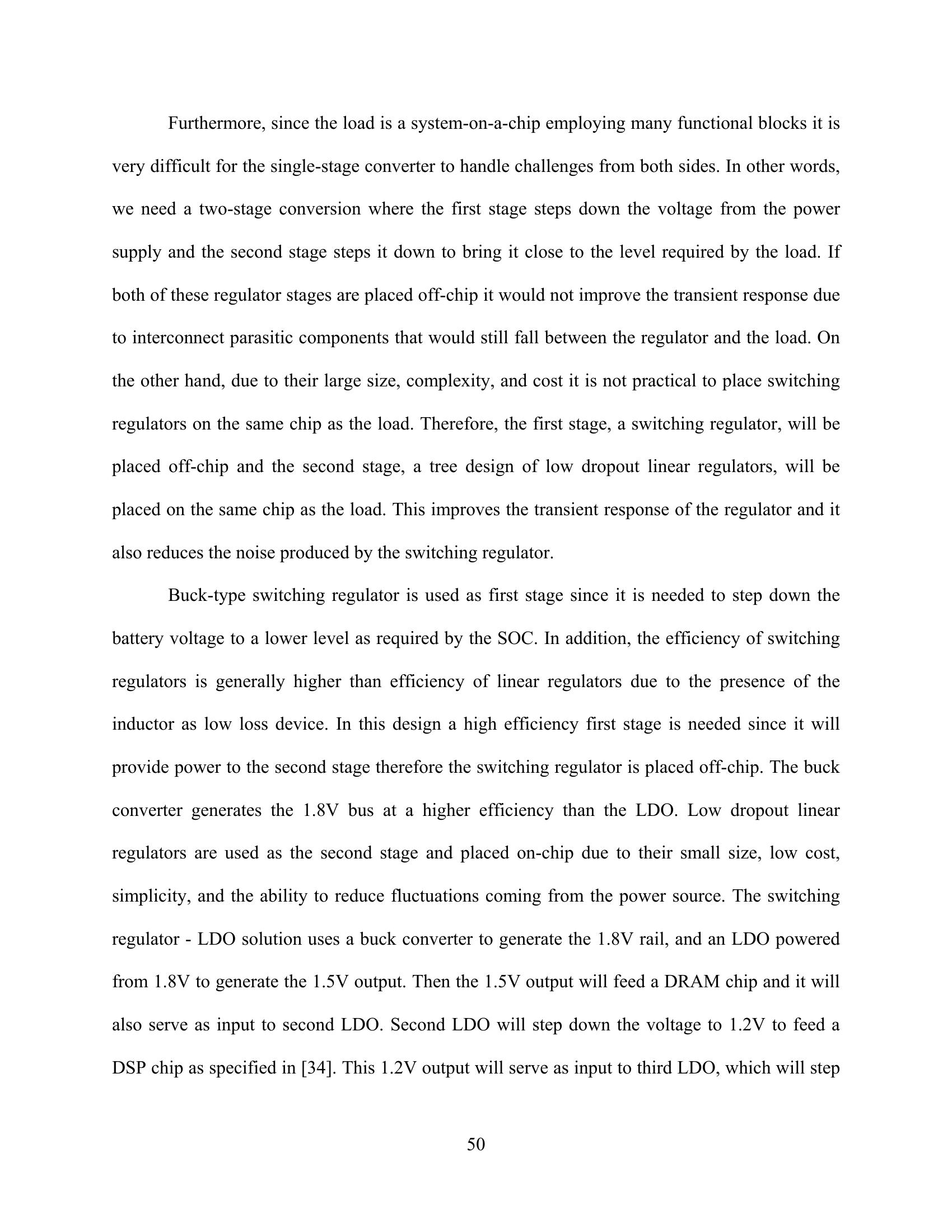

4.2 Stage 1: Switching Regulator

The first stage of this approach employs a switching regulator to step down the battery

voltage and serve as power source for the second stage.

Figure 4-3. Switching regulator

The switching regulator, shown in Figure 4-3, uses a PMOS transistor as a switch that

connects and disconnects the input voltage to the external inductor, which is connected to the

output terminal. Inductor current is equal to the output current. When the switch is in the ON

position, shown in Figure 4-4, the input voltage is connected to the inductor, which causes a

voltage difference to appear across the inductor, and thus an increase in the current through it [4].

This current will flow through the inductor and charge the capacitor.

Alternatively, when the switch is in the OFF position, Figure 4-5, the input voltage

applied to the inductor is removed. However, since the inductor current does not change

instantly, the voltage across it will adjust to hold the current constant. The decreasing current

causes the input end of the inductor to have a negative voltage. This turns on the diode, and the

51

inductor current flows through the load and back through the diode. During the OFF state, the

capacitor discharges into the load and contributes to the total current being supplied to the load.

The output of the LC low-pass filter, V , is the output voltage of the regulator that powers the

OUT

load. The filter attenuates the high frequency square wave and therefore V experiences ripple

OUT

[1, 2]. The intrinsic switched nature of these regulators not only produces ripples but also an

increment of electromagnetic interference in neighboring electronic systems [22]. Figure 4-4 and

Figure 4-5 show current flow in the switching regulator when the switch is closed and when it is

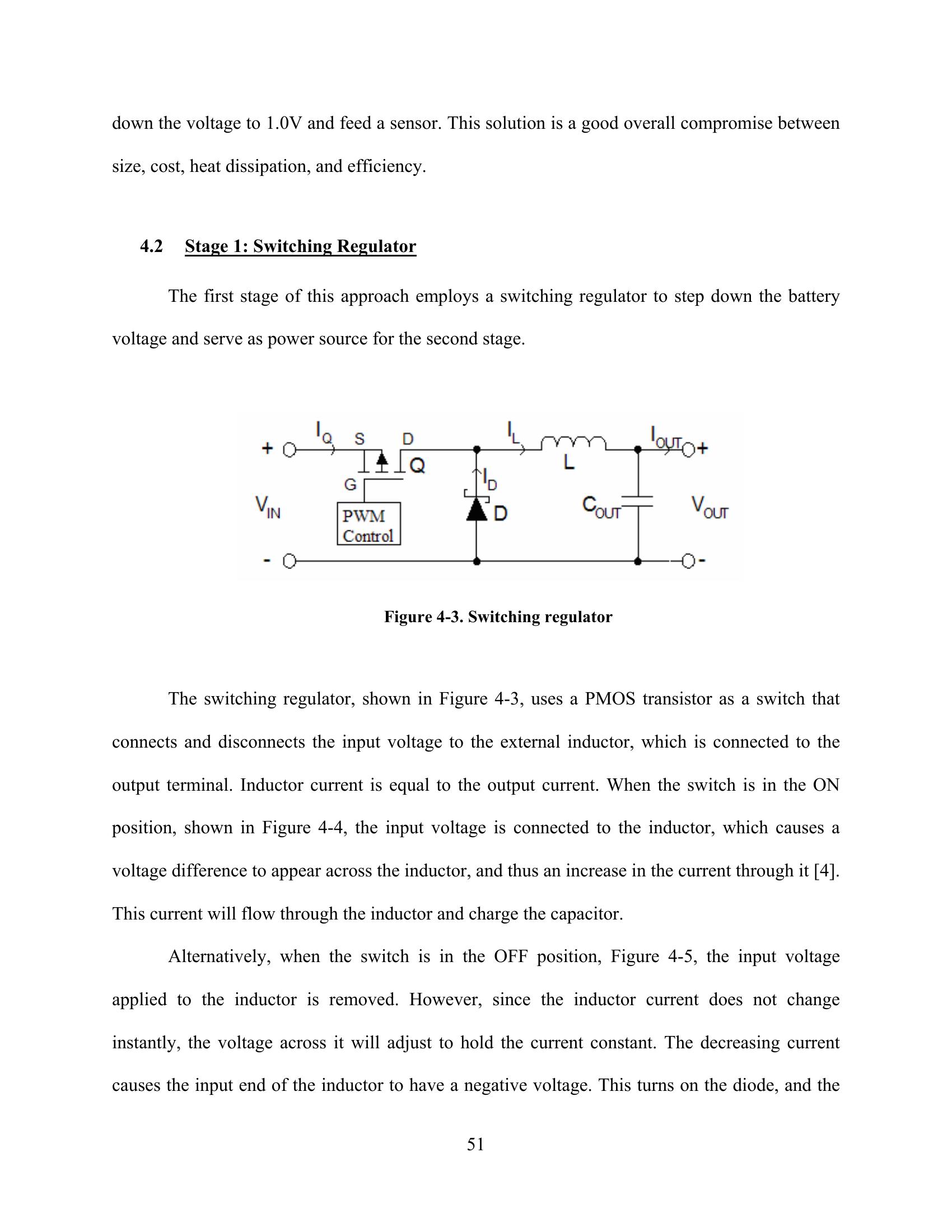

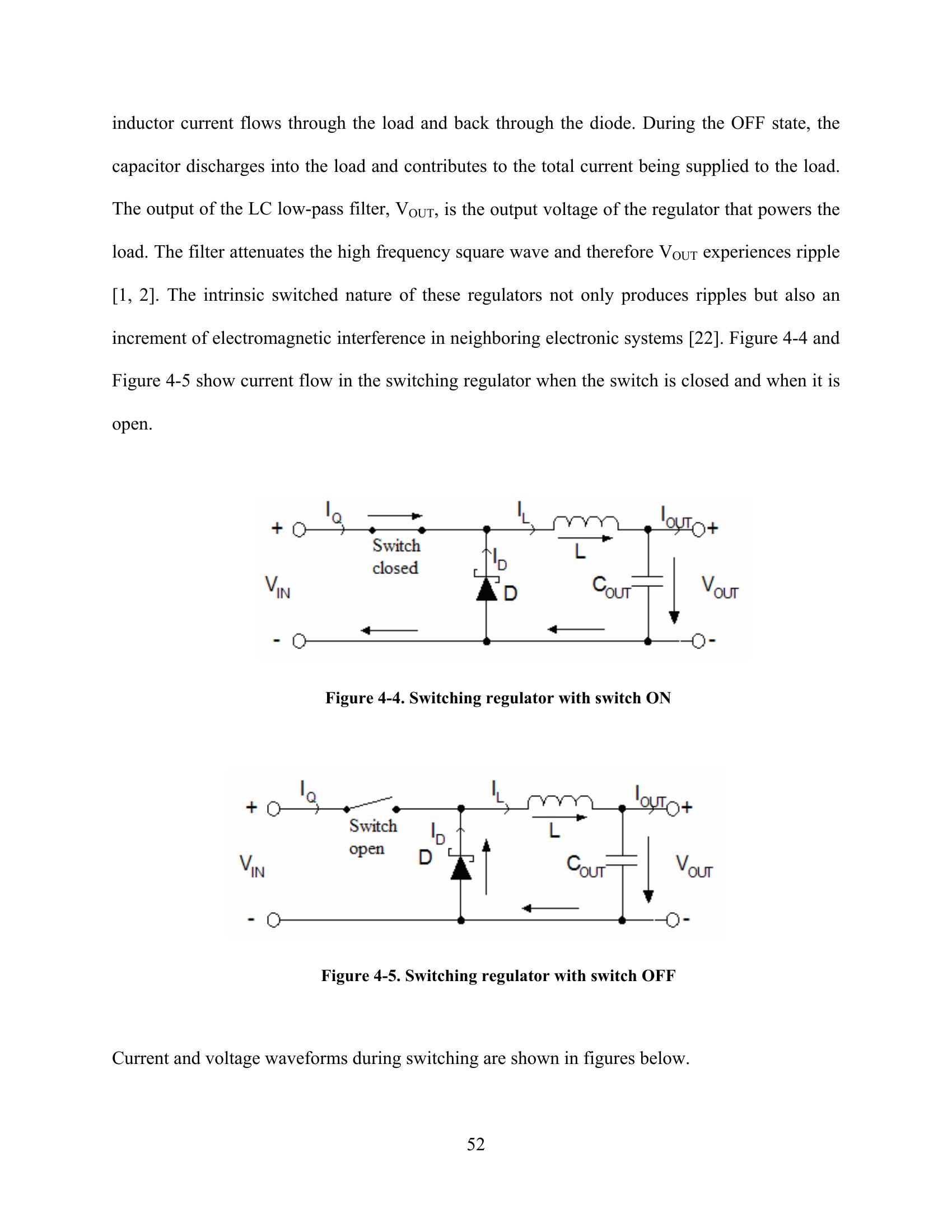

open.

Figure 4-4. Switching regulator with switch ON

Figure 4-5. Switching regulator with switch OFF

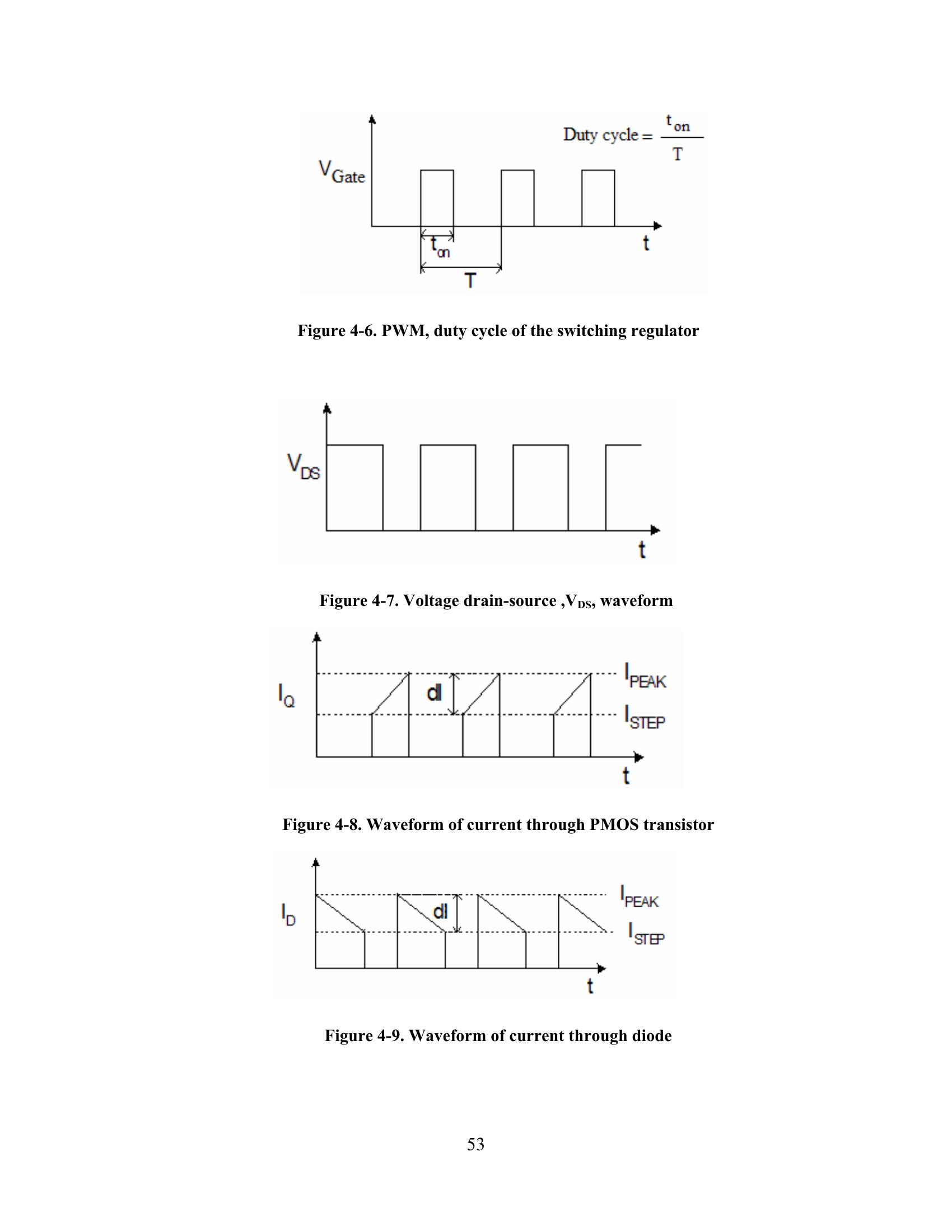

Current and voltage waveforms during switching are shown in figures below.

52

Figure 4-6. PWM, duty cycle of the switching regulator

Figure 4-7. Voltage drain-source ,V , waveform

DS

Figure 4-8. Waveform of current through PMOS transistor

Figure 4-9. Waveform of current through diode

53

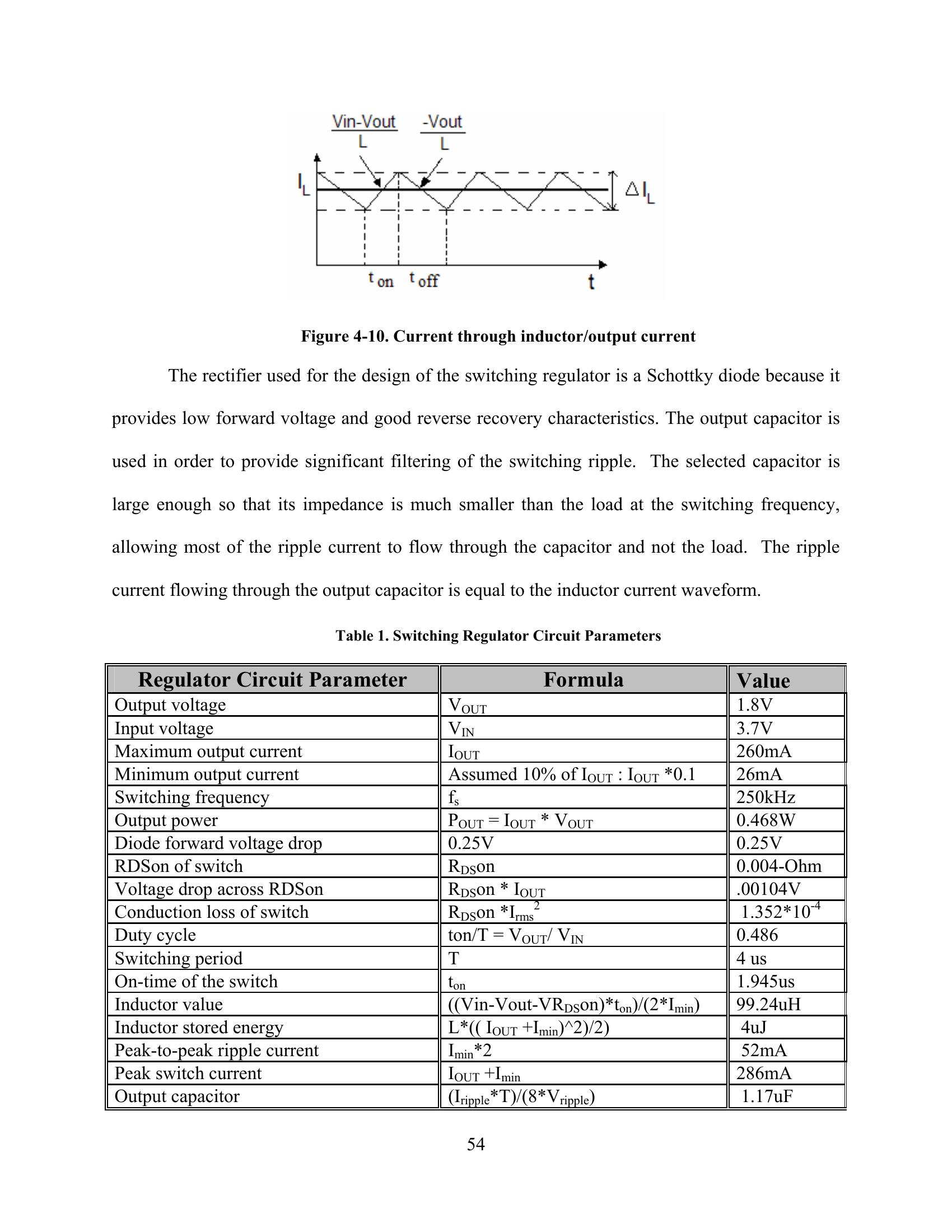

Figure 4-10. Current through inductor/output current

The rectifier used for the design of the switching regulator is a Schottky diode because it

provides low forward voltage and good reverse recovery characteristics. The output capacitor is

used in order to provide significant filtering of the switching ripple. The selected capacitor is

large enough so that its impedance is much smaller than the load at the switching frequency,

allowing most of the ripple current to flow through the capacitor and not the load. The ripple

current flowing through the output capacitor is equal to the inductor current waveform.

Table 1. Switching Regulator Circuit Parameters

Regulator Circuit Parameter Formula Value

Output voltage V 1.8V

OUT

Input voltage V 3.7V

IN

Maximum output current I 260mA

OUT

Minimum output current Assumed 10% of I : I *0.1 26mA

OUT OUT

Switching frequency f 250kHz

s

Output power P = I * V 0.468W

OUT OUT OUT

Diode forward voltage drop 0.25V 0.25V

RDSon of switch R on 0.004-Ohm

DS

Voltage drop across RDSon R on * I .00104V

DS OUT

Conduction loss of switch R on *I 2 1.352*10-4

DS rms

Duty cycle ton/T = V / V 0.486

OUT IN

Switching period T 4 us

On-time of the switch t 1.945us

on

Inductor value ((Vin-Vout-VR on)*t )/(2*I ) 99.24uH

DS on min

Inductor stored energy L*(( I +I )^2)/2) 4uJ

OUT min

Peak-to-peak ripple current I *2 52mA

min

Peak switch current I +I 286mA

OUT min

Output capacitor (I *T)/(8*V ) 1.17uF

ripple ripple

54

| Regulator Circuit Parameter | Formula | Value | ||||||

| Output voltage | None | None | V OUT | None | None | 1.8V | None | None |

| Input voltage | None | None | V IN | None | None | 3.7V | None | None |

| Maximum output current | None | None | I OUT | None | None | 260mA | None | None |

| Minimum output current | None | None | Assumed 10% of I : I *0.1 OUT OUT | None | None | 26mA | None | None |

| Switching frequency | None | None | f s | None | None | 250kHz | None | None |

| Output power | None | None | P = I * V OUT OUT OUT | None | None | 0.468W | None | None |

| Diode forward voltage drop | None | None | 0.25V | None | None | 0.25V | None | None |

| RDSon of switch | None | None | R on DS | None | None | 0.004-Ohm | None | None |

| Voltage drop across RDSon | None | None | R on * I DS OUT | None | None | .00104V | None | None |

| Conduction loss of switch | None | None | R on *I 2 DS rms | None | None | 1.352*10-4 | None | None |

| Duty cycle | None | None | ton/T = V / V OUT IN | None | None | 0.486 | None | None |

| Switching period | None | None | T | None | None | 4 us | None | None |

| On-time of the switch | None | None | t on | None | None | 1.945us | None | None |

| Inductor value | None | None | ((Vin-Vout-VR on)*t )/(2*I ) DS on min | None | None | 99.24uH | None | None |

| Inductor stored energy | None | None | L*(( I +I )^2)/2) OUT min | None | None | 4uJ | None | None |

| Peak-to-peak ripple current | None | None | I *2 min | None | None | 52mA | None | None |

| Peak switch current | None | None | I +I OUT min | None | None | 286mA | None | None |

| Output capacitor | None | None | (I *T)/(8*V ) ripple ripple | None | None | 1.17uF | None | None |

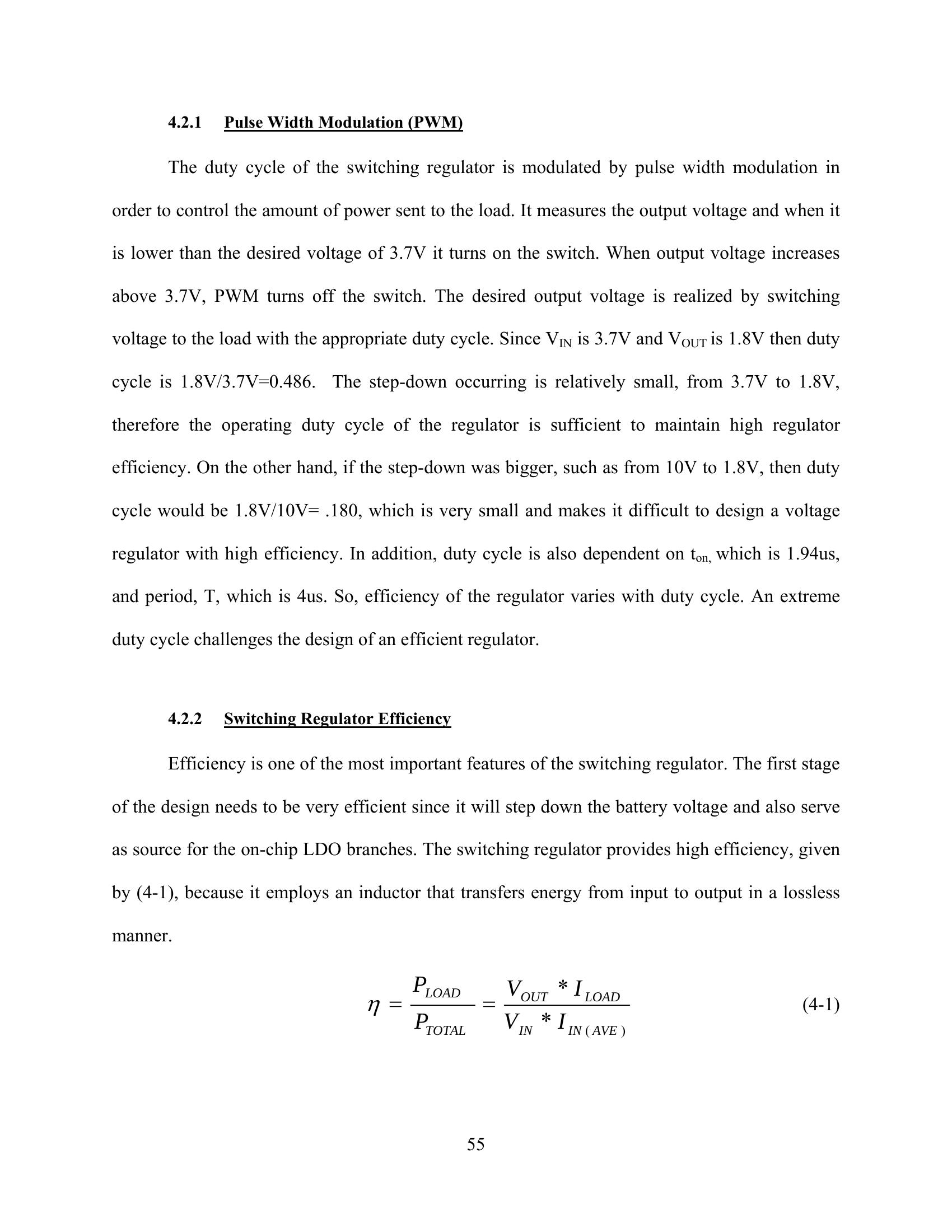

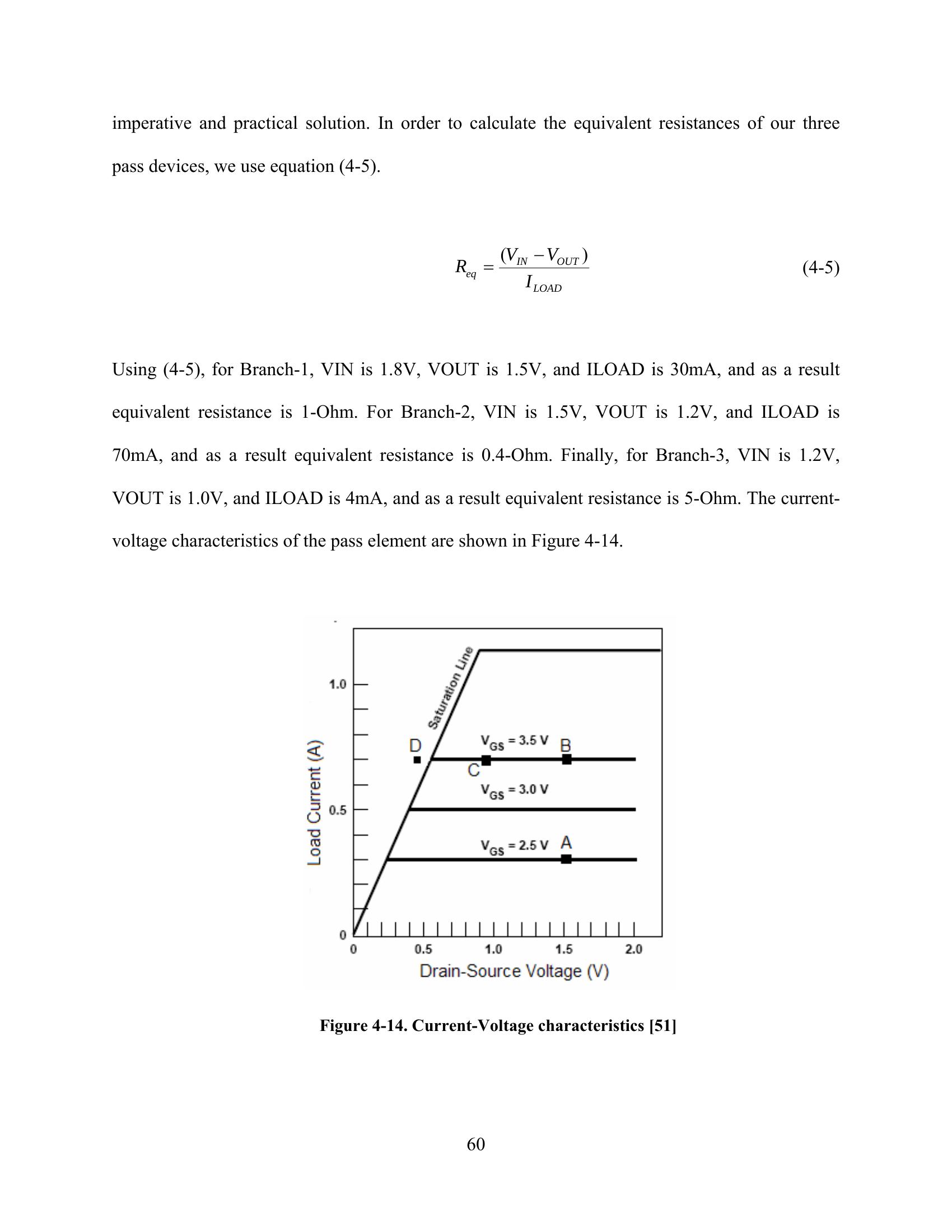

4.2.1 Pulse Width Modulation (PWM)

The duty cycle of the switching regulator is modulated by pulse width modulation in

order to control the amount of power sent to the load. It measures the output voltage and when it

is lower than the desired voltage of 3.7V it turns on the switch. When output voltage increases

above 3.7V, PWM turns off the switch. The desired output voltage is realized by switching

voltage to the load with the appropriate duty cycle. Since V is 3.7V and V is 1.8V then duty

IN OUT

cycle is 1.8V/3.7V=0.486. The step-down occurring is relatively small, from 3.7V to 1.8V,

therefore the operating duty cycle of the regulator is sufficient to maintain high regulator

efficiency. On the other hand, if the step-down was bigger, such as from 10V to 1.8V, then duty

cycle would be 1.8V/10V= .180, which is very small and makes it difficult to design a voltage

regulator with high efficiency. In addition, duty cycle is also dependent on t which is 1.94us,

on,

and period, T, which is 4us. So, efficiency of the regulator varies with duty cycle. An extreme

duty cycle challenges the design of an efficient regulator.

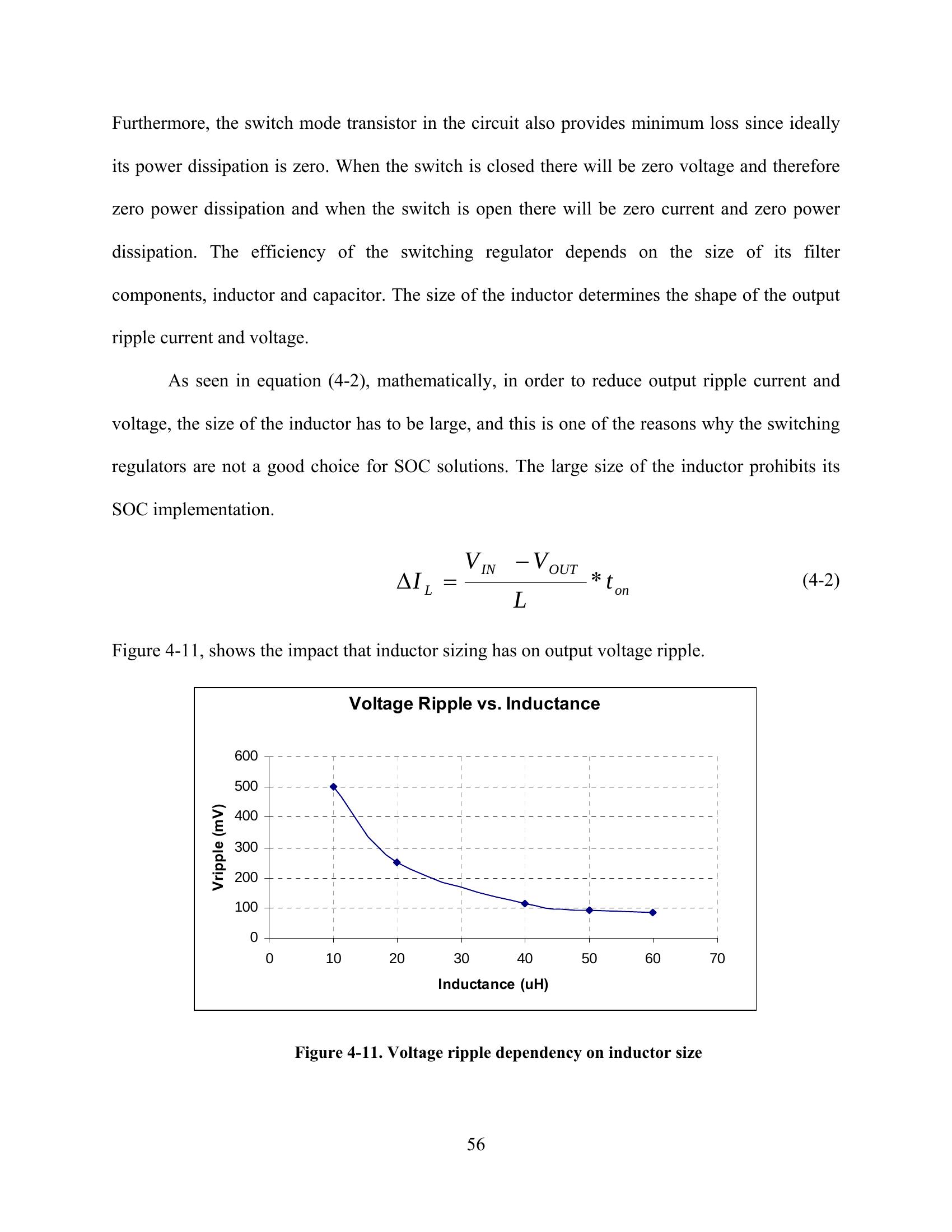

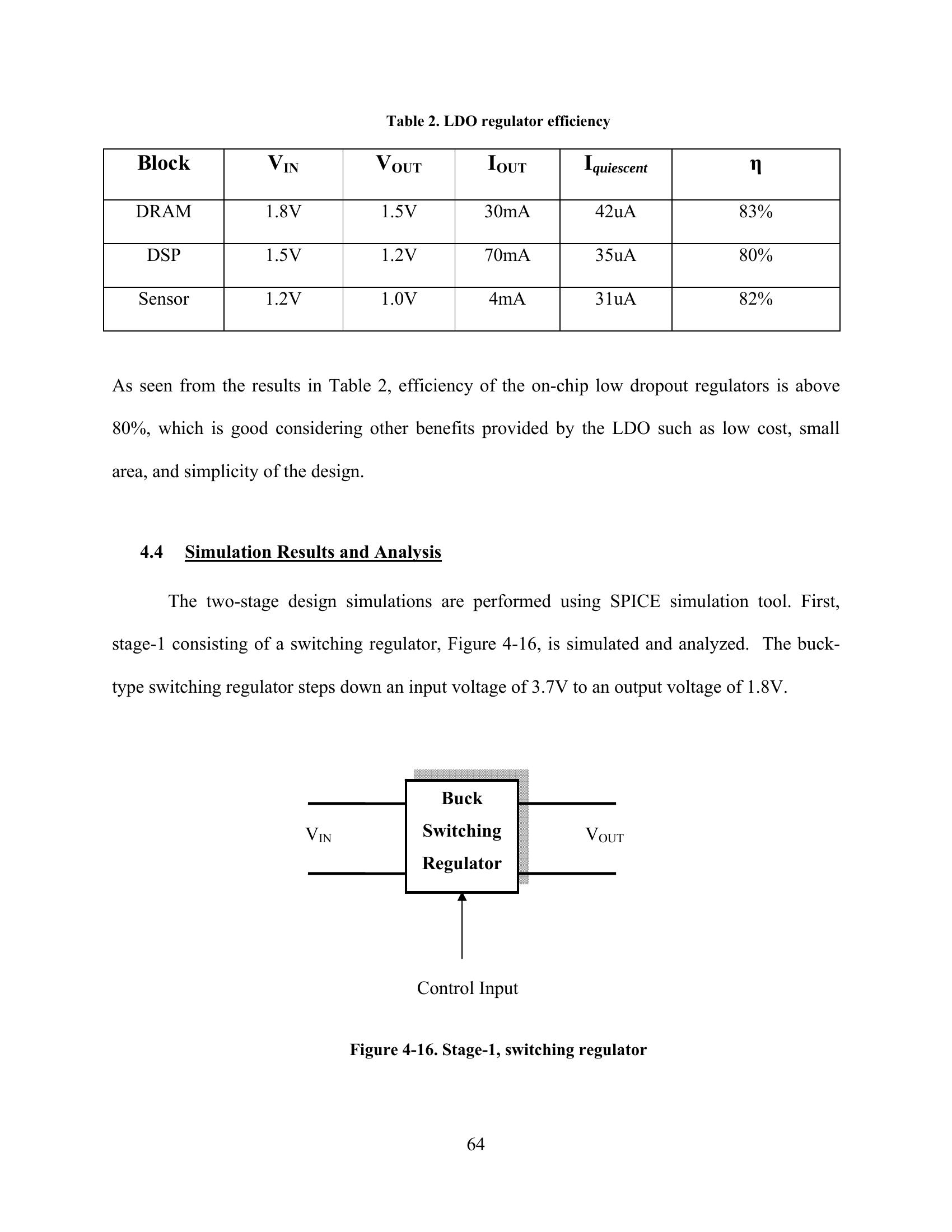

4.2.2 Switching Regulator Efficiency

Efficiency is one of the most important features of the switching regulator. The first stage

of the design needs to be very efficient since it will step down the battery voltage and also serve

as source for the on-chip LDO branches. The switching regulator provides high efficiency, given

by (4-1), because it employs an inductor that transfers energy from input to output in a lossless

manner.

P V * I

η= LOAD = OUT LOAD (4-1)

P V * I

TOTAL IN IN(AVE)

55

Furthermore, the switch mode transistor in the circuit also provides minimum loss since ideally

its power dissipation is zero. When the switch is closed there will be zero voltage and therefore

zero power dissipation and when the switch is open there will be zero current and zero power

dissipation. The efficiency of the switching regulator depends on the size of its filter

components, inductor and capacitor. The size of the inductor determines the shape of the output

ripple current and voltage.

As seen in equation (4-2), mathematically, in order to reduce output ripple current and

voltage, the size of the inductor has to be large, and this is one of the reasons why the switching

regulators are not a good choice for SOC solutions. The large size of the inductor prohibits its

SOC implementation.

V −V

IN OUT

∆I = *t (4-2)

L

L

on

Figure 4-11, shows the impact that inductor sizing has on output voltage ripple.

Voltage Ripple vs. Inductance

600

500

400

300

200

100

0

0 10 20 30 40 50 60 70

Inductance (uH)

56

)Vm(

elppirV

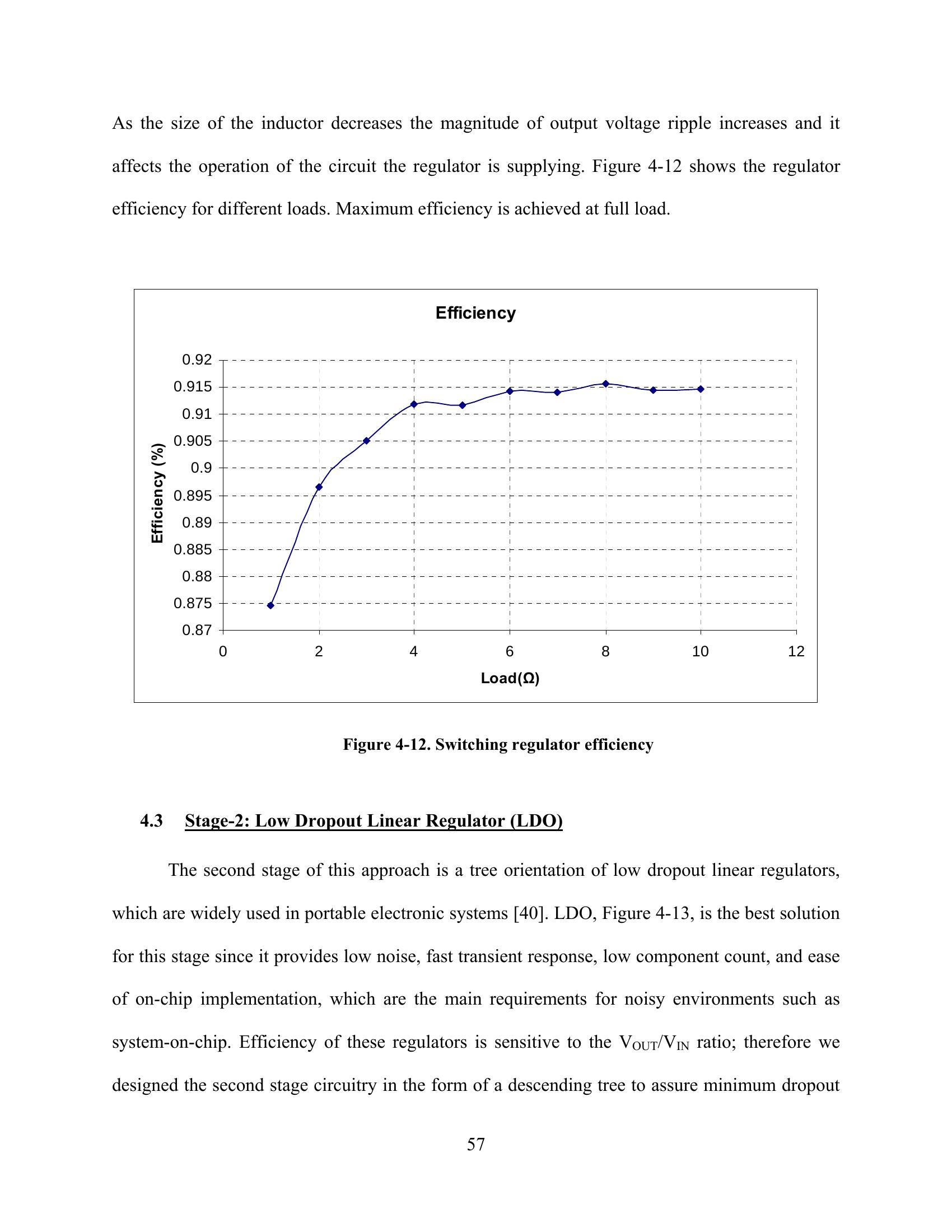

Figure 4-11. Voltage ripple dependency on inductor size

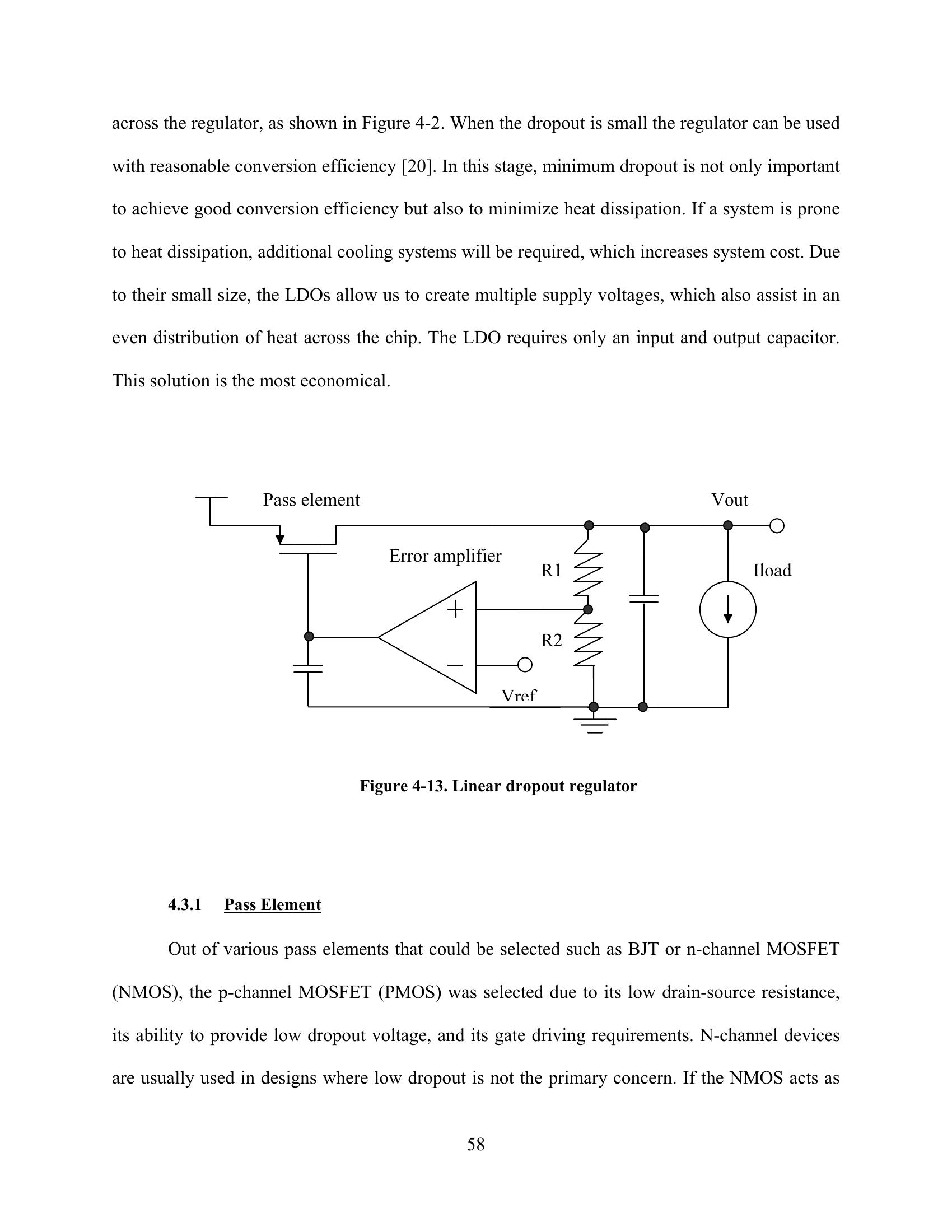

As the size of the inductor decreases the magnitude of output voltage ripple increases and it

affects the operation of the circuit the regulator is supplying. Figure 4-12 shows the regulator

efficiency for different loads. Maximum efficiency is achieved at full load.

Efficiency

0.92

0.915

0.91

0.905

0.9

0.895

0.89

0.885

0.88

0.875

0.87

0 2 4 6 8 10 12

Load(Ω)

57

)%(

ycneiciffE

Figure 4-12. Switching regulator efficiency

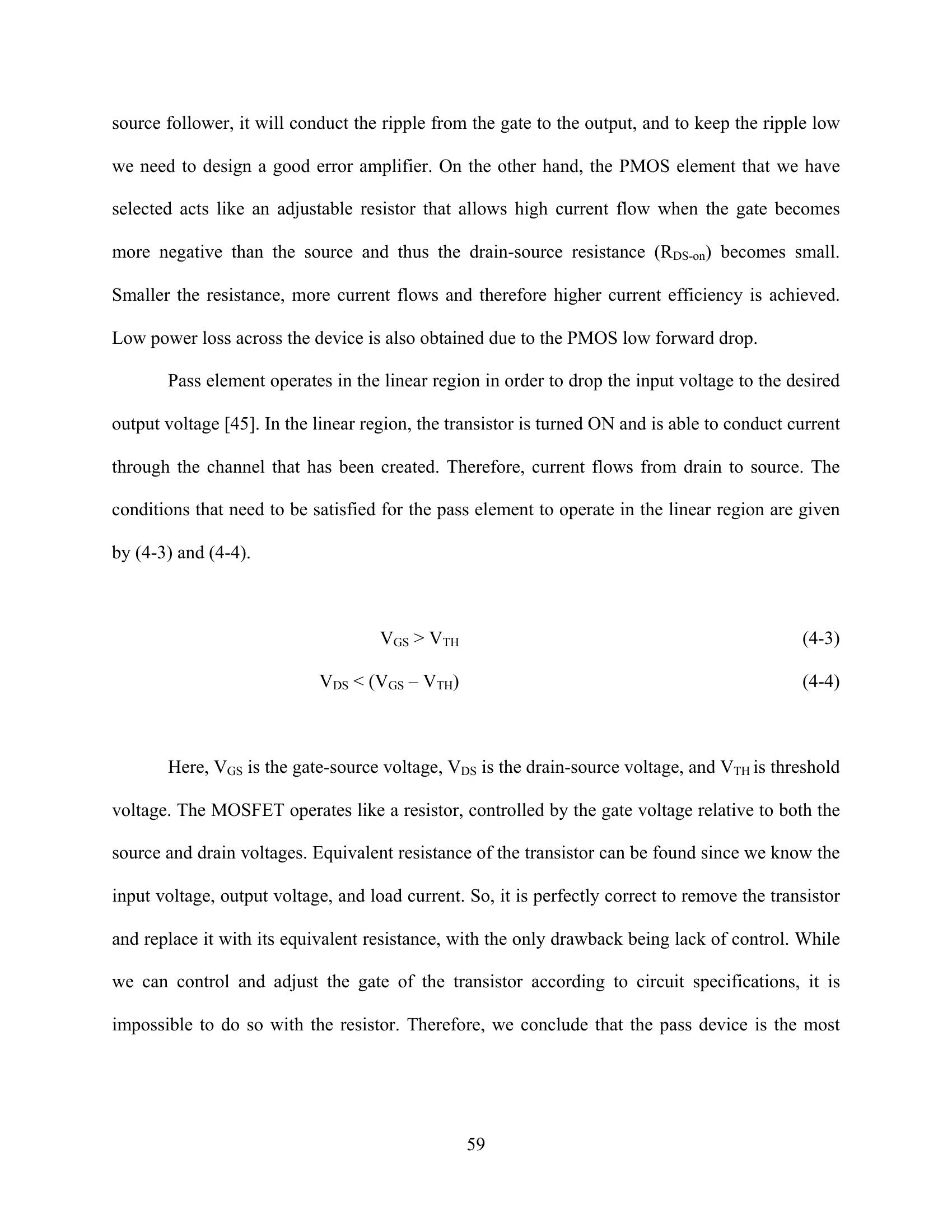

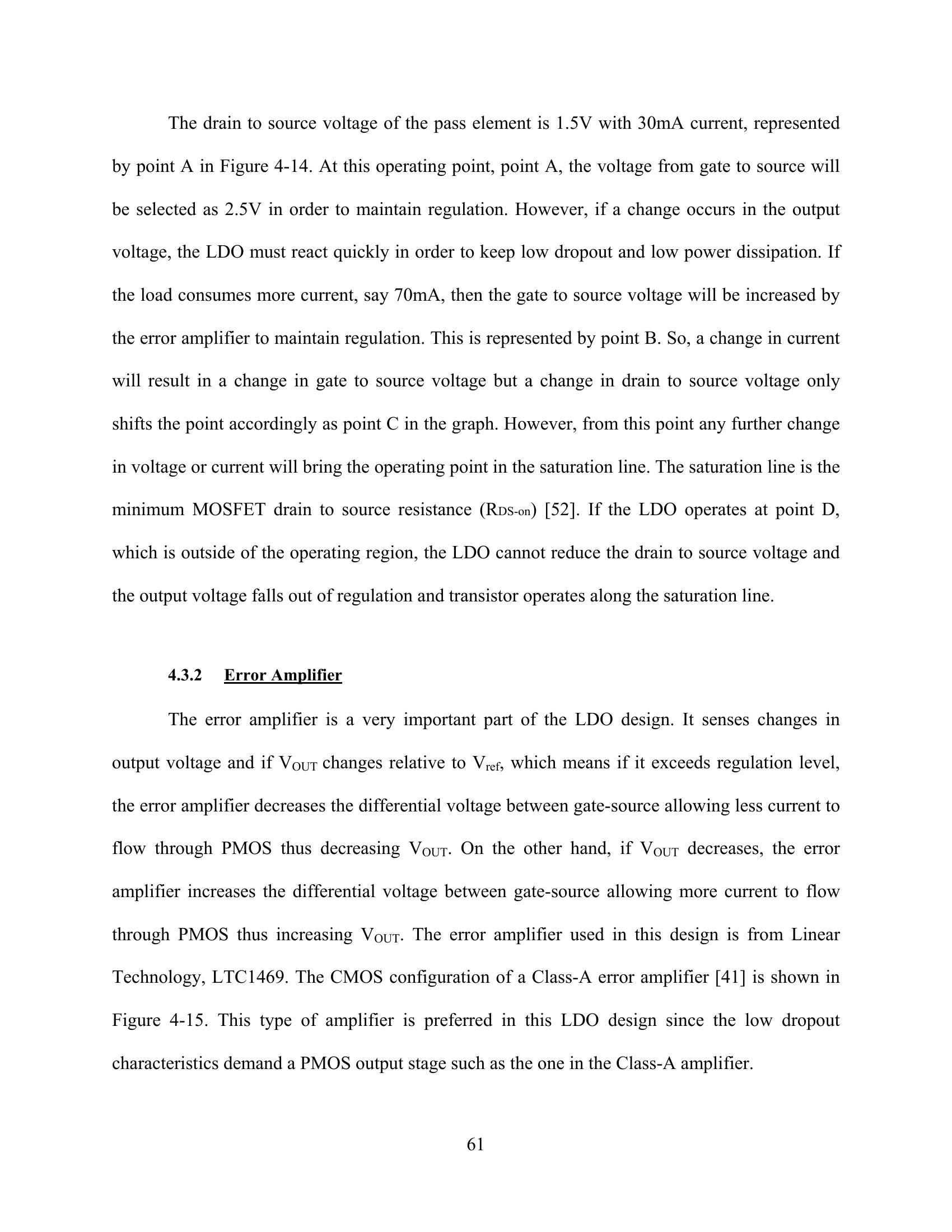

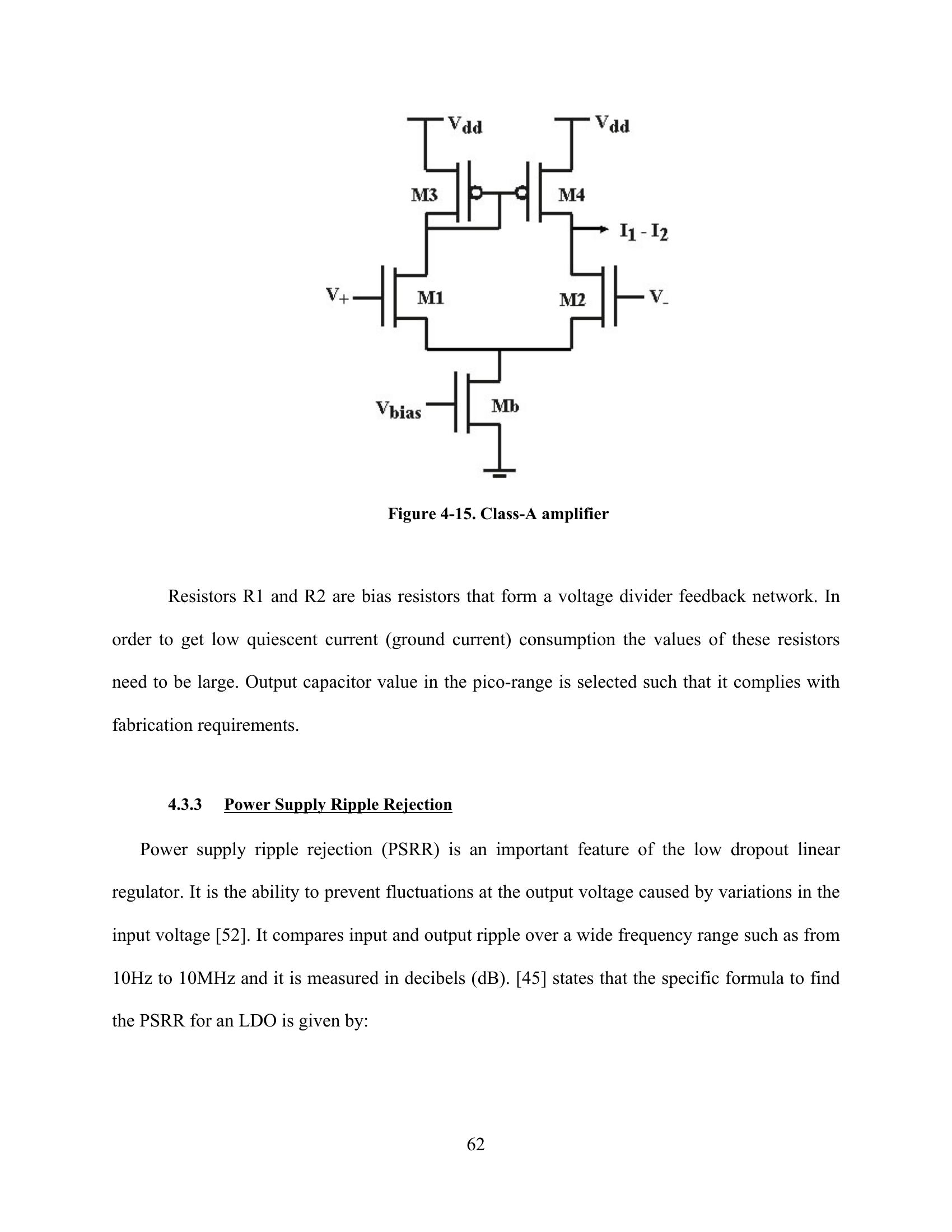

4.3 Stage-2: Low Dropout Linear Regulator (LDO)

The second stage of this approach is a tree orientation of low dropout linear regulators,

which are widely used in portable electronic systems [40]. LDO, Figure 4-13, is the best solution

for this stage since it provides low noise, fast transient response, low component count, and ease

of on-chip implementation, which are the main requirements for noisy environments such as

system-on-chip. Efficiency of these regulators is sensitive to the V /V ratio; therefore we

OUT IN

designed the second stage circuitry in the form of a descending tree to assure minimum dropout

across the regulator, as shown in Figure 4-2. When the dropout is small the regulator can be used

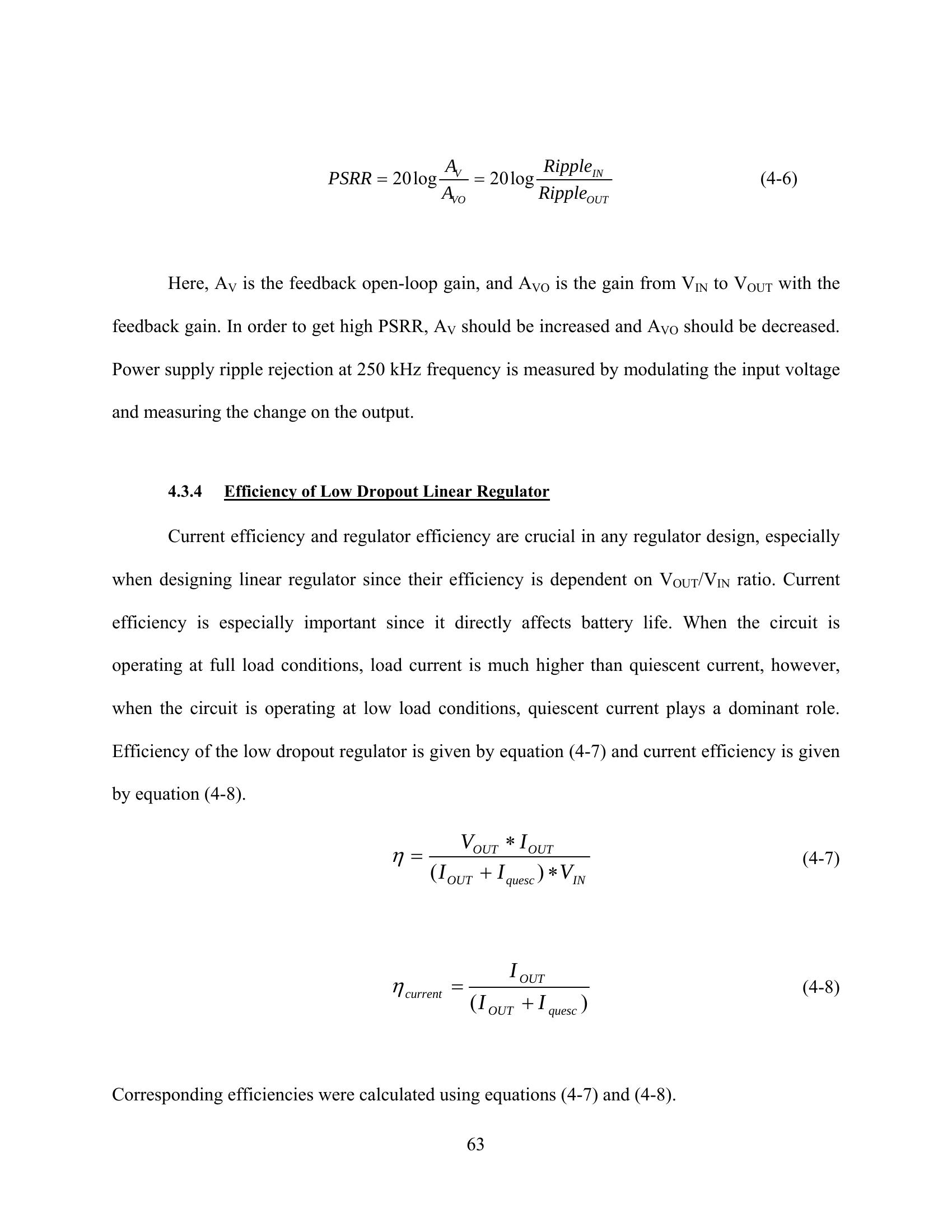

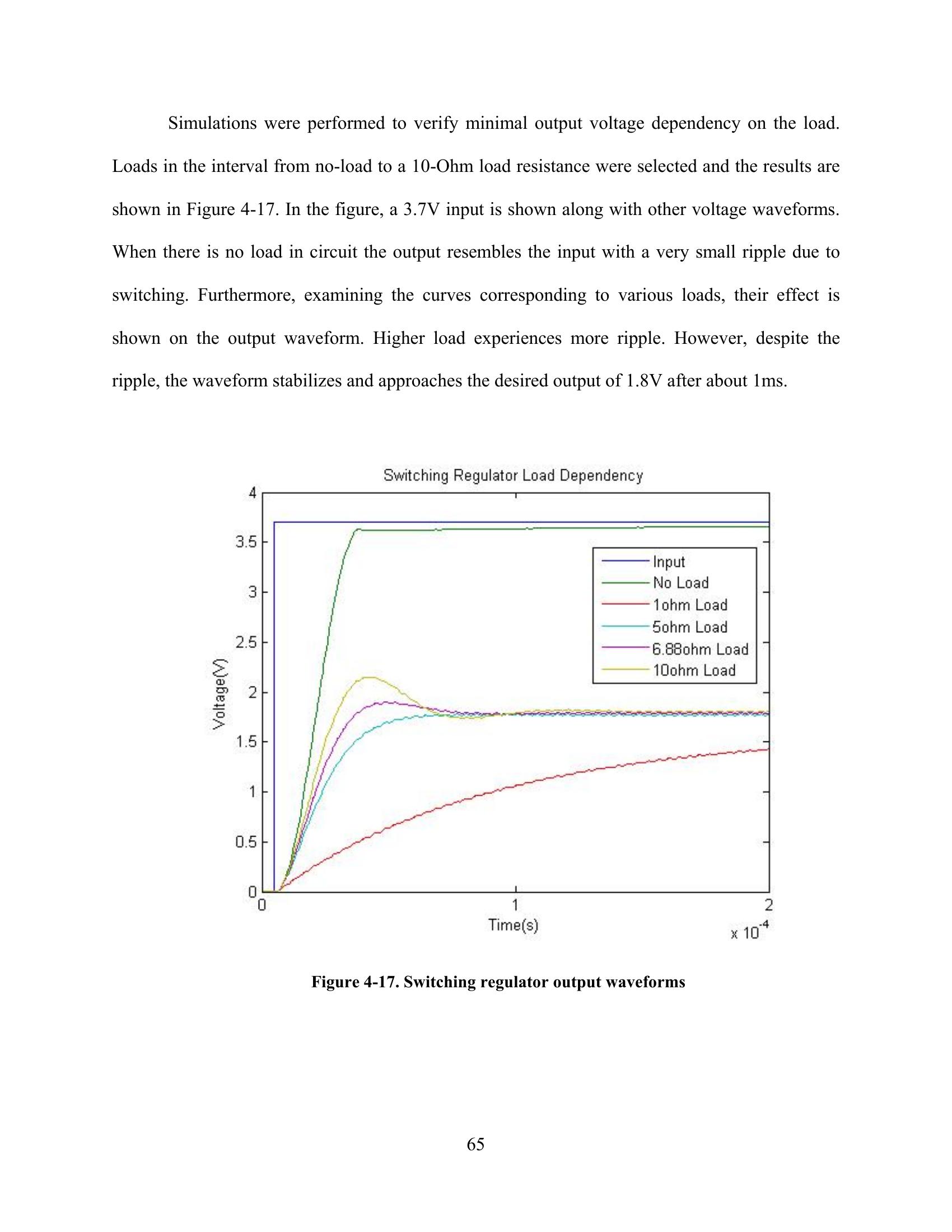

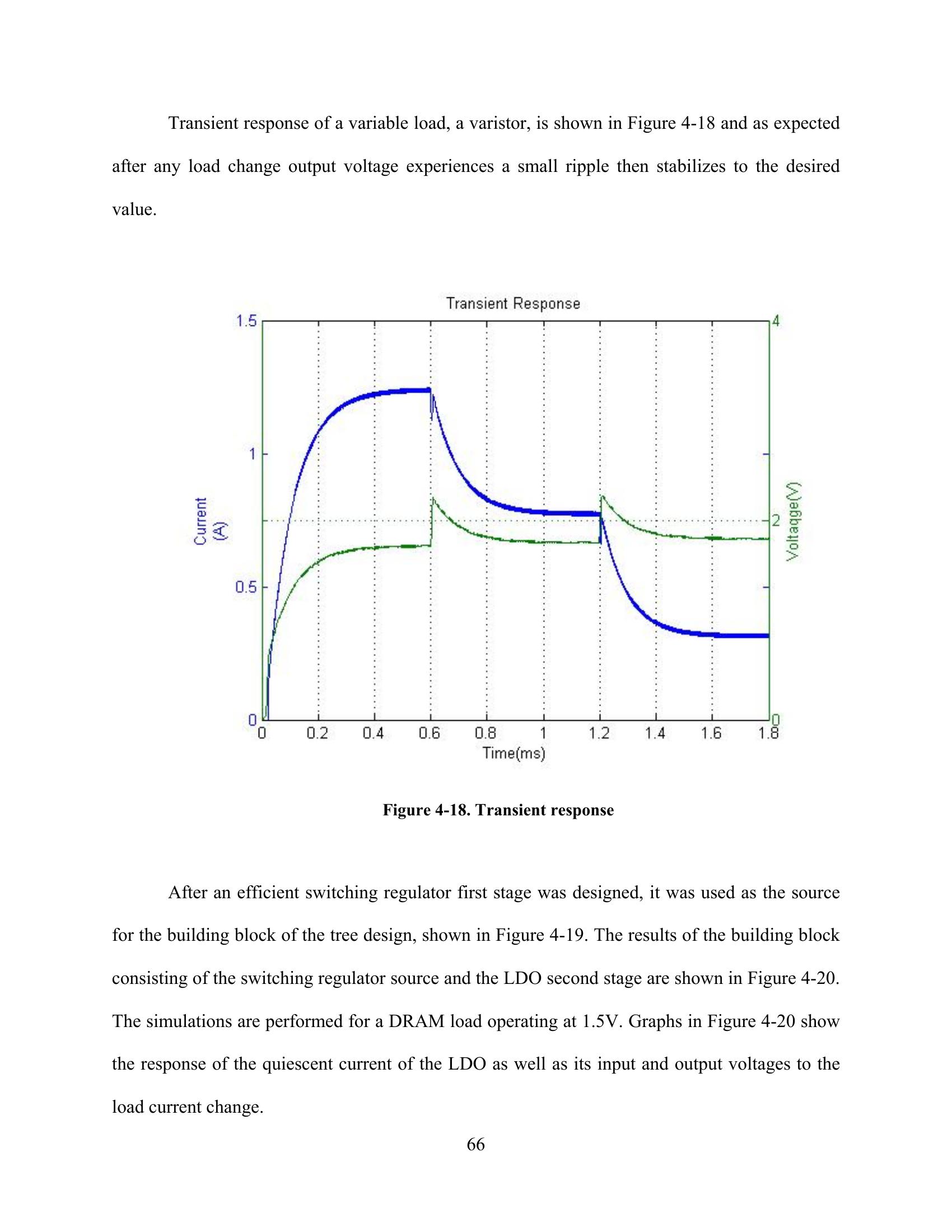

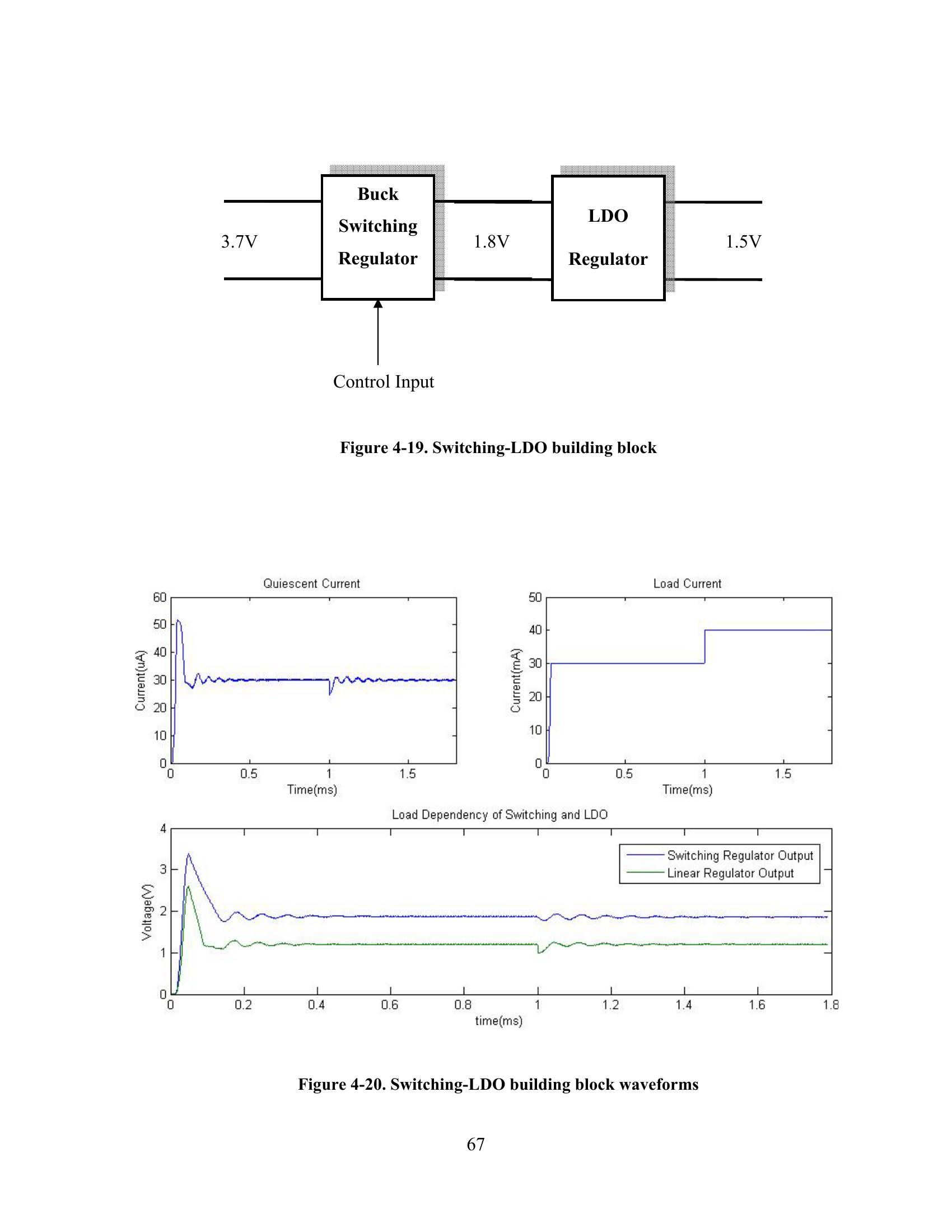

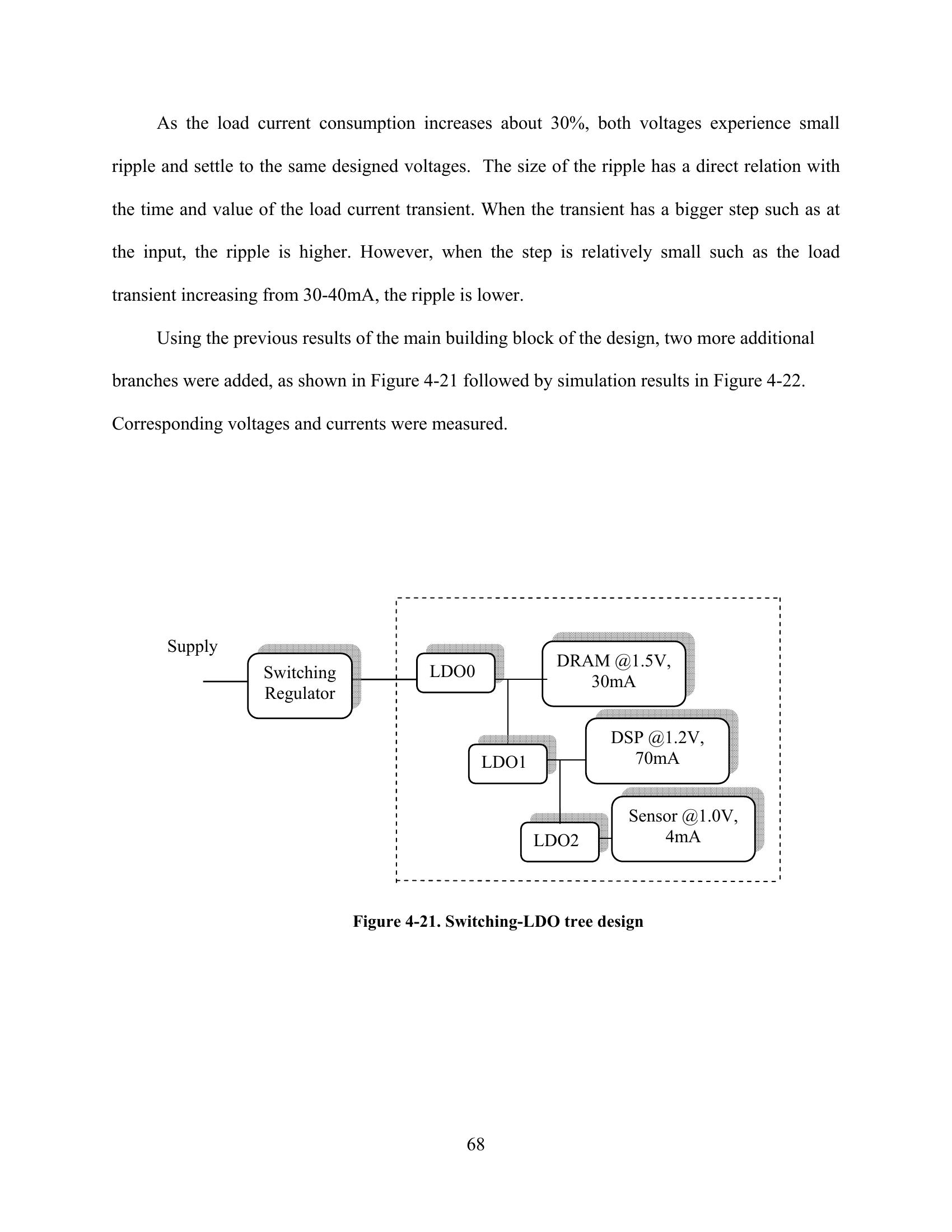

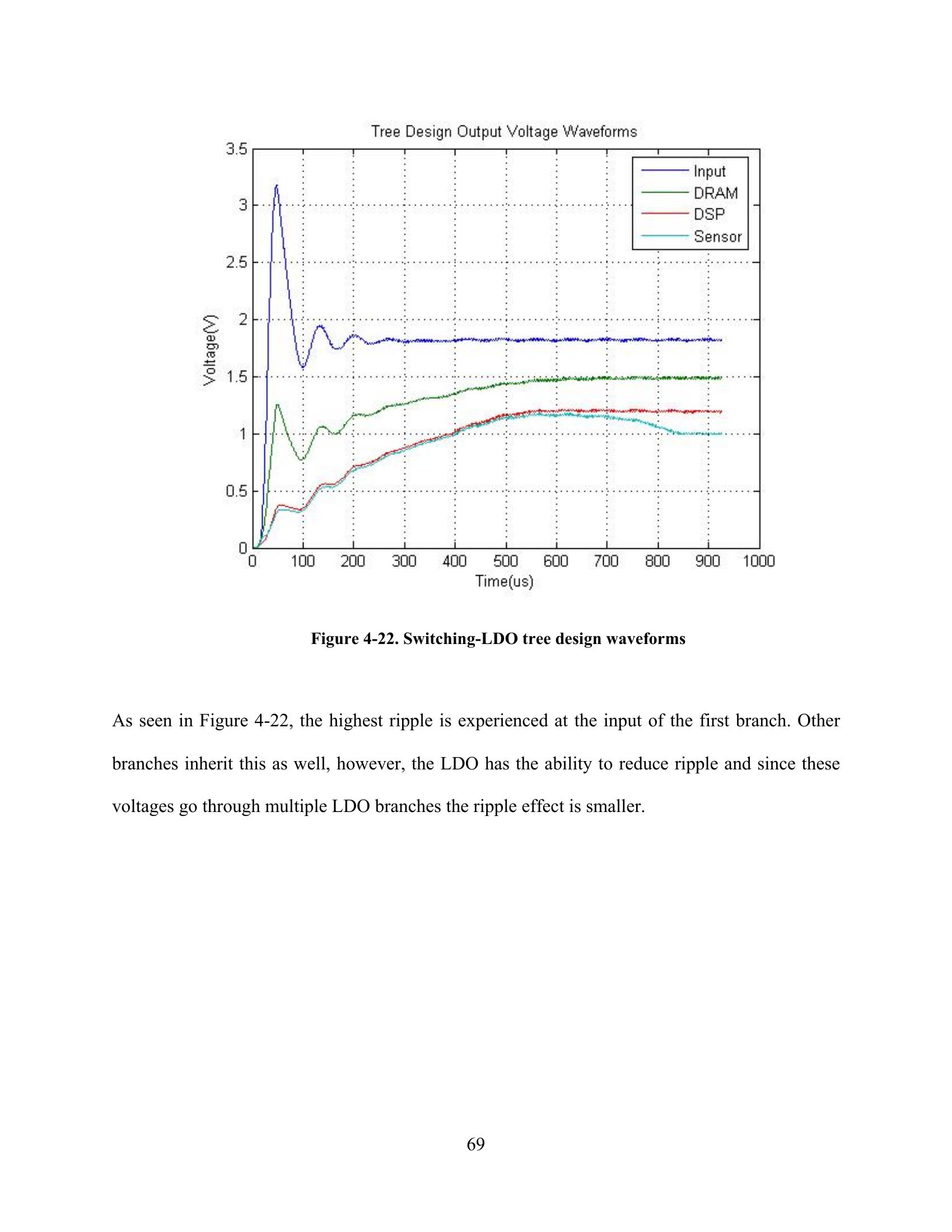

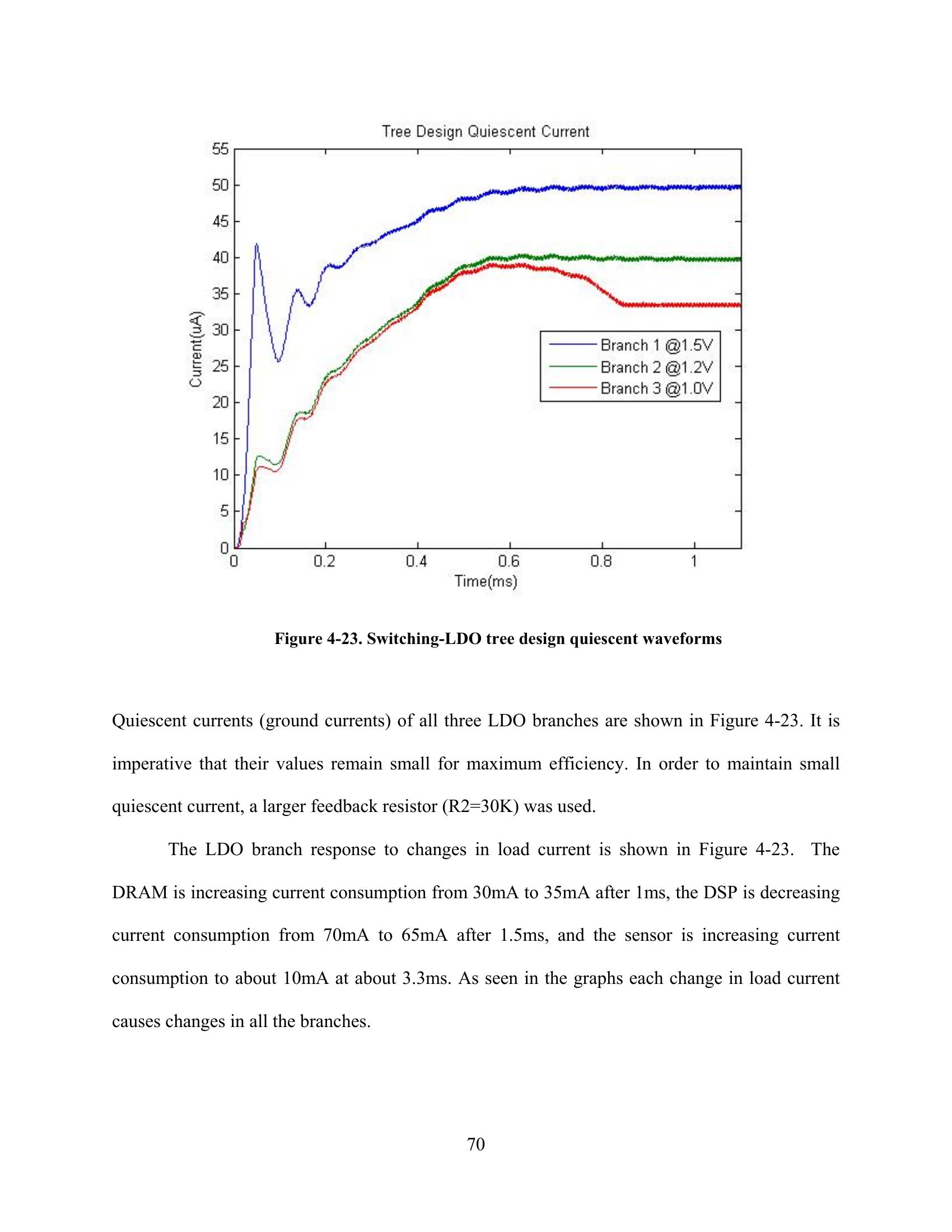

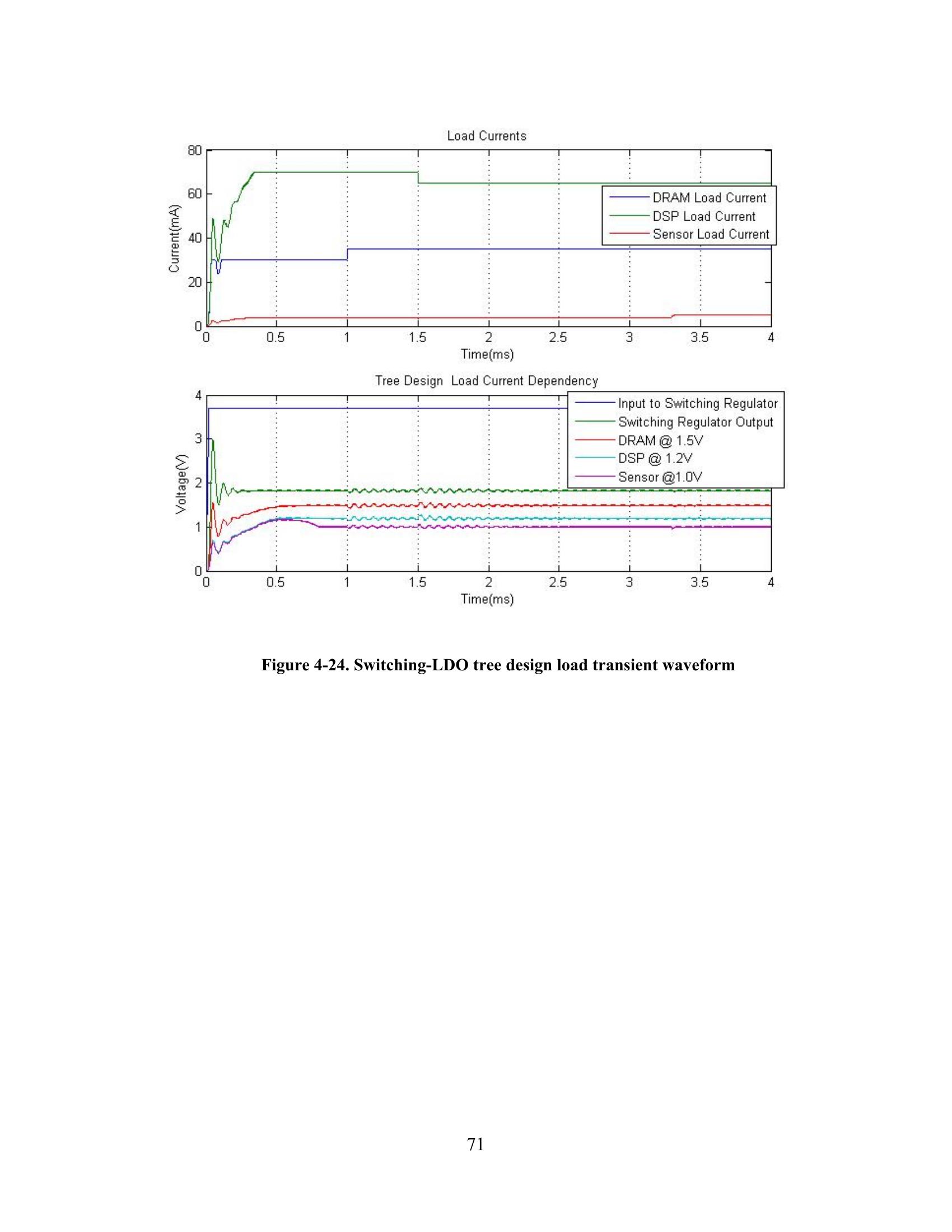

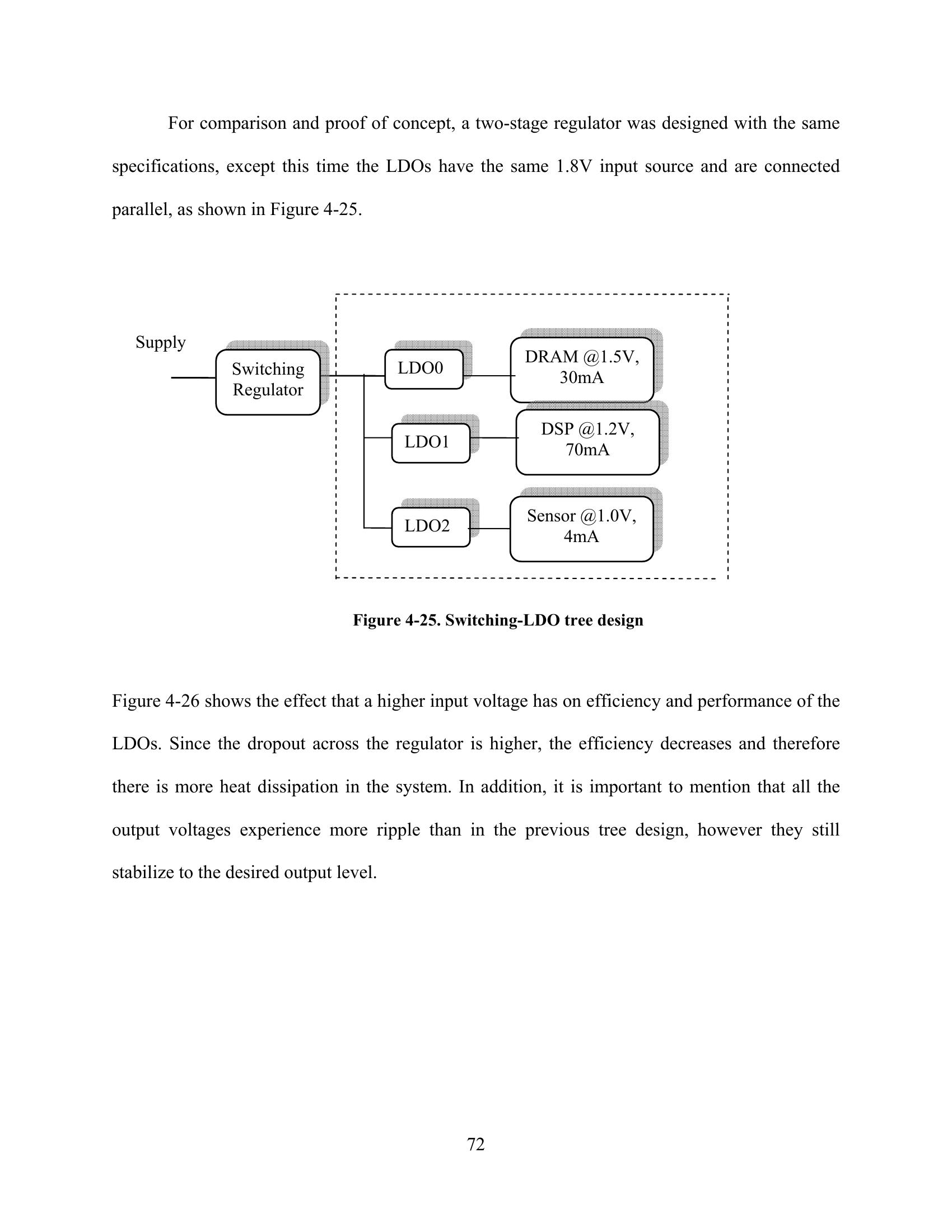

with reasonable conversion efficiency [20]. In this stage, minimum dropout is not only important